Open source 3D printing means freedom to improve technology

Aleph Objects believes in open source 3D printing. In fact, the company was born to build open source and its philosophy of "Libre Hardware" is built into everything the company creates. "We exist for the freedom of our users and the benefits that brings," said Harris Kenny, communications manager for Aleph Objects, a Loveland, CO-based maker of the LulzBot 3D desktop printer.

June 26, 2014

Aleph Objects believes in open source 3D printing. In fact, the company was born to build open source and its philosophy of "Libre Hardware" is built into everything the company creates. "We exist for the freedom of our users and the benefits that brings," said Harris Kenny, communications manager for Aleph Objects, a Loveland, CO-based maker of the LulzBot 3D desktop printer.

The company promises in its information that "when you buy a LulzBot, your hardware and software will never be locked down and become obsolete or require licensed upgrades as the industry advances." Kenny told PlasticsToday that the open source community developed around LulzBot provides a forum for new ideas and improvements - something that Aleph Objects encourages.

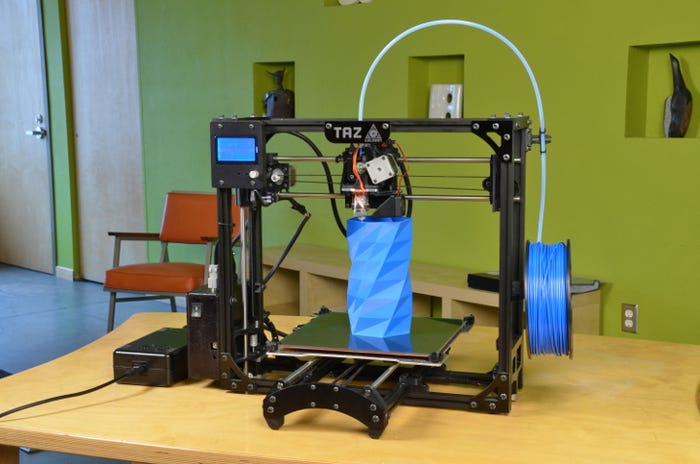

The LulzBot TAZ has a print envelope of 11.7" x 10.8" x 9.8", which the company claims is the largest of all assembled desktop 3D printers under $2,500. The heated bed allows users to print large objects more easily. The TAZ also offers faster printing and finer resolution that competing desktop printers. The LulzBot comes standard with a 0.35mm print nozzle, with interchangeable options available including a .75mm nozzle that can print a layer height of 750 microns.

The LulzBot TAZ has a print envelope of 11.7" x 10.8" x 9.8", which the company claims is the largest of all assembled desktop 3D printers under $2,500. The heated bed allows users to print large objects more easily. The TAZ also offers faster printing and finer resolution that competing desktop printers. The LulzBot comes standard with a 0.35mm print nozzle, with interchangeable options available including a .75mm nozzle that can print a layer height of 750 microns.

Users can customize the LulzBot to suit their needs because the company's "open build" allows users to modify the machine to print in a variety of materials. "We print with a lot of different materials, including ABS, PLA, PVA, high-impact polystyrene, wood and stone filaments and more," Kenny said. "In fact, material developers can send us a sample of their filament and we'll try it and see how it works. If a company comes up with a great material, we'll develop a new print head for it. With add-ons, you can print with nylon, rubber-like materials and more."

About the Author(s)

You May Also Like