AI-powered Conveying Technology Helps Plastics Processors Bridge Labor Gap

Conair invites NPE2024 attendees to a hands-on demonstration of its labor- and cost-saving auxiliary equipment.

March 19, 2024

Conair will put its AI-driven conveying technology front and center at NPE2024, along with 12 new products, more than 55 pieces of equipment, and more than a dozen interactive demos from May 6 to 10 in Orlando, FL.

It will be the company’s largest, most interactive product introduction — and attendees are invited to bring their most difficult conveying issues to the booth to discover how to eliminate them with Conair’s AI-driven solution.

Live demos of AI conveying technology

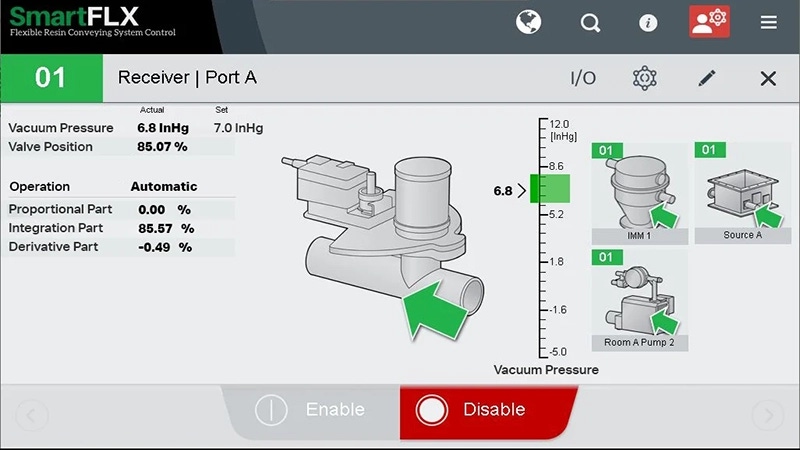

In a live, interactive display, Conair will give attendees hands-on experience with its patented AI conveying technology, which creates and maintains material flows while automatically compensating for common conveying issues. Operators simply tell the conveying controller where to send materials, and the system carries out the request — no matter the distance, destination, or material characteristics.

“At Conair, we have always sold auxiliary equipment to processors with the understanding that it’s going to provide labor savings and increased productivity,” said Sam Rajkovich, vice president of sales and marketing. “Our latest products, including our AI-driven conveying technology, offer processors a practical, affordable, and technically advanced way to meet high labor training and turnover costs head-on.

AI conveying eliminates error-prone manual operations

“Investing in this product is going to directly save labor and simplify training because artificial intelligence will not only optimize the process of conveying, but also will eliminate labor costs — specifically the need for error-prone manual interactions with the conveying equipment,” added Rajkovich.

With products covering eight facets of plastics production under the theme “Make Every Pellet Count,” Conair also will feature working medical and filament extrusion lines.

Visit Conair at booth W2113 during NPE2024 at the Orange County Convention Center in Orlando, FL.

About the Author(s)

You May Also Like