New PBT Compound Designed for High-Voltage Connectors

The halogen-free flame-retardant and hydrolysis-stabilized grade retains electrical properties under challenging conditions.

August 1, 2022

Plastic components are often exposed to high temperatures along with very strong currents and high voltages in the powertrain or battery of electric vehicles, as well as in the charging infrastructure of electromobility. Connectors, for example, must maintain electrical insulation under these conditions and not allow tracking to occur.

Lanxess has tailored a new PBT (polybutylene terephthalate) compound for demanding high-voltage connectors that is halogen-free flame-retardant and hydrolysis-stabilized. “One strength of the structural material is that its outstanding electrical properties are hardly dependent on temperature and moisture in the typical operating conditions of high-voltage connectors. It can be used at temperatures up to 150°C,” explains Bernhard Helbich, Technical Marketing Manager, Key Accounts, at Lanxess’ High Performance Materials business unit.

The compound is a first representation of the new Pocan BFN HR product range and is characterized by a high level of volume resistance and dielectric strength. For example, the latter is well over 30 kV per millimeter at temperatures up to 140°C (IEC 62431-1). In the CTI test (Comparative Tracking Index, IEC 60112), the material achieves CTI A 600, the highest class possible according to the standard. Elevated tracking resistance reduces the risk of short circuits and defects caused by creepage currents and caters to the growing need for miniaturized connectors.

“But it can also be used at voltages higher than 600 V. The connector design for direct current systems can be optimized for up to 1,500 V in accordance with the design guidelines of the IEC 60664/VDE 0110-1 standard,” says Helbich. The tracking resistance of the compound also hardly diminishes after long-term thermal aging at 120°C or after climate testing.

The material, which is reinforced with 25% by weight of glass fibers, is very stable to hydrolysis. In specimen tests based on the stringent SAE/USCAR-2 Rev. 6 long-term hydrolysis tests of the US Society of Automotive Engineers (SAE), it achieved a good Class 3 rating. The material also passed the UL 94 flammability test of Underwriters Laboratories, achieving the excellent V-0 classification with a test specimen thickness of 0.75 millimeters. With its mechanical properties, the structural material meets common requirements set for high-voltage connectors.

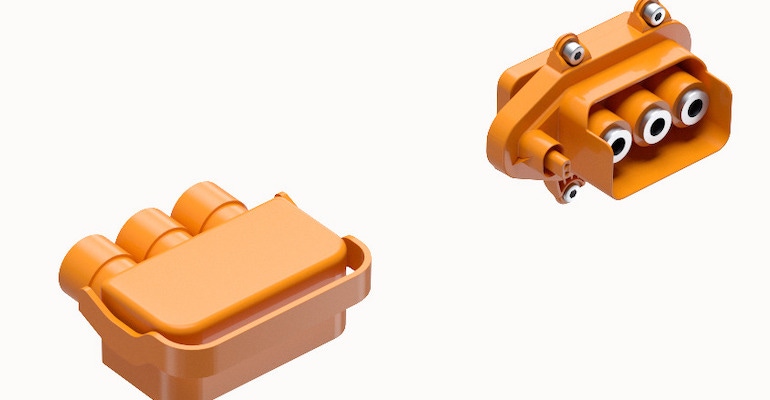

The compound can be colored, including in orange, which increasingly is used in electric vehicles to identify live, plastic-encased components. “Our material and the colorants used remain permanently color stable in high operating temperatures so that the identification is not lost,” explains Helbich. Lanxess wants to have the thermoplastic listed under “All Colors” on the Yellow Card by UL. “In doing so, we will save the processor from the time-consuming UL certification process if they were to color the plastic themselves,” explains Helbich. “They can simply use the compound that we have colored and thus reduce costs,” he adds.

Beyond high-voltage connectors, Helbich sees even more possible applications for the new Pocan BFN HR product range in electromobility and in the manufacturing of miniaturized electrical and electronic assemblies. “We are thinking, for example, of miniature connectors, miniature circuit breakers, terminal blocks, and similar applications,” he says.

Lanxess will showcase these and other developments at K 2022 in Düsseldorf, Germany, on Oct. 19 to 26, 2022. The company will exhibit in booth C76-78 in hall 6.

You May Also Like