Thermally Conductive Polymers Help Handle the Heat in Today’s Electronics

From computer circuit boards to vehicle headlamps and bicycle-seat vision systems, thermally conductive polycarbonate is a game changer.

March 17, 2024

At a Glance

- Overmolding single-board computers with thermally conductive PC can replace metal heat sinks

- PC heat sinks can be part of an in-mold assembly process, reducing weight and labor in some applications

- Pittsburgh firm leverages technology to develop AI-powered bicycle light and camera

Electronics makers continue to pack more power into ever-smaller form factors. And, increasingly, they are also adding artificial intelligence (AI) capabilities to their products. This may offer benefits to the consumer, but it also raises the stakes when it comes to keeping device temperatures down as computing power rises.

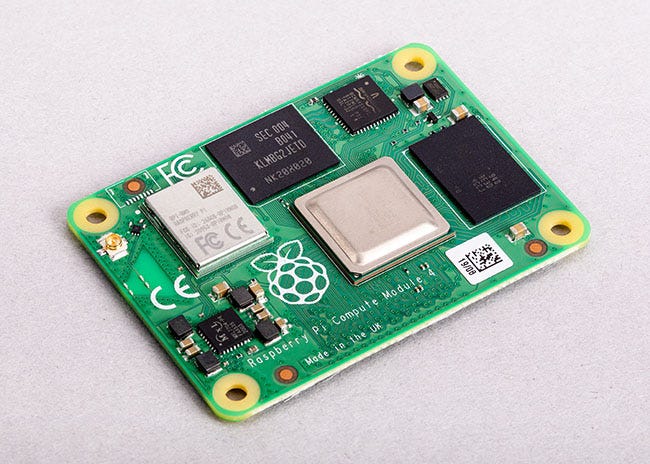

Just ask Eben Upton, CEO of Raspberry Pi Ltd. The UK-based firm makes small, single-board computers (SBCs) initially designed to help advance computer science in schools. Its products contain most of the components found in a traditional desktop computer, but the firm squeezes them all onto a small board about the size of a deck of playing cards.

Low-cost Raspberry Pi CM4 board packs most of the functionality of a desktop computer onto this tiny device. Image courtesy of Raspberry Pi.

Since launching its first product in 2012, the company now has sold more than 56 million units, and its devices are finding use in mainstream computing applications.

Pi, as the company is often called, donates its profits to the Raspberry Pi Foundation. The foundation is an educational charity that works to empower young people to use computing technologies.

PC flips heat-management script

Upton, interviewed at January’s CES 2024 consumer technology show in Las Vegas, said: “We’re used to the idea of plastic being used as an insulator. As Raspberry Pi boards got more powerful over the years, they’ve become more thermally generating. To keep the heat under control, they’ve had to become more thermally conductive.”

Raspberry Pi CEO Eben Upton began developing his mini-computer in 2006 at the University of Cambridge in England. Image courtesy of Raspberry Pi.

As the devices — now in their fifth generation — became more powerful, Upton and his team packed their printed circuit boards with copper, all with the aim of siphoning away as much heat as possible from the central processing unit.

Pi now may have another option. It is intrigued by the possibility of overmolding its boards with thermally conductive (TC) polycarbonate (PC) to replace the previously required metal heat sinks. Upton, a Welshman who first began developing his mini-computer in 2006 at the University of Cambridge, calls the concept of TC PC “fascinating.”

“Rather than making the heat under the plastic go up,” he said, “it makes the temperatures go down” — all without interfering with the device’s Wi-Fi performance. “That’s an incredible thing to do with plastic.”

The material in question is Covestro’s Makrolon TC thermally conductive polycarbonate, which its maker says “combines heat management with the properties next-generation materials demand: Functional integration, reduced weight, and reduced RF interference for wireless connectivity.”

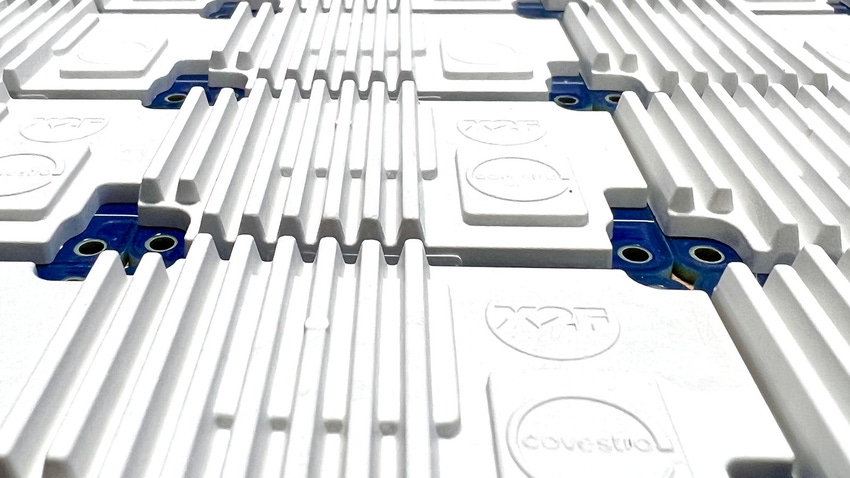

X2F’s process safely overmolds sensitive components

A Colorado molding company also is finding TC polymers to be very useful. X2F, a 6-year-old firm based in Loveland, has developed and patented a low-pressure process it calls Controlled Viscosity Molding. This low-pressure CVM process can overmold highly filled, thermally conductive polymer composites, which usually is difficult to do.

Colorado-based X2F developed its own molding machine to use its patented Controlled Viscosity Molding process. The system’s very low pressures make it safer to overmold materials onto highly sensitive electronics. Image courtesy of X2F.

CEO Mike Slowik said in an interview at CES that X2F (short for Extrude to Fill) developed its own, proprietary molding machine. It uses a pulse-packing process that precisely modulates polymer viscosity and material flow into the mold cavity at pressures some 70 to 90 percent lower than with standard injection molding. This helps to reduce molded-in stresses and damage to sensitive components during overmolding.

CVM enables easy molding of various challenging materials, from carbon-fiber-filled and glass-filled polymers to PEEK and ultrahigh-molecular-weight polyethylene (UHMWPE). Slowik also is using the Makrolon TC grades to replace cast-aluminum heat sinks with thermally conductive PC.

Covestro says the PC heat sink can be part of an in-mold assembly process that can integrate LED modules directly into a vehicle’s headlamp housing, reducing both weight and labor.

Expanding on benefits of TC polycarbonate

Brian Beyer, co-founder and CEO of Pittsburgh-based computer vision company Hellbender Inc., also in an interview at CES, expanded on the potential benefits of using TC PC in the type of electronic component design and manufacturing that his firm does.

Using a thermally conductive polycarbonate, he suggests, can dramatically lower the assembly cost and the end item cost of a product.

“There are situations,” he said, “where you don't want to use metal because you want to be RF transparent. You want to be able to use Wi-Fi, you want Bluetooth connectivity. Then the PC heat sink is going to be a great option because now we can use this as a part of our overall enclosure design.”

This also eliminates the need to use a separate antenna, which typically would be taped to a secondary plastic part of the product’s shell. “Now,” Beyer said, “the entire device can be made out of polycarbonate, and then it's a better look, fit, and finish, and more texture can be applied.”

AI vision system helps to protect cyclists

Velo AI Inc., meanwhile, is leveraging these technologies to help make cyclists safer. The Pittsburgh firm is using Hellbender’s manufacturing services and a chip from Hailo Technologies Ltd. in a Raspberry Pi computer module 4 (CM4) to create what it calls “smart tech for your bike.”

Velo’s AI-powered CoPilot light and camera attaches under the seat of a bicycle to enhance cyclists’ safety. It also can capture and store images such as the license plate numbers of vehicles in its view. Image courtesy of Velo AI Inc.

Dubbed CoPilot, it is an AI-powered bicycle light and camera that attaches under a bike seat to detect and distinguish nearby vehicles. CoPilot’s vision technology integrates with a smartphone app that can be mounted on the bike’s handlebars.

It can understand when one is about to overtake and identify an aggressive or distracted driver approaching dangerously. In such cases, it issues audible and visual alerts for the cyclist to help prevent dangerous situations and crashes, as shown in the video below.

Hailo, an Israeli maker of AI edge processors, plans to incorporate Covestro’s thermally conductive polycarbonate into some of its future products, according to DC Smalley, Hailo’s North America general manager. Its Hailo 8 chip, for instance, powers Velo’s CoPilot product.

The technology, says Velo, also has the ability to capture and store images, including, for example, license plate numbers. This could come in handy if one needs to identify the parties involved in an incident on the road.

Raspberry Pi’s Eben Upton, Hailo’s DC Smalley, and Hellbender co-founders Brian Beyer and Adela Wee discuss the technology in a series of interviews on Covestro's YouTube channel recorded at CES.

About the Author(s)

You May Also Like