Long-Fiber Polyamide Composites Boast Enhanced Appearance

Avient’s Complēt moisture-resistant polyamide features smooth surfaces that are virtually free of visible fiber.

July 16, 2021

Compounder Avient has debuted a series of polyamide-based Complēt long-fiber-reinforced thermoplastic composites with enhanced moisture resistance and smooth surface aesthetics. These formulations feature polyamide 6 and 6/6 with delayed moisture absorption, which prolongs the effectiveness of their structural performance in moisture-rich environments.

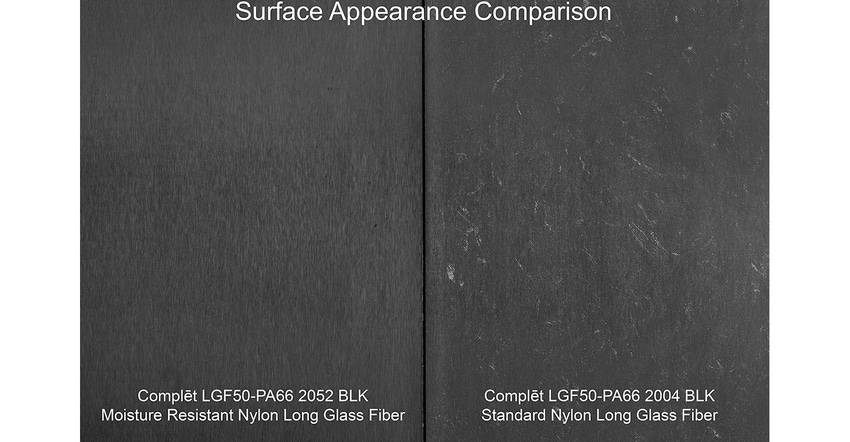

These new materials also take aim at inconsistent surface appearance issues with long-fiber polyamides, which have affected quality perceptions in the past. Long glass-fiber-reinforced grades of Complēt moisture-resistant polyamide feature surfaces that are smooth and virtually free of visible fiber, making them suitable for a range of consumer applications.

Complēt moisture-resistant polyamide 6 and 6/6 grades are globally available in several fiber-loading levels (weight percentages) using long glass fiber, long carbon fiber, or hybrid combinations. This allows the materials to retain structural properties that fall between those of standard and specialty polyamides when exposed to moisture. As a result, the materials are ideal for metal replacement and lightweighting initiatives in automotive and power sports applications that encounter varying climates or intermittent exposure to water.

“When manufacturers wanted to quell performance concerns by limiting moisture absorption for polyamide 6 or 6/6, the only options were less hygroscopic and more costly specialty polyamides,” said Eric Wollan, General Manager of Avient’s long-fiber technologies. “Avient’s new line of moisture-resistant polyamide LFTs are modified to absorb moisture more slowly. This significantly prolongs the effectiveness of a part’s structural capabilities in humid environments or during short-term water immersion, but at a more economical price point.”

Additionally, the Complēt grades provide lower shrink for applications that require high dimensional stability. In effect, they serve as a material solution to combat warp distortion from uneven cooling.

About the Author(s)

You May Also Like