What’s Happening in Advanced Recycling Now

Sorting through the plastic packaging recycling options of dissolution, depolymerization, pyrolysis, and gasification.

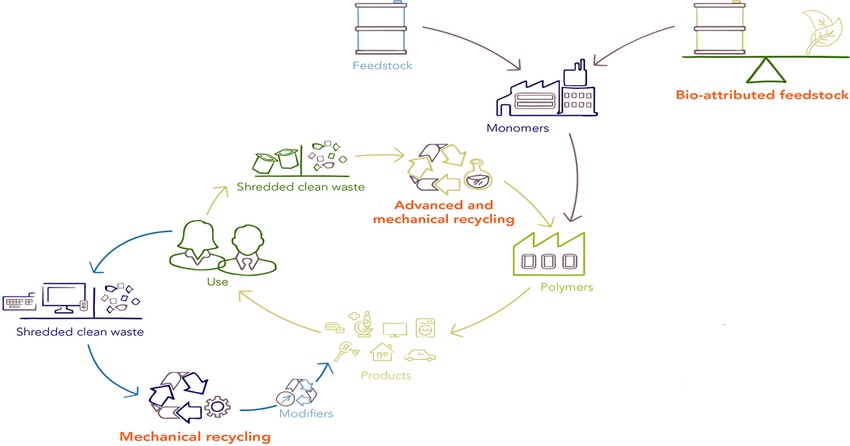

Traditional mechanical recycling as it is today presents significant limitations including degradation of valuable polymers leading to “down cycling” and the added necessity of having to supplement post-consumer sources for reuse with virgin material.

On the other hand, traditional mechanical recycling has significant advantages such as low energy requirements and a mature technology, with established understanding and process acceptance within the recycling industry.

In recent years, demand for recycling solutions has increased. The plastics industry is becoming extensively involved in finding end-of-life solutions for plastic waste — launching a new era in viability and in investments in new plastic recycling technologies.

New and innovative recycling technologies enable us to capture a broader spectrum of plastic waste, processing materials at higher contamination levels and, in some cases, eliminating the need for complex and expensive sorting steps, which are often cited as a reason for low recycling rates.

True to the nature of innovation, creativity combined with groundbreaking science has resulted in a variety of new technologies. Working together, each part plays a critical role and allows us to build the zero waste future we greatly need: making the commercialization of advanced recycling technologies within reach.

Dissolving plastic: Dissolution.

The dissolution method of advanced recycling takes plastic waste in its solid form and dissolves it in a solvent. Once dissolved, the process can mechanically and chemically separate contaminants and additives, before finally separating the original polymer from the solvent. The end-product then becomes a cleaned polymer that may be used as new raw material resin again. Polystyvert Inc. uses this process to recycle polystyrene. It is a novel approach to a polymer that has historically been deemed challenging for recycling.

Polymeric breakdown: Depolymerization

Depolymerization technology is poised to be a game-changer in the way we recycle. This technology provides us the ability to “un-zip” a polymer chain and then break it down into the individual building-block molecules for unparalleled separation, purification, and recovery of plastic materials. The resulting product is a plastic raw material (monomer) that is nearly identical to material sourced from traditional fossil fuels.

This means the depolymerized material can then be used for food contact and even medical applications. In other words, no down-cycling! Additionally, the depolymerization process does not degrade the polymer/monomer material, meaning that this process can be repeated on the same material an infinite number of times. Future generations ten years from now will be able to enjoy the benefits of a well-insulated coffee cup made using the same molecules in your used coffee cup today!

INEOS Styrolution is one company embracing depolymerization. Cooperating with the innovative technology company, Agilyx, the two have begun engineering a new facility located just south of Chicago, IL, which will eventually recycle up to 100 tons of polystyrene material per day.

Collaboration catalyst: Pyrolysis.

Pyrolysis uses a thermal cracking process to convert plastic waste to an oil, which is often further purified and then used as feedstock in the production of base chemicals- for example, ethylene which is used for polymer production. The Pyrolysis method has sparked industry collaboration due to the process producing base chemical products that can be developed and used across multiple polymer segments. Even the by-products of pyrolysis are finding purpose as seen in the collaboration between Ineos Styrolution and GreenMantra Technologies. GreenMantra’s unique approach converts polystyrene waste directly into marketable products. Ineos Stryolution is working to purify GreenMantra’s byproduct stream to recover styrene monomer for polymerization into recycled polystyrene resin.

Contamination solution: Gasification.

Wondering what to do when waste is too contaminated to process using any of the above technologies? Gasification! This recycling method enables processing of mixed plastic waste alongside domestic and bio-waste. This technology heats materials to high temperatures in the absence of oxygen (i.e. not burning or incinerating the material), creating syngas. Syngas is then used as a carbon source to produce base chemicals such as methanol and ethanol, beginning the value chain to numerous end-products. Enerkem is a gasification technology company that is leading the way to commercial scale. Enerkem’s technology has been deployed at Edmonton, Canada’s Waste to Biofuels and Chemicals site, supporting the city’s goal of 90% landfill diversion.

The University of Florida is conducting related research and development in this area as well (see Is plasma gasification the solution for plastics and all waste?, published August 2019).

What’s this all mean?

Plastics are highly engineered materials, providing unparalleled value to our society. From inception, plastics have always been a pioneering material and it is, of course, quite fitting that the technologies now being used to recover these materials are just as innovative and impactful. As our attitudes and attention towards the earth’s climate and environment continue to evolve, so must our infrastructures and behaviors change with them.

Cassie Bradley is INEOS Styrolution’s Sustainability and Circular Economy Commercial Manager.

About the Author(s)

You May Also Like