Dimensionally precise parts are delivered in and outside of the autoclave at temperatures up to 180° C.

March 11, 2021

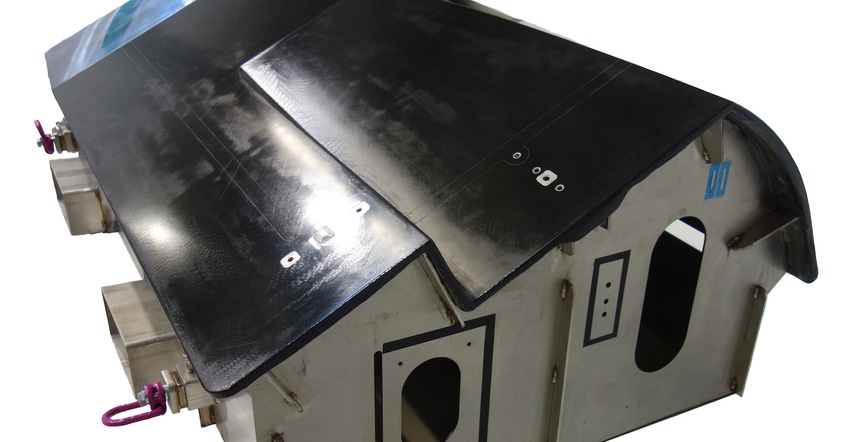

Decision SA, part of European composites consortium Carboman Group and a specialist in the development, prototyping, and production of large composite structures, has developed a direct mold tooling technology for aerospace. Decision’s latest tooling solution provides OEMs and manufacturers with short lead times highly stable direct molds for series production both in and outside of the autoclave at temperatures up to 180° C.

Decision and Carboman recently delivered the first customer molds using the new technology for the series production of a Class 3 fairing for a leading European aerospace OEM. Decision has immediate availability and capacity for similar tooling projects with lead times currently as short as six to eight weeks.

With no traditional plug or mold pattern required, Decision’s direct mold process starts with the group’s engineers selecting a material combination for the tool surface and support structure that will provide the optimal match between the mold’s coefficient of thermal expansion (CTE) and the composite part to be processed. The CNC-machined composite face sheet is supported by a stress-relieved metallic or composite backing structure before final post curing and machining is completed. The principal benefit of this approach, aside from removing the need for costly and time-consuming plug production, is the production accuracy delivered by the closely matched CTE of the mold tool and the finished composite part.

The autoclaved composite tool surface is dimensionally stable up to processing temperatures of 180°C and can also be configured with additional metallic inserts or fixtures, if required.

Produced in an EN 9100:2018 controlled production environment, and with CMM checks before and after machining, the new direct composite tools have dimensional tolerances of +/-0.2 mm. The available tooling dimensional envelope is currently defined by Decision’s 2,200 x 6,000 mm autoclave.

“With our new direct tooling technology, we are able to combine the highest technical standards in dimensional accuracy and thermal stability with extremely short lead times. Decision and Carboman Groups’ combined mission has always been to develop the construction methods for tomorrow’s composite structures, and we believe that this tooling solution will allow our customers to accelerate the implementation of the next generation of high-performance carbon-fibre aerostructures and components,” said Grégoire Metz, Managing Director, Decision SA.

About the Author(s)

You May Also Like