New Resin a Step-Change in Fatigue and Creep Performance

Delrin 51HSE resin from DuPont extends metal-replacement opportunities in automotive, e-bike, and other high-performance applications.

September 14, 2023

While DuPont intends to close a deal to sell a controlling interest in its Delrin polyacetal (POM) business to TJC LP by year-end, the engineering thermoplastics pioneer is not slacking on innovation. Its latest offering is a high-molecular-weight nucleated Delrin grade specially formulated for use in applications requiring high creep resistance and fatigue durability. Such applications include e-bikes and automotive.

Delrin 51HSE further extends the ability of polyacetal to replace metal, according to DuPont, helping customers save cost and weight while reducing noise. It also enables smart design concepts that can help to lower carbon footprints.

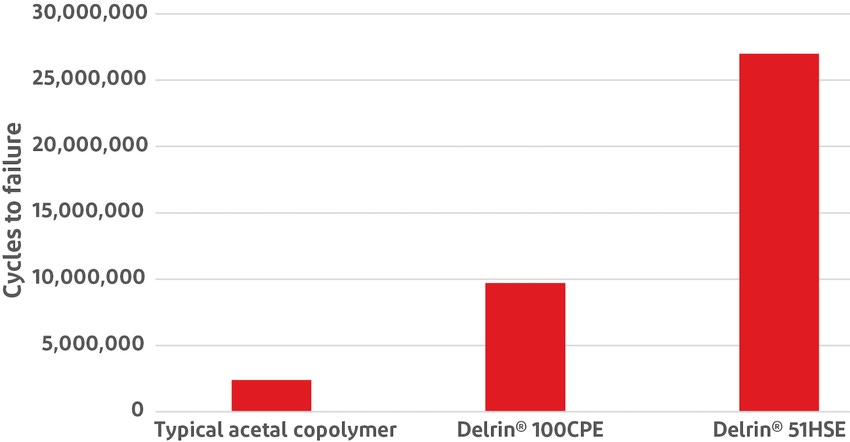

The new Delrin resin draws on a deep heritage of formulations that have set the standard for high-performance plastic gears. While Delrin 100, for example, is known as the designers’ first choice for highly demanding applications, Delrin 51HSE resin furthers those strengths and offers a step-change in fatigue and creep performance.

In a lab fatigue test (shown above), Delrin 51HSE was tested against Delrin 100CPE and a high-viscosity acetal copolymer at 80°C, 30 Hz, and 21.6 MPa load. Delrin 51HSE clearly shows a significant improvement over the comparison products. Testing showed about a 10% improvement in static gear strength, but the real benefit comes from a two-fold increase in durability, giving customers a cost-effective alternative to metal gears or other more expensive solutions.

“Driving innovation remains an intrinsic element of our DNA,” said Sriram Nadathur, Delrin vice president and general manager. “Our customers demand materials that demonstrate unparalleled mechanical performance, exceptional durability, and low global warming potential, without compromising on design flexibility or ease of manufacturing. Innovations such as Delrin 51HSE are the reason why our customers know they can depend on us to deliver world-class resins that fit their most demanding end-use applications.”

About the Author(s)

You May Also Like