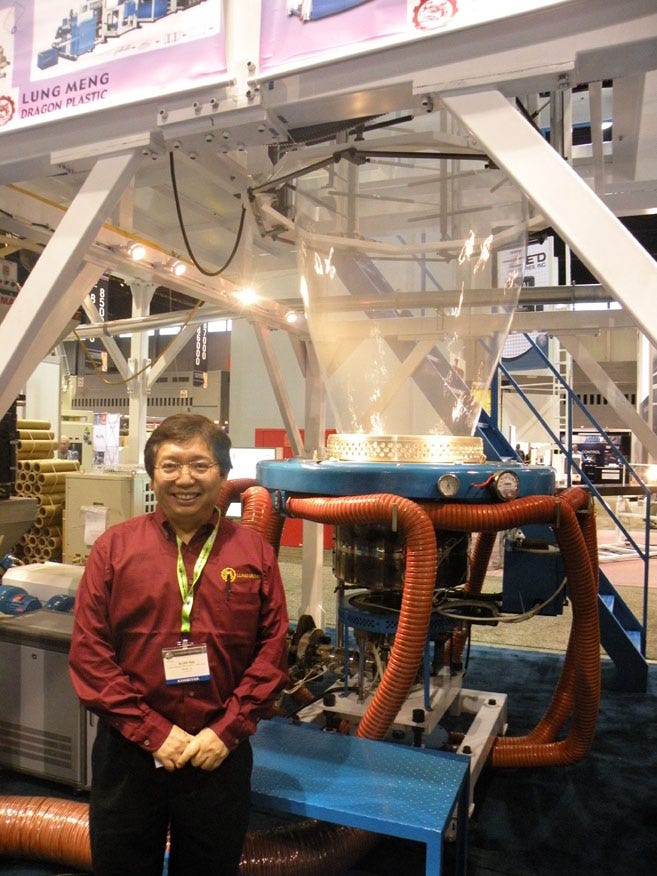

Lung Meng’s the only blown-film tower running at NPE

Chicago, IL—Noticeably absent from NPE2009 were rafter-scraping film towers running blown-film applications, as many suppliers still came to Chicago, and brought equipment, but left it idle. The lone operational system could be found in the North Hall and was brought by Taiwanese equipment supplier, Lung Meng Machinery (Tainan Hsien).

June 29, 2009

Chicago, IL—Noticeably absent from NPE2009 were rafter-scraping film towers running blown-film applications, as many suppliers still came to Chicago, and brought equipment, but left it idle. The lone operational system could be found in the North Hall and was brought by Taiwanese equipment supplier, Lung Meng Machinery (Tainan Hsien).

|

The AH75T monolayer system with 3-inch extruder and winder was running an Exceed mPE (metallocene polyethylene) from ExxonMobil for a stretch film product. Allen Tsai, general manager of U.S. operations for Lung Meng Machinery Inc. (Doral, FL), said the company had planned to have two operational systems in its booth, with a larger three-layer coextrusion line joining the stretch-film system, but as reports of pullbacks by competitors surfaced, the company scaled down its plans.

The second line, which would have blown a three-layer garbage bag, was to be paired with an inline slitting and packaging system to produce finished boxes of garbage bags. The company still brought the inline packaging system, as well as an automated pre-stretching system for shrink film that reduces stretch-film thickness from 21 to 8 µm, while boosting strength. The company described its booth as a demonstration of its new whole-plant system, offering film manufacturing to bag packaging.

Tsai said the company never wavered in its commitment to run a line in Chicago, adding that NPE2009 had been busy after relatively slow events in Asia (Chinaplas) and Europe (Italy’s Plast). “We’re a machinery company,” Tsai said, “we don’t just want to show customers a catalog.” The AH75T has a maximum film width of 1600 mm and output of 200 kg/hr in high-density PE and 230 kg/hr in low-density PE. —[email protected]

About the Author(s)

You May Also Like