New Polyamide a Game Changer in Fuel-Cell Cooling-Circuit Performance

A material advancement at Domo Chemicals has potential to increase fuel-cell service life and lengthen coolant-filter replacement requirements.

February 16, 2024

At a Glance

- Domo demonstrates Technyl polyamides effectively limit ion migration, helping reduce conductivity of fuel coolant

- Technyl Pure outperforms reference materials in hydrogen fuel-cell cooling-circuit performance

Engineered materials and sustainable solutions provider Domo Chemicals has made a landmark breakthrough with its Technyl polyamides (PAs), drastically reducing coolant conductivity in hydrogen fuel-cell stacks. This innovation, supported by comprehensive testing, establishes Technyl as the premier choice for enhancing fuel-cell stack performance and durability.

Historically, polyamides were not considered optimal for cooling circuits in hydrogen fuel-cell technology owing to concerns about ion leaching and increased coolant conductivity. However, Domo's latest research overturns these assumptions, demonstrating that Technyl PAs effectively limit ion migration, thereby maintaining lower coolant conductivity and extending system longevity.

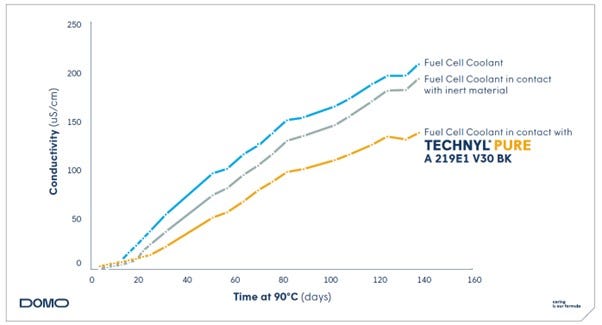

Lower coolant conductivity through interaction with polyamide significantly enhances system longevity, leading to a five- to six-fold increase in the lifetime of ion filters used in fuel-cell stacks. Graphic courtesy of Domo Chemicals.

"Our research reveals the 'polyamide paradox,'" says Maarten Veevaete, director of the application center at Domo. "Contrary to previous beliefs, Technyl grades have a positive impact on the fuel-cell cooling circuit. Their chemical interaction with the coolant reduces its conductivity, significantly enhancing system longevity and leading to a five- to six-fold increase in the lifetime of ion filters. This effectively reduces maintenance requirements and associated costs," adds Veevaete.

Technyl Pure, a top-tier formulation designed to minimize ion leaching, consistently maintains lower coolant conductivity from the outset. This innovative material surpasses traditional solutions, offering a more efficient and durable option for hydrogen fuel-cell cooling loops.*

The Technyl range for the fuel-cell cooling circuit caters to specific customer requirements, offering a variety of grades, including PA 6 and PA 66-based alternatives alongside the flagship Technyl Pure.

*Calculation based on a commercial vehicle lifetime of 500,000 km, with a filter change every 90,000 km at a battery operating temperature of around 80°C.

About the Author(s)

You May Also Like