HP drives distributed design, manufacturing and supply chain transformation with Jabil and Forecast 3D

HP Multi Jet Fusion customers and partners represent critical links in a new value chain that’s rewriting the rules of design, production and delivery, said Stephen Nigro, President of 3D Printing at HP (Palo Alto, CA).

April 30, 2018

HP (Palo Alto, CA) announced new industry agreements with Jabil (St. Petersburg, FL) and Forecast 3D (Carlsbad, CA) at the RAPID + TCT conference last week in Forth Worth, TX. The agreements are expected to drive the future of distributed design, manufacturing and digital supply chains leveraging the power of HP Multi Jet Fusion 3D-printing technology, said the company.

As the global economy enters what many call the fourth industrial revolution, technologies such as 3D printing are enabling an array of new business opportunities such as distributed design and manufacturing, supply chain services and increasingly localized production.

|

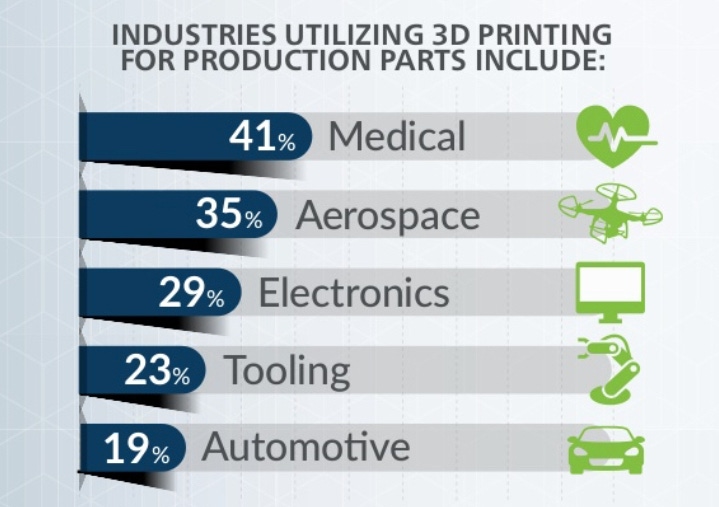

Image taken from an infographic published by Jabil. |

“From multinational design engineering and manufacturing to localized production, industry leaders such as Jabil and Forecast 3D are demonstrating 3D printing’s expanding role in the digital transformation of the $12 trillion global manufacturing economy,” said Stephen Nigro, President of 3D Printing, HP Inc. “HP Multi Jet Fusion customers and partners represent critical links in a new value chain that’s rewriting the rules of design, production and delivery, ultimately ushering in a new era of digital manufacturing.”

Also at RAPID + TCT, Jabil announced its Additive Manufacturing Network to drive greater manufacturing speed and agility while helping customers improve how they design, make and deliver products. “Jabil’s digital thread fuels a growing footprint of 3D printers and additive manufacturing capabilities to benefit customers through localized production, consolidated supply chains, reduced costs and faster time-to-market,” said John Dulchinos, Vice President of Digital Manufacturing for Jabil. “Our new Jabil Additive Manufacturing Network is the connective tissue that scales globally to integrate every printer, facility and work order across our enterprise and crystallize our vision of truly distributed manufacturing.”

Over the past year, Jabil has steadily increased its 3D-printing capacity with more than 100 3D printers now in operation at facilities in the United States, China, Hungary, Mexico, Singapore and Spain. A variety of 3D-printing machines have been installed for high-speed sintering, fused filament fabrication, polymer and metal laser sintering and other processes to address emerging customer needs in the footwear, industrial machines, transportation, aerospace and healthcare industries. Jabil’s distributed manufacturing strategy is anchored by this growing ecosystem of 3D printers, which includes a dozen production-ready HP Jet Fusion 4200 3D printers, following the recent installation of six HP Jet Fusion 4210 printers at its Singapore facility.

Dulchinos commented, “HP Multi Jet Fusion gives us the foundational 3D-printing platform we need to deliver truly industrial-grade production applications for our globally distributed customers. Our aim is to harmonize the multiple regions, technologies, materials and manufacturing workflows of the fourth industrial revolution, and HP is an important partner in that effort.”

Forecast 3D, one of the oldest and largest privately held 3D-printing companies in the United States, is adding six new HP Jet Fusion 4210 solutions to expand its fleet to 18 systems in response to increasing customer demand. Forecast 3D plans to produce several million end-use parts on HP’s 3D printers in the coming year, delivering commercial-grade applications for clients in multiple industries including the medical, consumer goods, aerospace, defense and auto sectors.

“Our customers across all industries have spoken, and they are looking for more of the speed, quality and cost benefits for production applications unleashed by HP Multi Jet Fusion,” said Corey Weber, CEO of Forecast 3D. “We are investing in this important 3D-printing technology platform as we scale up to meet rising demand from international and domestic clients seeking to reinvent their product lifecycle.”

HP is committed to democratizing 3D design and manufacturing and recently expanded its portfolio with the introduction of the Jet Fusion 300/500 series, the world’s first 3D printers to deliver engineering-grade, functional parts in full color, black or white in a fraction of the time of other solutions, stated HP in its release.

About the Author(s)

You May Also Like