The Popp Group, a project manufacturer based in Forchheim and specialized in the design, engineering and production of everything from industrial components to stage sets, has successfully added 3D printing to its repertoire of production technologies. Using an X X400 3D printer from German RepRap, the Group recently produced 3D printed door hinges for a customer in the medical technology sector. The customer was seeking to reduce manufacturing costs for medical cabinets as part of a cost-down procedure.

June 30, 2015

The Popp Group, a project manufacturer based in Forchheim and specialized in the design, engineering and production of everything from industrial components to stage sets, has successfully added 3D printing to its repertoire of production technologies. Using an X X400 3D printer from German RepRap, the Group recently produced 3D printed door hinges for a customer in the medical technology sector. The customer was seeking to reduce manufacturing costs for medical cabinets as part of a cost-down procedure.

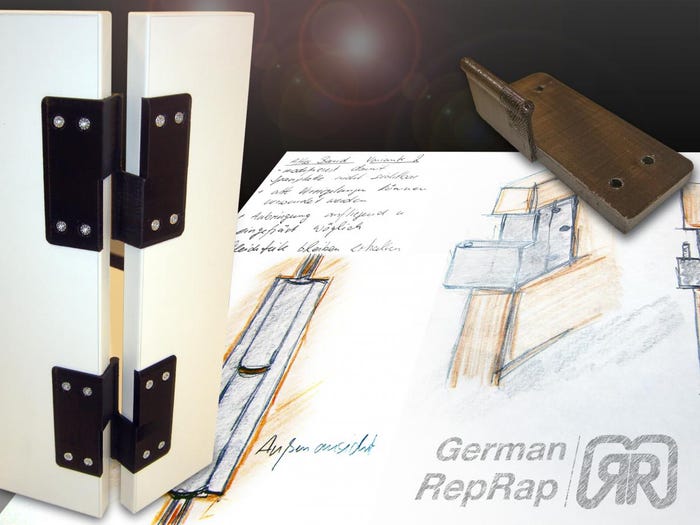

“Our aim was to reduce production costs by producing an adjustable hinge for which many identical parts can be used,” explained Holger Ried, technical product designer responsible for the project at the Popp Group. “A large amount of money can be saved already in the development phase.”  The Popp Group was established over 100 years ago as a woodworking company, but quickly moved into the then emergent furniture industry in the early twentieth century. It can therefore draw on a rich store of experience with manufacturing furniture parts. Prior to determining the final design of the hinges, a great many hand drawings were made. These drafts were then modeled in 3D with the help of SolidWorks, in order to prepare for later printing in PLA bioplastic.

The Popp Group was established over 100 years ago as a woodworking company, but quickly moved into the then emergent furniture industry in the early twentieth century. It can therefore draw on a rich store of experience with manufacturing furniture parts. Prior to determining the final design of the hinges, a great many hand drawings were made. These drafts were then modeled in 3D with the help of SolidWorks, in order to prepare for later printing in PLA bioplastic.

The Popp Group printed several function models at the same time, both for test purposes and which could serve as prototypes for the customer and presented as display models. German RepRap’s X400 3D printer series is designed for large format industrial 3D printing and the printing area of 40 x 40 cm (15,7 x 15,7 inches) enabled several prototypes to be printed at the same time.

“Compared to 3D printing, laser sintering or CNC cutting is very expensive,” said Holger Ried. “We had also tried printing in plaster, but stopped using this method on account of the relatively high maintenance costs of the printer. “

The flexibility of 3D printing technology makes it possible to implement any necessary modifications almost immediately, so that new models can be presented to the customer in the shortest possible time. Previously, it took often a week before a prototype could be supplied, only then to discover that the design once again needed to be modified. With 3D printing, says Popp Group, the time gain is incredible: depending on the model, the time required for prototype production today has fallen from one week to eight hours. The customers also appreciate the new possibility of quickly being able to hold prototypes in their hands.

“I had always been an advocate of 3D printing,” Ried recalled. The X400 from German RepRap soon became the preferred solution due to its price-performance ratio. The X400 has now been running almost continuously for at least six months.

German RepRap (Feldkirchen, Germany) is known for its ruggedized, industrial 3D printers. The company develops and sells 3D printing solutions based on the RepRap technology (Fused Filament Fabrication) as well as 3D scanners, filament, software and accessories. With the X400, German RepRap was the first Germany to release a large-capacity 3D printer for professional users; the company has now also expanded the line with an even larger industrial model, the X1000.

About the Author(s)

You May Also Like