Not all bioresorbables are created equal. Poly lactic acid (PLA) and poly glycolic acid (PGA) are the most common go-to materials for the fabrication of resorbable implants—devices that perform a function and, once completed, are resorbed by the body. They have their drawbacks, however: PLA and PGA may leave behind an unwanted souvenir—inflammation—as they leave the body, and, because they are stiff materials, they do not conform well to the elastic nature of tissue.

January 26, 2015

Not all bioresorbables are created equal. Poly lactic acid (PLA) and poly glycolic acid (PGA) are the most common go-to materials for the fabrication of resorbable implants—devices that perform a function and, once completed, are resorbed by the body. They have their drawbacks, however: PLA and PGA may leave behind an unwanted souvenir—inflammation—as they leave the body, and, because they are stiff materials, they do not conform well to the elastic nature of tissue. Regenerez technology based on poly glycerol sebacate (PGS) from Secant Medical (Perkasie, PA) offers an alternative.

PGS was invented by renowned scientist, engineer, and inventor Dr. Robert Langer, widely considered to be the father of tissue engineering in regenerative medicine, and his post-doctoral assistant, Dr. Yadong Wang. The material notably addresses the compliance mismatch between soft tissues and implants made of PLA and PGA.

PGS was invented by renowned scientist, engineer, and inventor Dr. Robert Langer, widely considered to be the father of tissue engineering in regenerative medicine, and his post-doctoral assistant, Dr. Yadong Wang. The material notably addresses the compliance mismatch between soft tissues and implants made of PLA and PGA.

Emily Ho, Director and General Manager, Advanced Biomaterials and Contract Device Services, at Secant Medical explains. "Compliance mismatch refers to the instance when the physical and mechanical properties of a medical implant do not match the compliance of the native tissue from a chemical and physical perspective," says Ho.

The stiffness of PGA and PLA is a poor match with the properties of human tissue, adds Technical Director Jeremy Harris. "Regenerez is an elastomer that closely simulates the modulus of human tissue, thereby limiting the compliance mismatch issues seen with other materials. In addition to mismatched physical properties, the degradation chemistry of lactides and glycolides creates a locally acidic environment that can induce an inflammatory response, thus delaying the natural healing process," explains Harris. Because Regenerez is composed of glycerol and sebacic acid, which are naturally occurring metabolites, the local pH change is reduced and, therefore, healing is promoted without an acute inflammatory response, adds Ho.

Moreover, PLA and PGA are bulk-eroding materials; as they degrade, the device swells, which is followed by a reduction of mass. "Following mass loss, a significant decrease in mechanical properties occurs in the material," says Ho. "The performance of the device during degradation can result in an uncontrolled performance profile, which can ultimately lead to potential product failure."

Secant Medical will showcase Regenerez at the forthcoming MD&M West event in Anaheim, CA, and discuss some of the applications where its unique properties can have a therapeutic benefit, notably as a coating on biomedical textile structures.

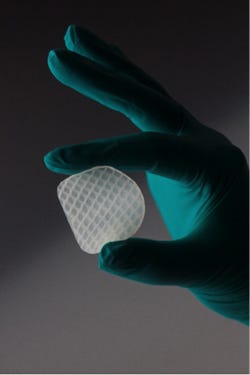

Coating a partially or fully resorbable structure with PGS can improve coating biocompatibility by promoting tissue in-growth, enabling controlled drug release, and solving the aforementioned compliance mismatch issues with bodily tissue, says Secant. Some key features of a PGS coating include conformal properties for fine architectures such as fibrous woven, braided, and knitted structures as well as perforated structures, notes the company. The tunable degradation profile, ranging from 30 to 60 days depending on the material's cure and crosslinking time, as well as the design of the implant and its location in the body, adds Ho, is another desirable property.

PGS has seen significant use on the academic level in the areas of cardiovascular, orthopedic, neurovascular and general surgery, and it has been cited in more than 400 in vivo and in vitro studies. The glacial pace of adoption of new materials in medical manufacturing because of regulatory hurdles and an understandable fear of failure at the corporate level has delayed the arrival of PGS in wholesale medical applications.

Secant Medical, however, sees vast potential in cardiovascular uses of the material, as well as soft and hard tissue repair, and other regenerative medicine applications, and it will take its message to medical device professionals at MD&M West in February.

The nation's largest medical manufacturing event, MD&M West comes to the Anaheim Convention Center in Anaheim, CA, from Feb. 10 to 12. The event is co-located with PLASTEC West.

Norbert Sparrow is Senior Editor at PlasticsToday. Follow him on twitter @norbertcsparrow and Google+.

About the Author(s)

You May Also Like