Focus: Medical Plant Tour: Metal injection molding smiles

July 29, 2002

|

Ortho Organizers is a vertically integrated manufacturer of orthodontic products, offering a full line of services. One hundred percent of its dental brackets are metal injection molded. |

Manufacturing the small brackets used in its orthodontic products used to be a pretty ugly process for Ortho Organizers Inc. of San Marcos, CA. Its brackets were investment cast south of the border. Almost 90 percent of the metal used was wasted in sprues and runners. Excess material was sold to scrap dealers. The turnaround time was typically 30 days with the time wasted waiting on lines at the Mexican border. And capping things off, good parts yield ran anywhere from 30 to 60 percent. There had to be a better way.

Ortho found that better way in 1994 when it licensed metal injection molding (MIM) technology from Injectamax Corp. (Escondido, CA). MIM is a multistep process, involving feedstock preparation, molding, debinding, sintering, and, sometimes, secondary finishing procedures. Nevertheless, using manufacturing principles enlightened by lean thinking, Ortho has reduced the time wasted waiting for its parts from 30 days down to just two. That means smaller parts inventories, faster reaction to market changes, and lead time reductions.

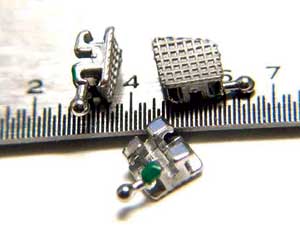

With MIM, Ortho's good parts yield now is in the 90 to 95 percent range. Materials costs have been substantially minimized as well—it can mold 10 brackets per gram and MIM sprues and runners can be recycled and reused. What's more, Ortho now is able to achieve excellent part definition on all of the complex surface geometries of its brackets, which eliminates the need for many secondaries.

|

Ortho's brackets once were investment cast. Nearly 90 percent of the material used was scrapped, good parts yield was as low as 30 percent, and turnaround times were as high as 30 days. |

Ortho has also taken on contract manufacturing for other orthodontic companies, as well as firms outside the industry.

Today, 100 percent of Ortho's entire bracket product line is done in MIM. Its entire production capacity is dedicated to serving the orthodontics marketplace, estimated to be a $700 million industry worldwide. MIM presently accounts for about $100 million of this market. Dentaurum J.P. Winkelstroeter KG (Ispringen, Germany) and Rocky Mountain Orthodontics (Denver, CO) also are orthodontics MIM molders, but our appointment's with Ortho. Let's tour.

MIM Mold Specialists

Our tour guide is Stephen Huff, director of clinical relations and new product development. He tells us that Ortho is a privately held company that is almost 30 years old. Most of top management has either been with the company, or in the business, for just as long.

Operations are spread over three buildings at Ortho's manufacturing campus in San Marcos, comprising a total of 60,000 sq ft. Our first stop is the 12,000-sq-ft engineering/moldmaking center. The company employs moldmakers and toolmakers, who handle the fixtures, EOAT, and other devices. Ortho uses Pro/E CAD software both for part and mold design, and SurfCAM via an IGES import.

It builds complete unit-frame molds for its MUD bases, about 100 every year, including the cores, cavities, and ejectors. Most of its bracket molds are 5x8 family molds with up to eight cavities. Some require artificial balancing, using a larger runner near the nozzle, for instance—a technique learned through trial and error.

|

|

Today, Ortho molds up to 9 million parts per year on its Boy injection molding machines at yields of up to 95 percent, turning around finished parts in two days. Brackets are molded in fully automated manufacturing cells running subgated, eight-cavity family molds at 30-second cycles. Each bracket costs $2 to $5. | The small brackets are removed and deposited into a press-side product handling system designed and built in-house. |

Vital Stats |

Ortho also uses three-plate molds. Materials of construction are usually A-6 and D-2. In operation, Ortho heats the A half of the mold, blowing the feedstock through the gate before it freezes in the cavities in the cooled B half.

A Mitsubishi EA8 sinker, which was a recent addition to its moldmaking equipment capacity, has all but eliminated Ortho's use of copper electrodes. The surface finishes it achieves with graphite are good enough to obviate polishing.

The Shop Is the Cell

Ortho's main MIM manufacturing floor is laid out like a lean manufacturing cell. In a lean cell, machines of different types sequentially perform their different functions for the waste-free, single-piece flow of products, and for a more flexible use of human resources.

Like many lean cells, Ortho's molding machines, mixing tanks, and furnaces are laid out in a U-shaped pattern, like a horseshoe, or, considering Ortho's product line, like teeth.

The shop floor's high ceilings and open doors keep things cool. Bright mercury lights make things easy to see. And the durable epoxy coating on the floors, the same kind used in aircraft hangars, minimizes wear and tear.

Four small-tonnage presses from Boy Machines Inc. (Exton, PA) with mold temperature controllers from Sterling (Milwaukee, WI) are laterally configured along one wall of the shop. Three of the machines—with 30, 25, and 22 tons of clamping force—are equipped with Boy's Procan machine control system. The remaining 22-tonner, an earlier model, is not.

Automated Single-piece Flow

Injectamax uses Boy machines. They were a part of Ortho's licensing requirements. Ortho is considering the purchase of a larger 50-tonner. Business is good. In fact, David Dunn, director of operations, tells us that Ortho has exceeded the orthodontics industry's growth since its inception.

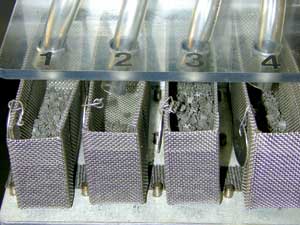

The three newer machines are equipped with robotic sprue pickers. These are the bracket molding presses, Ortho's main MIM product line. Green parts are retrieved from the subgated molds and are immediately placed into a press-side device that segregates the brackets by cavity. Scrap is carried over to a granulator from AEC/Nelmor Inc. (Woodale, IL) for reuse.

Ortho uses heated nozzles for its eight-cavity molds. To improve flow through small, sub-millimeter gates, the feedstocks are run at a temperature just below the breakdown temperature of the polymer/paraffin-wax binder systems.

Huff says the material freezes off at the gate all the time, thanks to cooling the mold's B half. The company makes its own feedstocks. It also purchases Advamet feedstocks from Advanced Metalworking Practices Inc. (Carmel, IN).

A Molded Competitive Edge

After they are debound and sintered, the brackets are polished in a room off the floor. The micro-etched bonding surfaces of Ortho's brackets (the base where the brackets adhere to the surface of the tooth) are micromolded in. Polishing is the only secondary operation required for brackets.

In addition to brackets, Ortho manufactures a full line of orthodontic products and appliances, including a precision molded intraoral bite corrector that provides gentle continuous force to teeth by means of two joined cylinders. It's designed for function, not looks. That's why they've nicknamed it "The Terminator" in the shop.

The third building on the campus manufactures shape memory wire out of a super-elastic nickel titanium alloy. The wire is used to fashion coil springs that are used in Ortho's orthodontic appliances. Once heated in belt furnaces and bent into shape, the wires remember their shape.

Through field reps and its B2B telemarketing department, Ortho sells to dealers in 75 countries. The competitive part costs and quality it has been able to achieve by using MIM have allowed Ortho to penetrate developing world markets. About 20 percent of its business is in Latin America.

In closing, Huff says, "With MIM, 99 percent of our manufacturing cost is in our capital equipment, not labor. That's one reason why MIM is staying afloat in the U.S. MIM is the solution worldwide."

|

|

Molds for its brackets, Ortho's largest-volume MIM application, are typically eight-cavity family molds. Only the B half of the mold is cooled. Ortho's Huff says material freezes off at the gates every time. |

|

|

Ortho has four furnaces for thermal debinding and sintering, two of which were built in-house. It had only two furnaces two years ago. | Ortho designs and builds all of its molds, about 100 per year. This North-South Machinery Mitsubishi EA8 sinker can run 24/7. Its programmable accuracy has nearly eliminated Ortho's use of copper electrodes. |

|

|

The product handling system segregates the green brackets by cavity, improving flow and traceability. | Chemical solvent debinding for some of its feedstocks is performed in this environmentally friendly, closed loop unit. |

Contact information |

You May Also Like