Glass, Carbon Fiber PP Cuts Weight, Cost in Flexible Auto Designs

Glass and carbon fiber-reinforced polypropylene ensures light, integrated, high-performing solutions according to supplier Borealis.

August 26, 2020

Polyolefin supplier Borealis has made available to the North American automotive market its Fibremod brand of carbon and glass fiber-reinforced polypropylene (PP) grades. The Fibremod family of products enables automotive manufacturers to achieve weight-saving and process cost-saving targets. In turn, replacing engineering plastics and metal parts with energy-efficient and lighter weight PP grades leads to improved fuel economy and lower CO2 emissions.

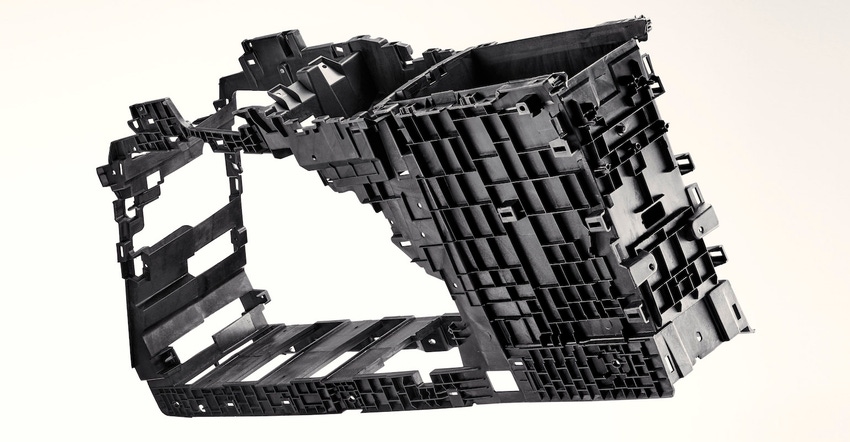

Borealis’ customized carbon and glass fiber-reinforced PP solutions are at the cutting edge in automotive manufacturing, bringing lighter weight, extra strength, and greater impact performance across applications ranging from front end and tailgate modules to instrument panel and center console carriers.

|

Front ends (pictured) and center consoles are examples of large automotive components that can be molded from carbon and glass fiber-reinforced polypropylene. Image: Borealis |

Products in the Fibremod family are a suitable material substitute for metal, and engineered plastics, delivering design flexibility. Short-glass, long-glass and carbon fiber formulations are available, with customizable fiber content ratios, to enable manufacturers to balance strength, weight, and cost according to specific design needs.

Fibremod products also support energy efficiency in production by reducing process temperatures and energy requirements compared with alternative solutions such as polyamide (PA) engineering plastics

About the Author(s)

You May Also Like