Tenax non-crimp fabrics and braided fibers from Teijin have been qualified for Airbus for conversion using resin transfer molding.

August 24, 2020

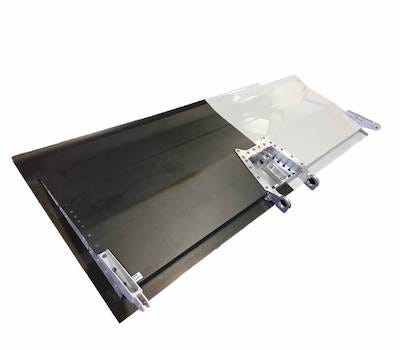

Teijin Limited announced today that it has qualified its carbon fiber materials Tenax Dry Reinforcements (DR) for the Airbus A320neo wing spoilers using a resin transfer molding (RTM) process developed by Spirit AeroSystems Inc, one of the world's leading manufacturers of aircraft structural components. The highly automated RTM solution incorporates Tenax Dry Reinforcements Non-Crimp Fabrics (DRNF) and Tenax Braided Fibers (DRBF) to form skins and stiffeners while maintaining existing product interfaces, allowing direct replacement of the all final spoiler components.

Tenax DRNF and Tenax DRBF have been developed for resin infusion and resin transfer molding processes which can offer higher productivity and component integration than conventional autoclave molding. Tenax DRNF are created of bundled carbon fiber filaments being spread out in one direction in multiple layers with different directions, depending on the final component`s structural requirements.

|

The Airbus A320neo wing spoilers are molded using the RTM process. Image: Teijin |

The fabrics have excellent fiber orientation which results in better mechanical properties than conventional woven fabric and reaches properties equivalent to aerospace grade thermosetting unidirectional prepreg. Tenax DRBF are applied within the spoiler component structure to act as cavity fillers, these materials have been qualified individually by Airbus specifically for this application.

The combination of the Tenax DRNF and Tenax DRBF achieve the Spirit AeroSystems criteria for aircraft component production such as effective process ability, productivity, and cost efficiency. A320neo spoiler components will be manufactured within a new high-volume production facility in Spirit AeroSystems, Prestwick, Scotland.

As one strategic focus of its medium-term management plan for 2020-2022. Teijin is accelerating its development of mid- to downstream applications for aircraft, such as cost-effective carbon fibers with higher-tenacity and higher-tensile modulus, intermediate materials including Tenax Dry Reinforcement carbon fiber materials, carbon fiber thermoplastic unidirectional pre-impregnated tape (Tenax TPUD), carbon fiber thermoplastic consolidated laminate (Tenax TPCL) and thermoset prepreg. Going forward, Teijin intends to further strengthen its carbon fiber and its intermediate material business as a leading solution provider for aircraft applications, targeting annual sales in this field in excess of $900 million by around 2030.

About the Author(s)

You May Also Like