Sumitomo Chemical Completes Construction of Acrylic Chemical Recycling Pilot Plant

Samples of chemically recycled methyl methacrylate or MMA monomer and acrylic resin made from the monomer will become available this spring.

December 28, 2022

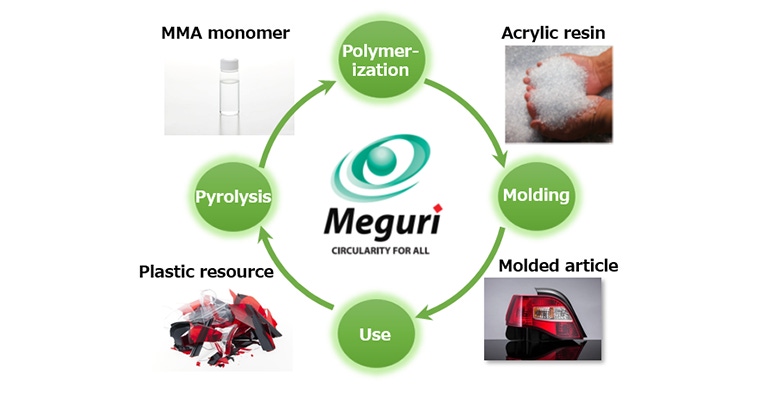

Japan’s Sumitomo Chemical has constructed a new pilot facility for chemical recycling of acrylic resin (polymethyl methacrylate; PMMA) at its Ehime Works in Niihama City, Japan. Samples of chemically recycled methyl methacrylate or MMA monomer produced in this facility and acrylic resin made from the monomer will become available in spring of 2023. The company will accelerate the development of a circular system for acrylic resin that integrates all steps — from collection of used acrylic resin to recycling of the collected resin into a monomer material to use of the material as products.

Acrylic resins, which possess the highest level of transparency among plastics as well as superior weatherability and processability, are used in a range of applications, such as automobile tail lamps, home appliances, water tanks, liquid crystal displays (LCDs), and protective partition panels to reduce the spread of potentially infective droplets. Meanwhile, as plastics are made from fossil resources, there is an urgent need to reduce greenhouse-gas (GHG) emissions generated across the entire process, from production to disposal of plastics, as well as to promote the recycling of used plastics as resources.

|

The pilot facility for chemical recycling of acrylic resin is installed at Sumitomo Chemical's Ehime Works in Niihama City, Japan. |

Sumitomo Chemical teamed up with Japan Steel Works (JSW) to develop a technology for pyrolyzing acrylic resin and recycling it with high efficiency into MMA monomer, which is a raw material for acrylic resin. The new pilot facility Sumitomo Chemical has built at its Ehime Works is equipped with a JSW twin-screw extruder. Sumitomo Chemical will validate the technology to recycle acrylic resin at a high-quality level and work on scaling the production process. The recycled MMA monomer will have the same quality as virgin MMA monomer but it will generate at least 60% fewer GHG emissions over its entire life cycle, according to Sumitomo Chemical.

The company has also set out to build a circular system for acrylic resin. It will collect acrylic plastic scraps and used acrylic resin from long-time business partner Nippura Co. Ltd. as well as from major home appliance manufacturers, while developing a customer base for acrylic resin made from the recycled MMA monomer. Going forward, Sumitomo Chemical will step up collaboration with partners in other industries on collection, recycling, and markets to accelerate the development of a circular system for acrylic resin.

In September 2022, Sumitomo Chemical launched the Meguri brand for plastic products made with recycling technology as part of its effort to contribute to building a circular economy. The Meguri brand is put on products that meet certain criteria, such as GHG emissions, that the company has established. The chemically recycled MMA monomer produced in the newly constructed pilot facility and acrylic resin made from the monomer will be the first Meguri brand products.

In the future, acrylic resins obtained using recycling technology will be sold as Sumipex Meguri. In addition, acrylic resin sheets made via material recycling technology, handled by wholly owned subsidiary Sumika Acryl Co. Ltd., will also be sold under the Meguri brand. Sumika Acryl Sheet Meguri is scheduled to be launched in January 2023.

You May Also Like