Thermoplastic Composites Could Be Key to Complex-Shape Aircraft Exteriors

European consortium to develop manufacturing solutions for thermoplastic aircraft rear end.

September 28, 2020

Fuselages of next-generation large-passenger aircrafts look set to rely on the benefits of thermoplastic composites. Greater toughness, recycling potential, and faster production cycles could deliver the capacity to meet future aviation sector challenges.

Thermoplastic composites are already coming into their own in the latest generation of aircraft in smaller components such as seat brackets, as they contribute to lighter airplanes and, consequently, to fuel consumption reduction, but there are still several issues to be overcome for their deployment in larger components.

The manufacturing of complex forms of aircraft rear-end sections with continuous fiber-reinforced thermoplastics poses a considerable challenge: High processing temperatures, raw material costs, complex temperature-controlled tooling, and evolutive cross sections. To support a Clean Sky 2 initiative focused on developing concepts and enabling technologies for an optimum rear fuselage and empennage, ESTIA-Compositadour initiated a European consortium with Heraeus Noblelight (UK), Xelis (Germany), and Cero (France) into a 2.5-year applied research project dubbed Frames: Fiber-reinforced thermoplastics manufacturing for stiffened, complex, double curved structures.

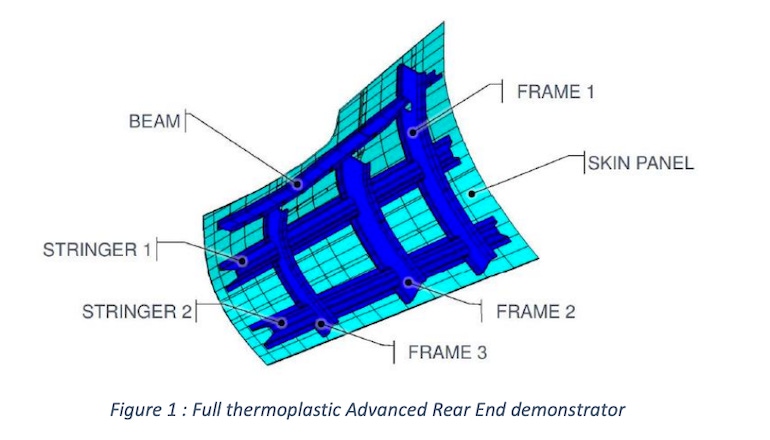

Frames’ main objective is to validate and assess a manufacturing approach to an integral thermoplastic rear end with critical design features. Key technologies developed within Frames will be used in a mid-scale advanced rear-end demonstrator manufactured by the Deutsches Zentrum für Luft- und Raumfahrt (DLR), part of a Clean Sky 2 technology platform for large passenger aircrafts.

By combining their forces and knowledge, the consortium is looking to bring reliable and competitive industrial solutions for intelligent heating systems for automated lay-up, efficient stiffeners production process, and advanced heated tooling. Three work packages will support enabling key technologies: Heraeus Noblelight will lead the development of a combined optical-thermal simulation model for fiber placement with xenon heating devices such as humm3, enabling fast skin lay-up.

For its part, Xelis will undertake the development of robust manufacturing process for complex thermoplastic stiffeners with a proven high production rate capability. Further, Cero will take charge of delivering a self-heating tooling solution enabling a skin-stiffener consolidation process in one shot. ESTIA-Compositadour will lead the project, perform fiber placement trials, and support DLR during manufacturing and delivery of the rear-end demonstrator.

About the Author(s)

You May Also Like