CY Plastics leverages automation, legacy of innovation to reshore molding jobs from China

When I visited the Rochester area in upstate New York a number of years ago to do some plant tours, I remember driving past the sprawling empty buildings and expansive parking lots that used to be home to Kodak and Xerox, two Fortune 100 companies that put Rochester on the map technologically. While those two companies are no longer part of the manufacturing landscape in the Rochester area, they left behind a legacy that includes a growing, successful plastics industry.

June 22, 2015

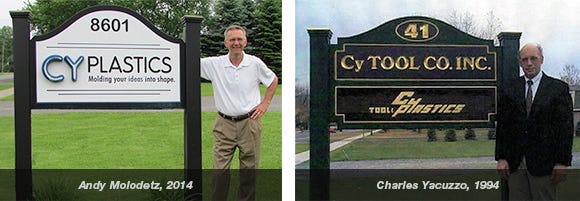

About nine years ago, Andy Molodetz moved with his family back to the upstate New York area, where they were from originally. Molodetz had spent the early part of his career working for various manufacturers, so manufacturing was in his blood. As Molodetz looked around the area for his next career move, he met Charles Yacuzzo, the owner of CyTool Company Inc., who was ready to retire.

"This looked like a business I could get my arms around," Molodetz told PlasticsToday.

Molodetz renamed the company CY Plastics (Honeoye, NY) to reflect the company's expansion into both injection molding and blowmolding. Currently, CY Plastics has 17 injection molding machines and two blowmolding machines, and it employs 55 people in its 38,000-square-foot facility, which includes 12,500 square feet of warehouse space to support growing demand for managed inventory. "Plastics has remained a core competency in this area and has come back full strength," he said of the company's success.

|

Signs of the times: Andy Molodetz bought CyTool from Charles Yacuzzo and renamed it CY Plastics. |

CY Plastics is also reaping the benefits of the reshoring phenomenon that is occurring. One customer has contracted with CY Plastics to produce injection molded components, moving the work from China and from current U.S. suppliers to consolidate its supplier base and shorten the supply chain. CY Plastics will take over production of more than 15 engineered components in a Kanban operation for the customer. To accommodate the additional molding, CY Plastics is purchasing a dedicated injection molding machine for the project.

"For a while, we saw the ‘lemming effect,' as companies chased low-cost labor in China, but that labor isn't as cheap as it used to be," said Molodetz, explaining the customer's move. "Also, there are issues with supply-chain management when you're bringing product in from the other side of the world. We do a lot of Kanban for our customers. They can order parts in the morning and we ship them in the afternoon. They realized there are a lot of hidden costs when you source from that far away, as well, such as having a lot of inventory to cover order requirements if shipping from China is delayed. Product changes happen so much faster than they used to, so a large amount of inventory can mean you end up with a warehouse full of obsolete inventory."

While quality from Chinese suppliers has gotten better, Molodetz noted that it's still an issue. "All of that has contributed to customers rethinking where their suppliers are located," he said.

Automation plays a big role in helping CY Plastics be competitive with offshore suppliers, Molodetz added. "A lot of this project's components are sonic welded. We have robots that remove the parts from the press and place them into the welder, then move them to a conveyor," he said. "With automation, we've eliminated any competitive advantage a low-cost-labor country has to offer."

That said, CY Plastics' customer continues to source about 35% of its components from China. "But they don't want to," said Molodetz. "The gauntlet has been thrown down—if we can get our cost [down] and [create] value in other respects, they will put pull more work out of China."

The real value, believes Molodetz, is that, as a supplier, he gets to know his customers personally. And his customers get to know CY Plastics. "It's a tremendous value as a supplier to know my customer and to be located near them in the Rochester area," he commented.

Molodetz is excited to be a part of the molding community in upstate New York, where the plastics industry is growing, and taking advantage of the personnel and technology advancements started by the Fortune 100 companies that laid the groundwork for the growth of the plastics industry in that region.

"I had no idea how much fun this business would be, or how much hard work it would take to get here, but I don't regret it," said Molodetz.

About the Author(s)

You May Also Like