K 2001: The future of molding

January 1, 2002

In addition to the rollout of 2002 model-year presses and prototypes, there was also a plethora of innovation in process technology showcased by machinery manufacturers at K 2001. High-tech designs and improved speeds and accuracy were a strong focus.

While exhibitors and attendees of K 2001 migrated to Düsseldorf, Germany with mixed emotions and a great deal of economic uncertainty, the world's largest plastics exposition did not fail to impress. The variety of new applications, technology, and products made this a worthwhile trip for anyone working in the molding industry.

While exhibitors and attendees of K 2001 migrated to Düsseldorf, Germany with mixed emotions and a great deal of economic uncertainty, the world's largest plastics exposition did not fail to impress. The variety of new applications, technology, and products made this a worthwhile trip for anyone working in the molding industry.

IMM's coverage of K 2001 starts this month with a review of North American, European, and Asian injection molding machine displays and new machinery products of note. You'll also find a report on the variety of materials at the show. Our coverage continues in the February issue with reports on robotics and automation, auxiliaries, and tooling equipment and components.

Yankee Ingenuity Wows the World

Yankee Ingenuity Wows the World

In all of the 17 halls on the K 2001 fairgrounds, we were able to find only one U.S.-built injection molding machine—an 85-ton/12-oz, all-hydraulic Milacron toggle. The machine was coinjection molding Frisbees with regrind cores, but it had only one barrel. It belongs to the Twinshot Technologies subsidiary of U.S. molder Community Enterprises LLC of Rifton, NY, inventors of the new screw-within-a-screw coinjection works demonstrated on this little press that stopped the biggest plastics show on Earth (see "Rediscovering, Unleashing the Value of Coinjection," December 2001 IMM, pp. 24-25 for the latest report).

When the show opened Twinshot sources explained that they chose an international show to debut their technology because they felt it would be the best place for them to reach the global marketplace. They hoped to interest machinery OEMs exhibiting at the expo in licensing their uncomplicated and cost-saving system. They also hoped to interest molders from around the world to convince their suppliers to do the same. Their plan worked.

By show's end, after coinjecting some 8000 Frisbees, one Twinshot source said, "It would have been a mistake not to come. The response was overwhelming." This source guessed that the company had gathered as many as 1000 serious inquiries. "They saw that our system works on a standard, general purpose machine. That's what they liked the most. There's nothing different about it."

Twinshot also let showgoers dazzled by the new all-electric and hybrid European molding machines at K know that there was something in their good-old-fashioned Yankee ingenuity for them. A poster in the Twinshot booth illustrated that although molders could expect energy-efficient drive systems to help save $4000/year from an annual $190,000 operating cost running a 200-ton all-electric, they could also save $24,000/year in material costs operating the same machine equipped with a Twinshot system.

|

Twinshot's decision to introduce its single-barrel coinjection system at K 2001 reportedly has generated an overwhelmingly positive response from international molders and machinery OEMs. |

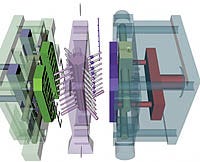

2K Output, Cubed

A 7-metric-ton spinning stack mold with 256 cores and 128 cavities that operates with 40 cooling channels, seven core pulls, eight pneumatic circuits, and a 156-drop Männer hot runner system producing 256 two-component parts every 10 seconds on just a 500-metric-ton press is sure to turn some heads.

It sure did in Düsseldorf. Ferromatik Milacron Europe ran the 4x64 Foboha Cube tool at its booth on one of its hydraulic-clamp K-Tec machines equipped with two shooters for two-component (2K) molding, each with electric screw drives. K-Tecs are available with clamping forces from 45 to 500 tons. (For more on the Foboha cube at K, see "New Turns for Multicomponent Mold Revolution," November 2001 IMM, pp. 59-60).

An A-Eye on Molding Perfection

At K 2001, sources from Fanuc, the biggest supplier of all-electric injection machines in the world, announced that the company's latest upgrades allow molders to attain nothing less than molding perfection. They say perfect molding requires perfect machine repeatability, mold protection, and QC. Ejector control monitored by artificial intelligence (AI) and a material evaluation system are among the newer features that have been added to the Roboshot's existing mix of solutions to help close the perfection loop.

Fanuc's AI ejector control senses the ejector motor torque required to push the ejector forward. If any resistance is detected, and if the level detected exceeds fault limits set in the memorized ejector motor profile, the machine stops. The Roboshot's mold protection system does the same thing for the clamp motor. It has been upgraded to protect the mold by detecting stuck guide pins, stuck slide cores and angular pins, and jam-ups. With these Fanuc believes it has perfected mold protection.

Its materials evaluation system uses the molding machine itself to test melt viscosity by automatically sampling the effect of different injection velocity and barrel temperature settings on a material. Pressure readings also are recorded. Sampling takes less than 30 minutes.

Data from these viscosity calculations are transmitted to Fanuc's Mold 24 host computer system for analysis and documentation. Viscosity data comparisons when changing to a new lot of material can help setup techs properly adjust machine parameters to obtain the best molding conditions.

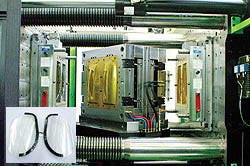

|

A multimolding big shot: One of Engel's latest multimolding solutions on display at K was this 990-ton, two-platen Duo machine. It featured the company's Combi-Cleanshot multiple injection unit system and a 2K stack mold with a horizontal rotary center block spinning an HTP Formenbau mold. The second injection unit is mounted behind the moving platen. Engel's Cleanshot shooters are specially designed for molding transparent resins. Clear PC automotive headlight lenses were produced at K (inset), complete with molded-in seals, in 50-second cycles. Duo Combi presses are available here with clamping forces up to more than 6000 tons. |

AI Metering

When it comes to perfection in machine repeatability, Fanuc believes it is already there to a great extent with its real-time AI pressure profile trace control. The next step was demonstrated at K 2001 on a 165-ton Roboshot Alpha-i machine molding 35.6g yogurt cups run in a four-cavity Fostag tool in 2.5-second cycles.

Repeatable melt conditions through a dosing time of .8 second were achieved using AI profile trace control over metering. Resin transfer is stabilized on the fly as the machine follows an ideal screw speed and retraction profile trace, thereby perfecting melt conditions with every shot.

Fanuc sources announced at K 1998 that the company had shipped 7500 of its all-electric injection molding machines since introducing them in 1984. Since K 1998 at least 4500 more have been shipped. Of the 12,000 Fanucs now in the field 6080 are in Japan, 1020 are in Europe, 2160 are in Asia, and there are 2740 more in North America.

Ferromatik Milacron North America is the exclusive distributor of Fanuc machines in the U.S. Its latest series of four-servo Roboshot Alpha-i presses comes in six models, ranging from 16.5 to 330 tons, with 15 different screw sizes from 16 to 68 mm, and AI CNC controls.

Injection Molding Wood

Wilmington Machinery believes it has successfully developed technology for the structural foam molding of pellet-sized PP-based composites filled with wood fibers. Though the company had been working on the project for the past few years, Wilmington sources at the show told us that success came only within three months prior to the show. Drying the composites and stabilizing additives were the keys.

"Wood is hygroscopic. If moisture is present during extrusion, it burns. In addition to proper drying, we found that we had to deny the presence of oxygen in the extruder," this source says. Wilmington blankets the low-shear, fixed-extruder screw of its two-stage injection unit with deoxidizing agents and cooling gas.

Wilmington has been working with Onaga Composites (Onaga, KA), supplier of the wood-filled concentrates, which are already gaining in popularity among extruders. An inline compounding/injection molding system could help reduce the heat history of the wood fibers. Wilmington sources believe such systems will come in time.

Wilmington also has found success foaming parts with a supercritical carbon dioxide fluid. "Unlike nitrogen, carbon dioxide is solvent. At the right pressures it goes right into solution, altering melt viscosity and improving flow, which can make the molding of fractional melt polymers, like those in recycled bottles, and the structural foam molding of larger, lighter-weight parts, viable possibilities."

|

Wilmington Machinery has developed a two-stage injection unit designed for molding wood-filled polyolefin composites. A machine in its lab is available for trials and development work. |

Hey, Beer Here

Kortec's coinjection molding systems for multilayer PET preform molding are gaining in popularity worldwide. Sources at K 2001 said that 25 percent of the orders it receives now come from outside North America. Offshore orders are expected to rise soon to 50 percent. A Kortec customer in China has announced the production of the world's first pasteurizeable PET beer bottle. Ninety percent of the world's beer bottles presently go through the high heat and pressure of the pasteurizing process.

Kortec's turnkey systems now are available in four series:

• Lab Series: Systems with small-tonnage machines designed for multilayer preform and container development projects, featuring interchangeable tooling to accommodate different preform designs and sizes.

• Intro Series: Designed for market introductions, these systems feature a Kortec coinjection spin on Husky's vertical-axis rotation Index system, which operates single-, dual-, and quad-faced modes that match production to demand.

• Pro Series: Kortec's workhorse coinjection systems, which operate at mono-layer cycle times, equipped with 24- to 74-cavity coinjection molds.

• Ultra Series: Kortec's newest is a high-volume solution, featuring multi-layer preform molds up to 96-cavities.

Ultrahigh-speed Molding

Jaws dropped last summer in Chicago as show-goers watched Nissei put its 15-metric-ton Model ES200H all-electric through its paces at NPE 2000. It ran fine-pitch LCP connectors in two-cavity tooling at .68-second cycles. Following a few technical modifications to its center-drive injection unit and toggle clamp since then, Nissei amazed the K 2001 crowds by running it even faster. It clocked in with .63-second cycles. It was displayed with an optical part-quality inspection system of Nissei's design—the only way to keep an eye on such small parts being molded so fast.

The ES200H has an injection speed of 350 mm/sec. Not quite fast enough for you? Well, try this: Nissei also displayed the latest version of its UH Series machine—the only hydraulic press in its K 2001 booth. UH Series machines used to shoot at 1500 mm/sec. The 90-ton model UH2000/TM reportedly maxes out at 2000 mm/sec. This challenges the 2000 mm/sec injection speed of what many believe to be the fastest press on the planet, the Fanuc Supershot 100i, an all-electric driven by ultrahigh-speed linear servomotors.

|

|

Kortec's new Ultra series of systems for producing multilayer PET preforms is available with molds up to 96 cavities. Such high-volume output may soon be needed for bottling beer. |

Electricity Comes to Europe

At first, it seemed the most talked-about item around the European-based machine manufacturers' stands at K 2001 was electric machines. Companies with new lines talked about the benefits, particularly in precision, while those without them talked about the high performance levels possible with hydraulic and hybrid machines. Oh yes, those with new all-electrics also talked about the high performance of their hydraulic and hybrid machines. Confusing? Not really. They are saying electric machines are part of what molders need, and therefore they are part of the manufacturers' product range. Not one of them is abandoning hydraulics.

Once in a stand, whether it contained all-electric machines or not, talk quickly turned to the processes being demonstrated, many of which involved turning or spinning of some kind, which was exemplified by the previously mentioned Foboha Cube tool running at Ferromatik Milacron's booth.

Until recently, there were only a few choices in multicomponent molding: move the part to another machine or rotate half the mold. At K 2001 a new axis was revealed as manufacturers spun mold center plates 90°, 180°, or 270° on the vertical axes; or they turned a center plate or core inside the mold, or they changed materials inside the mold without it opening between shots.

Demag Ergotech, which is extending its El-Exis line of hybrids up to 350 tons, demonstrated spinning stack molds using technology from Gram Technology (Denmark). A 150-ton El-Exis E molded PP syringe bodies in a 48-cavity Schöttli mold in 8-second cycles. Not to be outdone, a 200-ton El-Exis S (hydraulic clamp and secondaries) molded PC/ABS mobile phone housings in a 4x4 Männer stack mold in 4-second cycles.

Gram's technology uses a rotating center plate inside the mold. It allows up to four injection stations, and at K it was molding a three-shot, 2K dialysis tube connector. For it, PP was injected as the base, the mold opened, the center turned 90°, the mold closed, and TPE was overmolded. On the next 90° turn, the same PP was overmolded and the part was removed. It solves a bonding problem between the two materials, which in the actual part are PP and PVC. A Demag DR 621 NC robot removed the TPE sprue during rotation. One of the advantages claimed by Gram is that with the spin inside the mold, it requires only a standard machine, such as the 50-metric-ton 2K Ergotech Multi.

|

|

Micro multimolding: The manufacturers of the 6.2-ton Babyplast 6/10 molding machine have developed an all-in-one, retrofittable injection unit that costs only $15,000. It features a direct-connect plate for installation anywhere on a mold, rather than on the machine. As on the Babyplast 6/10, the injection units use an angled two-stage design. They have no plasticating screw and no heater bands. A piston forces resin through steel ball bearings into a shooting chamber, melting the pellets through shear. Another piston injects the melt. A vertical parting line injection version of the Babyplast 6/10 (right) for insert micromolding also was introduced at K 2001. It costs $20,000. Babyplast machines are sold in the U.S. by Ferromatik Milacron. |

Design Meets Machine

Attention is being paid as never before to machine design, and the results were visible at K. Every maker of a new all-electric machine—Battenfeld, Ferromatik, Mir, Krauss-Maffei, Engel, Negri-Bossi, and Netstal—emphasized the modern looks of their machines. The nonelectrics are also getting higher-tech.

When Battenfeld's head of R&D, Thomas Kosthorst, gave IMM the rundown on Battenfeld's new EM series of all-electrics, he noted all the technical features. Precision being paramount, he pointed out the machine's high stiffness, fast monitoring time, infinite servomotor setpoints, and more. He also stepped back now and then to say, "It's really good-looking, isn't it?" or, "Look at how modern the lines are." We have not heard talk like this from manufacturers in the past, but for molders looking to impress potential clients, this is good news.

Battenfeld had other new machines to talk about, and again it was processing that dominated the conversation. A 160-ton TMS machine, which is the new high-speed version of its TM Series, was fitted with a Waldorf Technik double inmold labeling line and a variety of Battenfeld-designed placement and handling gear. It yielded about 1400 labeled PP margarine tubs (.45-mm walls) per hour from a two-cavity Hofstetter mold. A 210-ton (230 U.S. tons) TM machine demonstrated Battenfeld's Aquamould water-assist injection technology at the IKV Institute's stand. The IKV, which did the development work for water assist, molded a two-component beach ball racket. Water cored out the frame and handle in the first shot of PP; a second shot of another PP formed the racket's surface.

|

|

Turnkey PET: Chen Hsong of Hong Kong, believed to be the largest injection molding machinery OEM in the world, returned to K with a fully automated turnkey PET preform molding system. It was built around a 275-ton model CP-M110 that runs a 32-cavity Chen Hsong hot runner mold. The total system sells for $450,000. Chen Hsong sources also tell us that they now represent Alliance Gas Systems' gas-assist equipment in Asia. | Microcellular molding is electrified: The Japan Steels Works Ltd. (JSW) displayed its latest J-ELIII Series all-electric molding machines at K 2001. An 85-metric-ton Model J85ELIII was equipped for microcellular foam processing. JSW was the first Japanese machine builder licensed by Trexel Inc. (Woburn, MA), the exclusive worldwide commercial developer of the MuCell process. JSW has combined all of the reported productivity and product quality benefits of MuCell and all-electric process technologies in one package. |

|

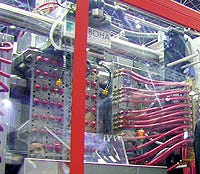

|

If you were in the machinery hall, you likely saw this view. This rotating 2K stack molding system, developed by Ferromatik Milacron and Foboha, reportedly will save their customer more than 40 percent in material cost. | A Korean all-electric: Woojin Selex, the largest Korean injection press manufacturer, brought a model of its new Selex-EA Series all-electric machines to K 2001. The machines feature a 300-mm/sec injection speed, 1000-mm/sec clamping speed, ±.01-mm position accuracy, and part weight variation of only ±.03 percent. The 110-ton show machine sells in the U.S. for about $90,000. |

|

|

Gram Technology, Denmark, showed its spinning center plate technology with marketing partner Demag Ergotech. The first shot of this dialysis connector is PP. The second shot is TPE (blue), which is overmolded with a third shot of PP. The fourth station allows part extraction simultaneous with the three shots. |

Disks and Other Specialties

Specialty machines designed for either specific market niches or specific processes were numerous among the European machine manufacturers' booths at K. The Netstal e-jet optical disk system was introduced months before the show at a press conference with enough smoke and colored lights to impress Michael Jackson. This is Netstal's latest push in a market where formats continue a fast evolution. Just as we are learning about DVD, along come several formats of recordable DVD. The e-jet is made to mold them all, and future formats, too. It handles twin-cavity molds, has advanced closed loop controls, and a 2.5-second cycle time. At K, Netstal also showed a "project study" all-electric machine, but said it would not be available until 2003.

|

Negri-Bossi's all-electric Elma Series (90 to 210 metric tons) is built on the CANbus all-digital machine control architecture. |

Krauss-Maffei was ready with the all-electric version of its Triathlon optical disk system, and it too is designed with looks in mind. The company says that with 18-GB disks already in limited use, all-electric is the only way to meet the tightening tolerance demands. Krauss-Maffei talks similarly about its new Eltec all-electric machines, still another entry in the machine beauty pageant.

|

A 100-ton model of the new M2C Series (60 to 200 tons) molding machines was on display in the BMB stand. Two tiebars are mounted diagonally to allow use of oversized molds or large slide mechanisms. The toggle clamps are also positioned diagonally behind the corners of the moving platen that have no tiebars. At K 2001 the machine was molding inmold-labeled food tubs at high speed. |

The Eltecs offer clamps of 50 to 150 metric tons, injection pressures of 1500 to 3000 bar, and injection speeds of 100 to 300 mm/sec. Two servomotors sit inline on the back of the screw, one for injection and the other for plasticating. Krauss-Maffei was also loaded with process innovations. Its IMC in-line compounding system molded an auto tailgate made of long-glass-fiber-reinforced ABS injected behind a multilayer film already in the mold. IMC combines a twin-screw extruder with a special injection unit and uses gravimetrics to feed polymer and additives such as long-fiber glass.

Engel's new e-motion all-electrics (55 to 200 tons) stay with the company's basic no-tiebar design with a few modifications to accommodate the new machine's toggle mechanism. Showing some spin of its own, Engel unveiled its Duo Combi multiple injection machines with the second injection unit behind the moving platen where an ejector would normally be. A rotation module lets the center mold plate turn on its vertical axis and parts are removed laterally by an Engel robot to avoid contamination from above.

Arburg showed its new Allrounder A Series, which, though it offers servo-electric options on clamp, injection, and dosing modules, is not called an all-electric machine. The company added a 320-ton model to the Allrounder S range and a new vertical implementation of the Multilift robot system. Processes on display included micromolding, thermoset, insertion and encapsulation, MuCell, LSR, sandwich molding with gas, and multimaterial with yet another spin variation.

The rotary table in an Allrounder machine turned a specially designed Weber mold 120° between shots. The first two turns inject materials. The third turn brings the parts to an open space where they are removed by a Multilift H robot while the mold is closed. Total cycle is 15 seconds.

|

|

Sandretto's new Nove S Series toggle-clamp machines and Krauss-Maffei's all-electric Eltec Series were designed to be sleek and modern in appearance—a trend driving many machine manufacturers. |

Sandretto's stand was also rife with processes such as gas-assist, multimaterial variants, and hybrid machines. Opting not to follow the all-electric trend, Sandretto unveiled its new Nove S Series toggle-clamp machines with forces of 75 to 485 metric tons. Designed for speed, accuracy, low maintenance, and reduced energy consumption, these machines also offer a very modern look, even compared with previous Nove Series machines.

You May Also Like