Biomass Polycarbonate in Pipeline via Japanese Partnership

Mitsui Chemicals will provide biomass feedstock to Mitsubishi Gas Chemical for polycarbonate production.

February 23, 2023

Mitsui Chemicals Inc. and Mitsubishi Gas Chemical Co. Inc. (MGC) have launched initiatives to manufacture and market biomass polycarbonate (PC) as part of the companies’ efforts to achieve carbon neutrality by 2050. Mitsui Chemicals will provide biomass-derived bisphenol A (BPA), which is scheduled to be developed under its BePlayer brand, and MGC will use this as a monomer feedstock in the manufacture of its PC Iupilon.

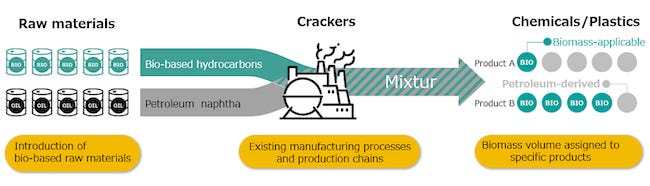

In December 2021, Mitsui Chemicals was the first company in Japan to allocate derivatives and products (made with bio-based hydrocarbons as a raw material) using the mass balance method based on the ISCC Plus certification system. It is currently selling biomass-based chemicals and resins, including epoxy resin and α-methylstyrene. Mitsui has also begun to offer products in the biomass phenol chain, where it has traditionally been difficult to prepare biomass aromatic compounds taken directly from plant-derived raw materials. The company aims to have all seven products BPA certified and on the market by March 2024, when it will start providing biomass BPA to MGC.

|

Mitsui Chemicals is working to make its entire polycarbonate framework either CO2- or plant-derived. |

MGC will purchase the ISCC Plus–certified biomass BPA from Mitsui Chemicals for the first time in Japan and will begin efforts to produce biomass PC at its Kashima plant using the interface polymerization method. MGC will utilize Kashima Polymer’s compounding capability and MGC Filsheet’s processing facilities — both companies are part of the MGC group — for rigid, highly transparent sheet and film products for molding to add functionality to biomass PC. Furthermore, MGC is building an integrated supply chain for biomass PC products by marketing these products through the global sales networks of Mitsubishi Engineering-Plastics and Mitsubishi Gas Chemical Trading.

MGC's Kashima plant and the MGC Group companies mentioned above are aiming to obtain ISCC Plus certification by the end of this year. Up to now it has been challenging to procure biomass PC products for various fields, including automotive, electrical and electronics, optics, and semiconductors. The ISCC Plus certification will allow for these products to be supplied widely through the mass balance method. In addition, MGC is planning to use circular carbon methanol together with biomass BPA to make the entire PC framework derived from either CO2 or plants. Meanwhile, MGC is planning to acquire ISCC Plus certification at its overseas PC material manufacturing bases, Thai Polycarbonate and MCC Process Plastics (Shanghai).

You May Also Like