Aurora Plastics Inc. (Streetsboro, OH), a manufacturer of rigid and foam PVC, has introduced a highly weatherable PVC/acrylic alloy capstock designed to withstand the effects of long-term weathering, even in dark colors. The new product is suited for a variety of demanding applications including outdoor trim, windows, decks, siding fencing and railings.

March 12, 2015

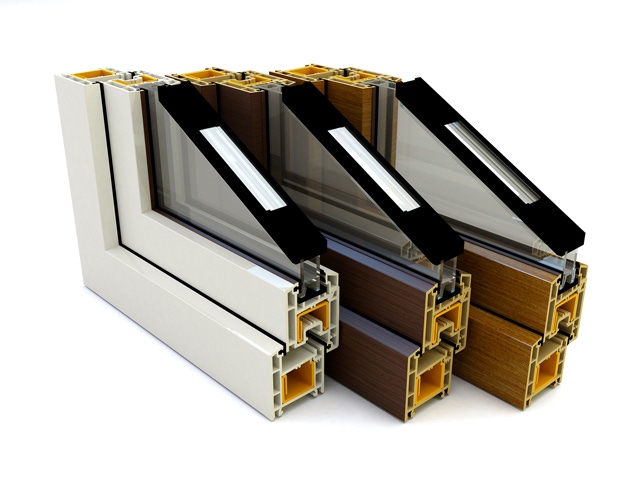

Aurora Plastics Inc. (Streetsboro, OH), a manufacturer of rigid and foam PVC, has introduced a highly weatherable PVC/acrylic alloy capstock designed to withstand the effects of long-term weathering, even in dark colors. The new product is suited for a variety of demanding applications including outdoor trim, windows, decks, siding fencing and railings.

For processors working on building and construction applications, the material offers processing characteristics that translate into a more consistent coating, less scrap, a faster startup time and a wider processing window, according to the company. Aurora Plastics will debut the material at NPE2015, booth S-15061.

For processors working on building and construction applications, the material offers processing characteristics that translate into a more consistent coating, less scrap, a faster startup time and a wider processing window, according to the company. Aurora Plastics will debut the material at NPE2015, booth S-15061.

"We identified a need in the market for a more cost-competitive, long-lasting solution," said Matthew Kuwatch, Vice President, Marketing and Business Development. "There are currently many options available, but most of them do not offer the same level of long-term weatherability and resistance to water whitening, especially in the darker colors. From a processing perspective, our product is easier to handle, resulting in significant bottom-line benefits for our customers. We believe we have created the ideal solution by combining the proven processing advantages of PVC with the added UV resistance and weatherability of acrylic," said Kuwatch.

Designed for use with the company's cost-effective interior-grade RPVC or foam RPVC compounds as substrates, the new pelletized PVC/acrylic alloy capstock compound can be applied thinner than standard RPVC capstock to create an efficient, high-performance outer layer. The compound colors easily to match customer needs and can also be streaked to replicate wood or embossed, said Aurora Plastics' information.

Additionally, Aurora Plastics has raised the bar with its new low-density cellular PVC foam. Aurora Plastics offers a product line available in the 0.35 to 0.80 density range, which includes some of the lowest density cellular foams in the industry. The end result is a highly lightweight, yet durable, material for an array of interior decorative applications. This will also be showcased at NPE2015.

"Aurora Plastics continues to focus on discovering unmet needs and creating solutions for our customers," Kuwatch said.

Aurora Plastics has two of the newest ISO 9001:2008-certified production facilities, both located in Streetsboro, OH.

About the Author(s)

You May Also Like