How UV light impacts PET containers and rPET options

What happens to PET bottles left outside for a year in Ohio? A study yields some surprising results that affect the viable options for the recovery and reuse of the polymer as rPET.

July 11, 2017

One of the problems that limits the amount of recycled PET (rPET) used in rigid packaging applications is the degree of yellowness that it can cause. The more rPET that is added to virgin PET during bottle manufacture, the more yellow the resulting bottle tends to become.

There are many other causes that also contribute to this problem. For example, it is known that low levels of nylon coming from multilayer bottles can remain trapped in the PET flake after washing and cleaning. This residual nylon will cause considerable yellowing when the rPET is extruded. The presence of additives such as ultraviolet (UV) light blockers, acetaldehyde and oxygen scavengers, and slip agents can all contribute to yellowing as the rPET is subjected to additional melt histories.

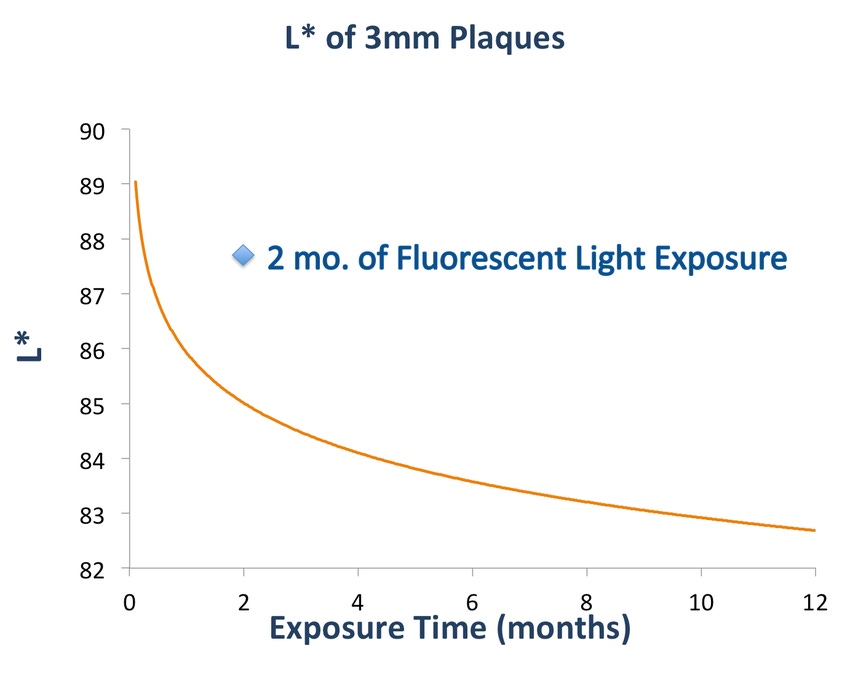

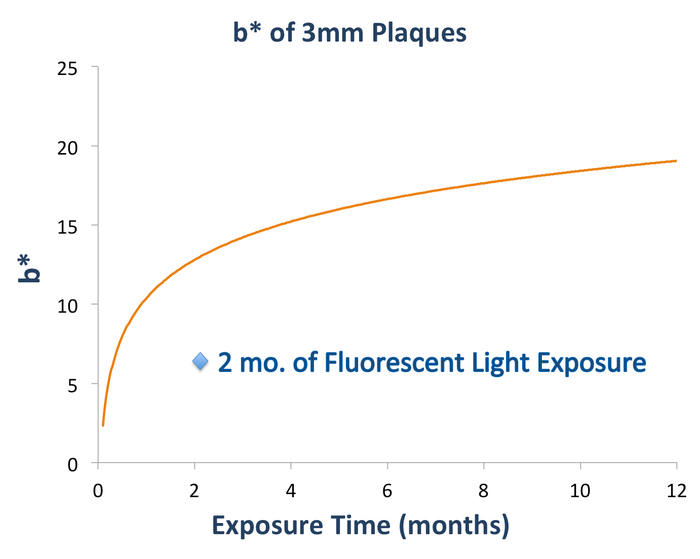

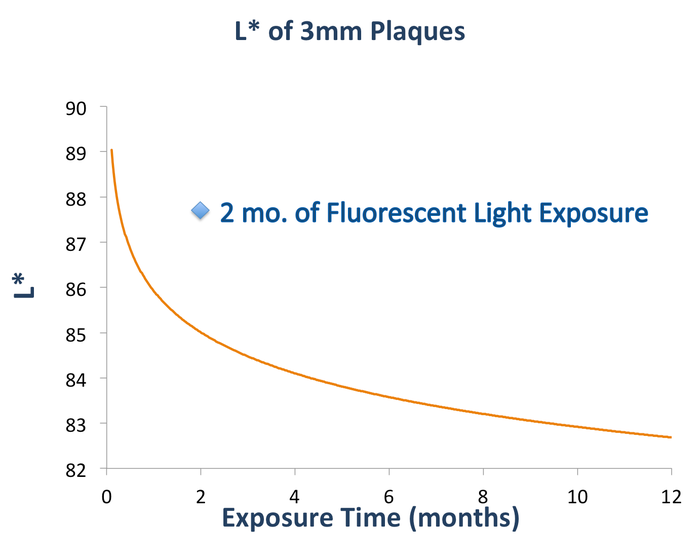

However, one cause of yellowing that has not been widely addressed is the effect that UV radiation from the sun, as well as that emitted by artificial sources, such as fluorescent lighting, can have on PET. PET is sensitive to UV light especially at elevated temperatures, under high humidity, and in the presence of oxygen—all of which are present when PET bottles are exposed to the weather.

In response, Plastic Technologies, Inc. (Holland, OH) undertook a study to understand the effects weathering would have on PET bottles exposed to Toledo, OH, weather for one year. Two-liter PET bottles produced using a commercial grade of PET that did not contain any UV- absorbing additives were used for this study. These virgin bottles were crushed, stacked five to six deep, and placed in uncovered open-sided crates to afford maximum exposure to the elements. These crates of bottles were then placed on the roof of Plastic Technologies, Inc. building in early January.

And the results were…

The data clearly shows that exposure to ultraviolet radiation was very damaging to the PET material. Sample flake was also measured for color before and after the one year exposure to determine if any obvious yellowing occurred.

Surprisingly, there was not a significant amount of yellowing seen in the color of the bottle flake. The yellowing only became significant after the weather exposed PET has been subjected to melting required for molding the plaques.

In conclusion, the results of this study demonstrate that storing bottles outside with direct exposure to sunlight in humid environment can have a severe effect on the L*, b* and IV properties of recycled PET. The bottles used in this study were not densely packed into large bales, thus sunlight could easily penetrate through the several layers of bottle sidewalls reaching even the bottles located at the bottom of the open crate.

What this means…

High-quality (clear, non-yellow) rPET is in high demand for food and non-food rigid packaging. The best rPET material available in the market today derives from deposit-grade PET bottle material. However, there is a limited supply of that material available for brand owners and converters to use. Curbside material must fulfill the remaining demand.

Also, curbside rPET bottles typically do not result in as high a quality rPET for reuse compared to deposit grade rPET. All PET bottles—both deposit and curbside—tend to show an increase in yellowness when being reprocessed into rPET for reuse where curbside bottles will develop more yellowness than deposit grade. There has been much debate and numerous studies done to better understand the cause of this increased yellowness. The findings have shown that certain additives such as ultraviolet light blockers, oxygen scavengers, nylon multilayer structures, residual label adhesives remaining on the cleaned flake, along with some inks and coatings from the labels, can all contribute to rPET yellowing.

The study that was performed by PTI determined that sunlight and fluorescent lighting could also contribute to the development of yellowing during the melt reprocessing of these bottles as well. There are MRFs and reclaimers that store baled bottles outside where these are subject to the effects of sunlight. Additionally, bottles exposed to artificial lighting (whether in warehouses or stores) were also seen to yellow more during their reprocessing. So basically the study simply pointed out yet another source of yellowing that seemingly has been overlooked that can cause rPET yellowing during reprocessing for use into recycle content packaging.

The yellowing caused by natural or artificial light might be mitigated to some degree by incorporating more or improved stabilizers into the PET during its manufacture. But this would probably add additional cost to virgin PET and in today’s market, an additional cost that may not be well accepted by brand owners or converters.

Frank Schloss, Ph.D., materials evaluation group, Plastic Technologies, Inc., has more than 30 years of experience working in the plastics packaging industry in analytical testing, closure development and applied materials research covering a wide range of materials including PE, PP, PVC, TPE, TPO, PLA and PET.

About Plastic Technologies

Plastic Technologies, Inc. (PTI) is recognized worldwide as a leading resource for preform and package design, package development, rapid prototyping, pre-production prototyping, and material evaluation engineering for the plastic packaging industry. For more information contact www.plastictechnologies.com, [email protected] or 419-867-5424.

About the Author(s)

You May Also Like