ABS, PLA grades debut for 3D printing

Optimized for FDM additive prototyping and manufacturing processes.

March 1, 2017

Spain’s Elix Polymers is developing additional specialty grades of ABS optimized for 3D printing, after the considerable interest shown in its initial offering at K 2016 in Düsseldorf last October.

“We now have a better idea of the high potential growth rates of the 3D printing market after the show,” says Fabian Herter, Industry Manager Automotive. “We think Elix can be an important player in this exciting market. 3D printing fits well within our strategy of focusing on specialty businesses through tailor-made products and services.”

|

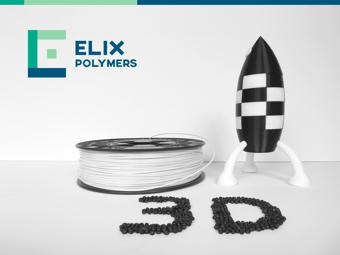

Elix Polymers expands its portfolio of ABS grades for 3D printing. |

After conducting a detailed analysis of specific customer needs, Elix can offer 3D printing grades that have been optimized to meet those needs. Some new grades have already been validated at filament producers, 3D printer manufacturers, and final part manufacturers that use fused filament fabrication (FFF), more commonly known as FDM (fused deposition modeling). This technology has a wide range of applications in sectors such as the automotive sector, healthcare, aerospace, E&E, consumer products, and toys.

To date, Elix has optimized five ABS grades for 3D printing, each fulfilling different customer requirements. They all show improved printing performance, low warpage, dimensional precision, and high resolution. The portfolio includes a general purpose grade (Elix ABS-3D GP); a grade that complies with Commission Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food and with biocompatibility standards (ISO 10993-1 and USP class VI) for food contact and medical applications (Elix ABS-3D FC); a high impact grade (Elix ABS-3D HI); a grade with improved interlayer adhesion for complex parts (Elix ABS-3D LA); and an ABS reinforced with natural fibers that creates a wood-like appearance when used on special 3D printers (Elix ABS-3D NF). All grades are available in natural color or precolored in various shades.

Elix plans on supervising the complete 3D printing value chain. It is therefore already cooperating with several leading printer producers and 3D software providers. “The objective is to not only develop new formulations, but also identify the right partners and create a database with validated filament producers,” states Antonio Prunera, Head of Quality Business Development.

Elix offers technical support, including recommendations about correct processing set-ups: extruder screw design, the drive system, and the spool system. The idea is to obtain a filament that has the best quality properties within typical thicknesses of between 1.75 mm and 2.85 mm and to validate that the material meets the requirements of the final application. Elix has defined its own demanding material tests to evaluate final filament quality.

In other 3D printing material developments, NatureWorks has introduced Ingeo 3D870, a new cost-effective grade of polylactic acid (PLA) for 3D filament manufacturers looking for “innovative means of expanding sales into the industrial prototyping and additive manufacturing market.” Mechanical properties are reportedly similar or superior to ABS.

Feedback from filament manufacturers that have trialed the product cites the ease of processing Ingeo 3D870 and printer manufacturers praise its printability; both have uniformly said there are no materials available today that provide this combination of superior filament processing, printability, and printed part performance characteristics.

NatureWorks developed Ingeo 3D870 to meet the growing demand by industrial companies for a material that combines the properties of ABS and the printability of Ingeo PLA. Ingeo 3D870 complies with chemical inventory listings in key markets in North America, Asia, and Europe, which expands sales opportunities for filament manufacturers. Parts produced with the formulation exceed ABS 3D parts in impact strength and, with post-print annealing, rival ABS heat resistance.

Ingeo General Purpose PLA is good for many applications, including 3D printing, but 3D850 and 3D870 have been designed specifically for 3D printing. Building on reliable, easy printability, these two grades offer good UV color lightfastness, low yellow index, and can be crystallized to realize additional heat and impact properties. 3D870 was designed specifically for the impact strength required in industrial applications.

|

PLA grades for 3D printing exhibit superior impact strength compared to ABS, while heat resistance can be improved through annealing. |

About the Author(s)

You May Also Like