Oak Ridge Scientists Develop Recyclable Super-tough CFRP

The composite material is based on a borylated SEBS copolymer and delivers a tensile strength of 731 MPa.

February 23, 2024

At a Glance

- Dynamic crosslinking is key to recoverability of component materials

- Licensees seek to apply material to automotive, aerospace, and other applications

- Research group also plans to apply technology to glass-fiber composites

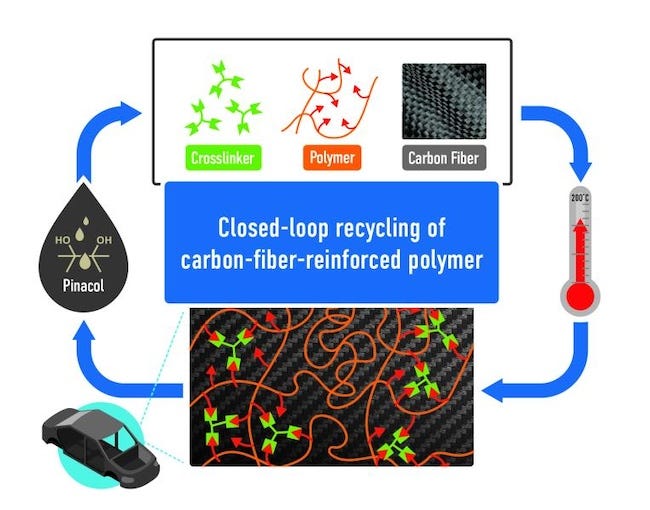

Scientists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have designed a closed-loop path for synthesizing an exceptionally tough carbon-fiber-reinforced polymer (CFRP), and later recovering all of its starting materials.

CFRP is useful for reducing weight and increasing fuel efficiency of automobiles, airplanes, and spacecraft. However, conventional CFRPs are difficult to recycle. Most have been single-use materials, so their carbon footprint is significant. By contrast, ORNL’s closed-loop technology, which is published in Cell Reports Physical Science, accelerates addressing that grand challenge.

Dynamic crosslinking

“We incorporated dynamic crosslinking into a commodity polymer to functionalize it. Then, we added a crosslinker to make it like thermoset materials,” said ORNL chemist and inventor Md Anisur Rahman. “Dynamic crosslinking allows us to break chemical bonds and reprocess or recycle the carbon-fiber composite materials.”

The scientists found that the degree of dynamic crosslinking is important. “We found 5% crosslinking works better than 50%,” Rahman said. “If we increase the crosslinker amount, it starts making the polymer brittle. That’s because our crosslinker has three hand-like bulky structures, able to make more connections and decrease the polymer’s flexibility.”

A polymer, functionalized carbon fibers, and crosslinker are mixed and cured. The components can be retrieved by addition of an alcohol, pinacol. Image courtesy of Philip Gray and Anisur Rahman/ORNL, US Dept. of Energy.

A conventional thermoset material is permanently crosslinked. Once synthesized, cured, molded, and set into a shape, it cannot be reprocessed. ORNL’s system, on the other hand, adds dynamic chemical groups to the polymer matrix and its embedded carbon fibers. The polymer matrix and carbon fibers can undergo multiple reprocessing cycles without loss of mechanical properties, such as strength and toughness.

Rahman led the study with ORNL chemist Tomonori Saito, who was honored by Battelle in 2023 as ORNL Inventor of the Year. Rahman and ORNL postdoctoral fellow Menisha Karunarathna Koralalage conducted most of the experiments. The trio has applied for a patent for the innovation.

“We invented a tough and recyclable carbon-fiber composite,” said Saito. “The fiber and the polymer have a very strong interfacial adhesion due to the presence of dynamic bonds.” The interface locks materials together through covalent interactions and unlocks them on demand using heat or chemistry. Saito added: “The functionalized fiber has dynamic exchangeable crosslinking with this polymer. The composite structure is really tough because of the interface characteristics. That makes a very, very strong material.”

Alcohol releases material’s components

Conventional polymers, like thermoset epoxies, are typically used to permanently bond materials such as metal, carbon, concrete, glass, ceramic, and plastic to form multicomponent materials such as composites. However, in the ORNL material, the polymer, carbon fibers, and crosslinker, once thermoset, can be reincarnated back into those starting materials. The material’s components can be released for recycling when a special alcohol called pinacol replaces the crosslinker’s covalent bonds.

Closed-loop recycling at laboratory scale results in no loss of starting materials. “When we recycle the composites, we recover 100% of the starting materials — the crosslinker, the polymer, the fiber,” Rahman said. “That’s the importance of our work,” Saito said. “Other composite recycling technologies tend to lose the component starting materials during the recycling process.” Other advantages of the reversibly crosslinked CFRPs are quick thermosetting, self-adhesive behavior, and repair of microcracks in the composite matrix.

Highest tensile strength ever

The researchers also aimed to optimize interfacial chemistry between the carbon fibers and the polymer matrix to boost interfacial adhesion and enhance CFRP toughness. “Our composite’s strength is almost two times higher than a conventional epoxy composite,” Rahman said. “Other mechanical properties are also very good.”

The tensile strength of 731 MPa was the highest ever reported among similar fiber-reinforced composite materials, meaning it was stronger than stainless steel and stronger than a conventional epoxy-based CFRP composite for automobiles.

The matrix material employed is a borylated styrene ethylene butylene styrene (SEBS) triblock copolymer that incorporates boronic ester groups that covalently bond with a crosslinker and fibers to generate the tough CFRP.

Glass-fiber composite the next step

Next, the research team would like to conduct similar studies with glass-fiber composites, which maintain high performance while lowering the cost and carbon footprint of applications in aerospace, automotive, marine, sporting, construction, and engineering. They also hope to reduce costs of the new technology to optimize commercial prospects for a future licensee. “This step will open more applications, especially for wind turbines, electric vehicles, aerospace materials, and even sporting goods,” Rahman said.

About the Author(s)

You May Also Like