Metal-plastic bonding technology developed for automotive and electrical/electronics

Polyplastics’ Quick-10 technology uses quick heating and cooling of inserted metals to realize direct metal-plastic bonding with metal insert molding alone.

May 21, 2018

Engineering thermoplastics supplier Polyplastics has developed a technology that improves metal-plastic bonding of composite parts for the automotive and electrical/electronics industries without the need for pre-treatment of the metal inserts.

|

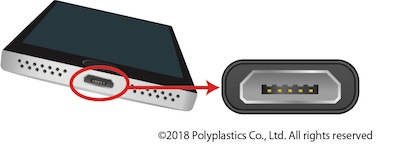

Polyplastics’ Quick-10 metal-plastic bonding technology has been used in mobile device parts (mobile phones, tablets, digital cameras) and some auto-related parts. |

Direct metal-plastic bonding is a process which typically employs metal insert molding. In the traditional process, metal inserts and plastics are firmly bonded via introduction of molten plastic through injection molding to metal inserts which have already undergone appropriate surface treatment. These metal-plastic composites combine the properties of metals (high rigidity, electrical conductivity) and engineering plastics (low density, electrical insulation). However, while numerous factors (metal inserts, plastics, mold structure, injection molding parameters, etc.) generally have adverse effects and prevent stable bonding, Polyplastics has made progress with successful bonding through its Quick-10 technology.

The Quick-10 process uses rapid heating and cooling of metal inserts to realize direct metal-plastic bonding through the injection molding process alone, without any special surface treatment for the metal. The plastics employed must, however exhibit properties such as interface affinity, surface transferability (flowability), and low shrinkage to realize good bonding. To this end, Polyplastics has developed appropriate polyphenylene sulfide (PPS) and polybutylene terephthalate (PBT) grades for the process

A key component of the Quick-10 process is an affinity improvement additive that imparts the metal-plastic interface with enhanced compatibility and promotes maximum adhesion to the metal surface. Polyplastics’ metal adhesion grades include 1135MF1 and 940MA for PPS and PBT) respectively. Additional metal adhesion grades, 1150MF1 and 930MA, provide added functionality.

Polyplastics notes that mold temperature can have a strong effect on bonding. The company has devised optimum molding conditions to achieve good surface transferability and low mold shrinkage with a linear expansion rate close to that of metal.

About the Author(s)

You May Also Like