Flexible dielectric polymer a candidate for energy storage

Easy to manufacture, low cost, lightweight, and flexible, a new type of dielectric polymer that can operate at high temperatures may be the solution to energy storage and power conversion in electric vehicles and other high temperature applications, according to a team of Penn State engineers.

August 12, 2015

|

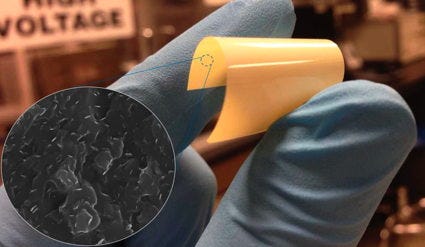

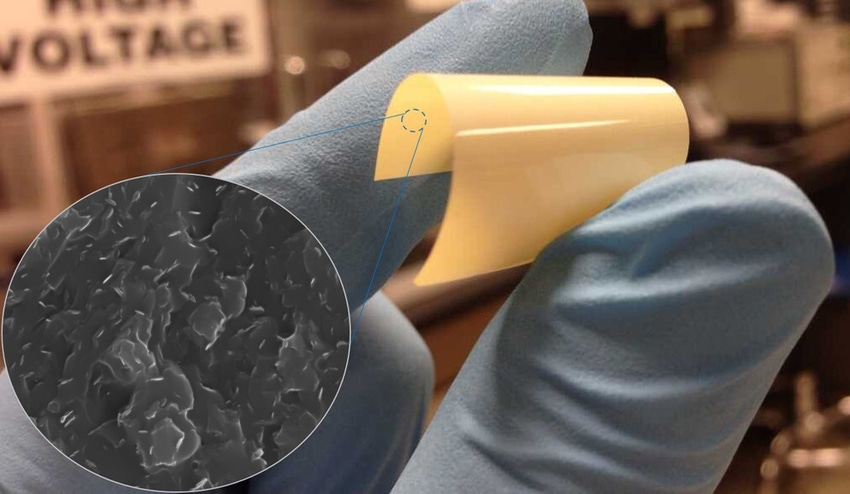

Boron nitride-polymer composite sheet could be a lightweight option for |

"Ceramics are usually the choice for energy storage dielectrics for high temperature applications, but they are heavy, weight is a consideration and they are often also brittle," said Qing Wang, professor of materials science and engineering at Penn State (University Park, PA). On the other hand, "Polymers have a low working temperature and so you need to add a cooling system, increasing the volume so system efficiency decreases and so does reliability," notes Wang.

To overcome this heat resistance issue, the Penn State team selected cross-linked divinyltetramethyldisiloxane-bis(benzocyclobutene) as the matrix polymer. Boron nitride nanosheet are added at a dosage of 10% by volume to impart conductivity. This boron nitride polymer composite can reportedly withstand temperatures of more than 480 degrees Fahrenheit under the application of high voltages.

The material is easily manufactured by mixing the polymer and the nanosheets and then curing the polymer either with heat or light to create crosslinks. Because the nanosheets are tiny -- about 2 nanometers in thickness and 400 nanometers in lateral size, the material remains flexible, but the combination provides unique dielectric properties, which include higher voltage capability, heat resistance and bendability.

Dielectrics are materials that do not conduct electricity, but when exposed to an electric field, store electricity. They can release energy very quickly to enable engine start-ups or to convert the direct current in batteries to the alternating current needed to drive motors.

Applications like hybrid and electric vehicles, aerospace power electronics and underground gas and oil exploration equipment require materials to withstand high temperatures. The cross-linked polymer nanocomposite material has high-voltage capacity for energy storage at elevated temperatures and can also be photo patterned and is flexible. The researchers report their results in a recent issue of Nature.

"Our next step is to try to make this material in large scale and put it into a real application," said Wang. In term of sheet size, "Theoretically, there is no exact scalability limit," he adds.

The Office of Naval Research, Air Force Office of Scientific Research and Dow Chemical Corporation supported this work.

You May Also Like