Latest

This Earth Day Supporter Gave Us . . . Plastic

This Earth Day Supporter Gave Us . . . Plastic

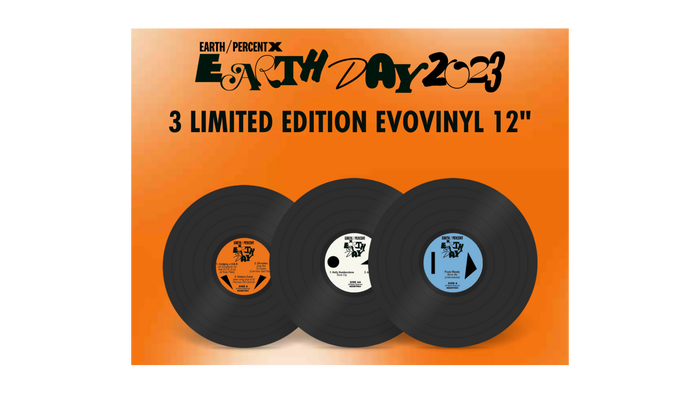

A famous and highly influential musician and producer who enlists music in the fight for climate causes presses records made from a plant-based plastic through his charity. So far, so good, until you read the fine print.

The company is bringing its new mobile manipulators and autonomous mobile robots to NPE2024.

Hot Right Now

A famous and highly influential musician and producer who enlists music in the fight for climate causes presses records made from a plant-based plastic through his charity. So far, so good, until you read the fine print.

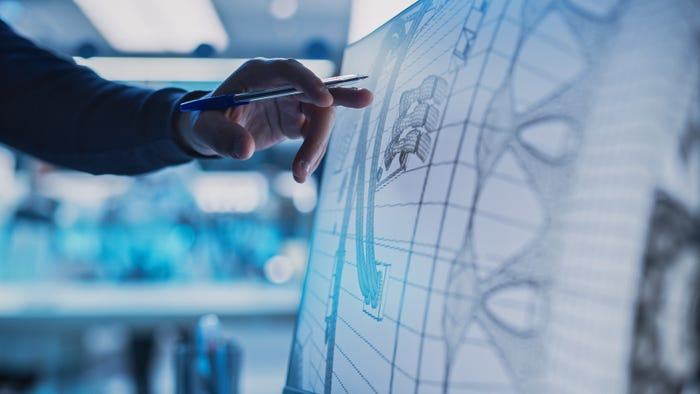

In the first of this two-part series, design engineer Michael Paloian details key considerations in specifying screw fasteners for plastics, including the type of screw, size, length, and material.

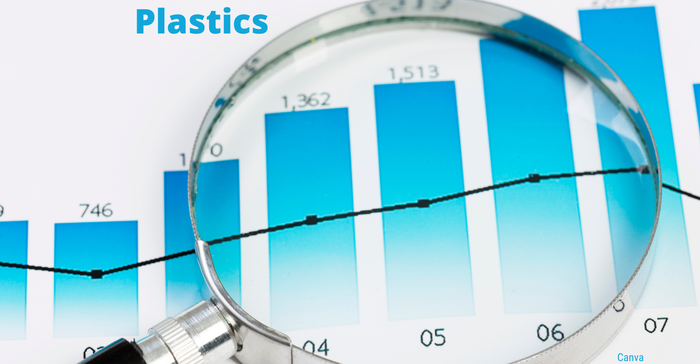

Plastics market reports for thermoform packaging, thin-wall packaging, polyethylene furanoate (PEF), functional films, PCR plastics, and more are featured in this slideshow.

Popular

Recent