Strange bedfellows? Ford and Heinz team up on tomato-based bioplastic for vehicles

While at first sight, cars and tomatoes may not have much in common, the collaboration between Ford and H.J. Heinz is less outlandish that would appear. Every year, Heinz uses more than two million tons of tomatoes to produce its best-selling product: Heinz Ketchup. And every year, the company ends up with a lot of tomato waste. Hence, researchers were looking for innovative ways to recycle and repurpose the peels, stems and seeds left over from making ketchup.

June 11, 2014

While at first sight, cars and tomatoes may not have much in common, the collaboration between Ford and H.J. Heinz is less outlandish that would appear. Every year, Heinz uses more than two million tons of tomatoes to produce its best-selling product: Heinz Ketchup. And every year, the company ends up with a lot of tomato waste. Hence, researchers were looking for innovative ways to recycle and repurpose the peels, stems and seeds left over from making ketchup.

Ford, on the other hand, has long been experimenting with the use of innovative bioplastics and recycled non-metal materials in its cars. Nearly two years ago, Ford began collaborating with Heinz, Coca-Cola, Nike Inc. and Procter & Gamble to accelerate development of a 100% plant-based plastic to be used to make everything from fabric to packaging and with a lower environmental impact than petroleum-based packaging materials currently in use.

Ford, on the other hand, has long been experimenting with the use of innovative bioplastics and recycled non-metal materials in its cars. Nearly two years ago, Ford began collaborating with Heinz, Coca-Cola, Nike Inc. and Procter & Gamble to accelerate development of a 100% plant-based plastic to be used to make everything from fabric to packaging and with a lower environmental impact than petroleum-based packaging materials currently in use.

Therefore, when Heinz approached Ford about possible uses for its tomato waste, Ford was definitely interested. The company was already using bioplastics based on soy and coconut; why not explore the use of tomato fiber to develop a more sustainable bioplastic material? After all, success in developing a new more sustainable composite could reduce the use of petrochemicals in manufacturing and reduce the impact of vehicles on the environment.

"We are exploring whether this food processing byproduct makes sense for an automotive application," said Ellen Lee, plastics research technical specialist for Ford. "Our goal is to develop a strong, lightweight material that meets our vehicle requirements, while at the same time reducing our overall environmental impact."

Although in the very early stages of research, with many questions still remaining, Heinz is also pleased that the technology has been validated and excited about the possibilities this could produce for both companies.

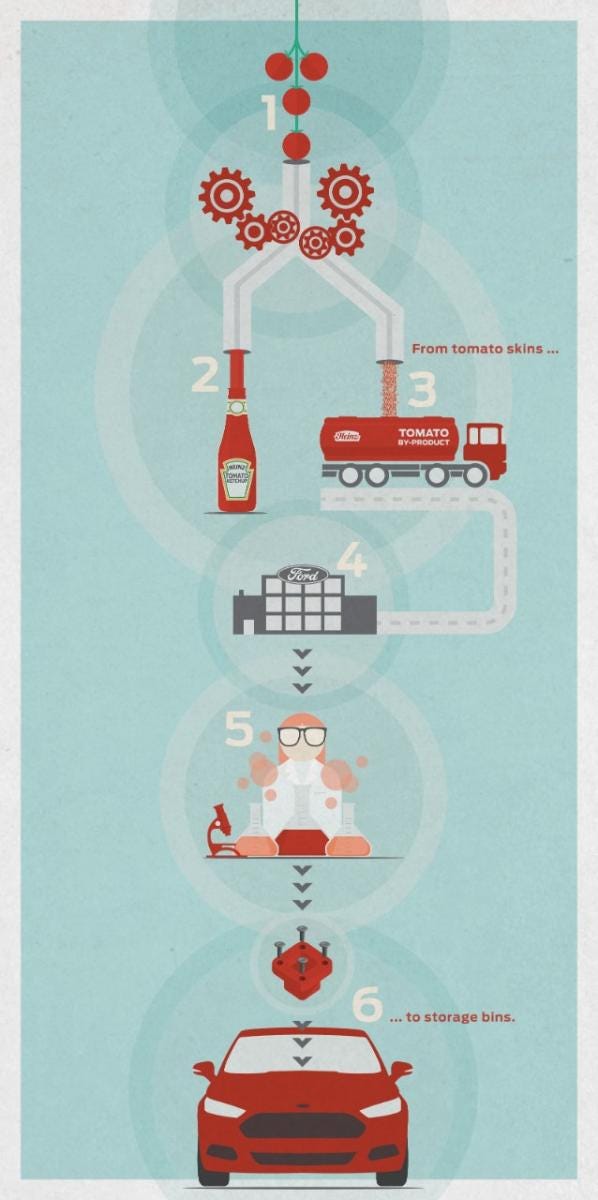

Ford researchers are testing the material's durability for potential use in vehicle wiring brackets and storage bins. Specifically, dried tomato skins could become the wiring brackets in a Ford vehicle or the storage bin a Ford customer uses to hold coins and other small objects.

Ford's commitment to reduce, reuse and recycle is part of the company's global sustainability strategy to lessen its environmental footprint while accelerating development of fuel-efficient vehicle technology worldwide. In recent years, Ford has increased its use of recycled nonmetal and bio-based materials. With cellulose fiber-reinforced console components and rice hull-filled electrical cowl brackets introduced in the last year, Ford's bio-based portfolio now includes eight materials in production. Other examples are coconut-based composite materials, recycled cotton material for carpeting and seat fabrics, and soy foam seat cushions and head restraints.

|

Infographic of the process. |

About the Author(s)

You May Also Like