The molding process is a science and an art at Winzeler Gear

Is the molding process a science or an art? At Winzeler Gear, you don't have to separate the two. The company blends both in order to design and manufacture high precision high-tolerance molded plastic gears for the automotive, lawn and garden and office automation industries.From the gallery of Fashion Gear Art to a distinctive new machine design and the walls of its facility in Chicago, you see the influence of modern art, fashion, design, and contemporary engineering in all aspects of the business.

March 19, 2014

Is the molding process a science or an art? At Winzeler Gear, you don't have to separate the two. The company blends both in order to design and manufacture high precision high-tolerance molded plastic gears for the automotive, lawn and garden and office automation industries.

From the gallery of Fashion Gear Art to a distinctive new machine design and the walls of its facility in Chicago, you see the influence of modern art, fashion, design, and contemporary engineering in all aspects of the business.

Winzeler Gear has adopted the principals of scientific molding as a foundation in their business model. These principals

|

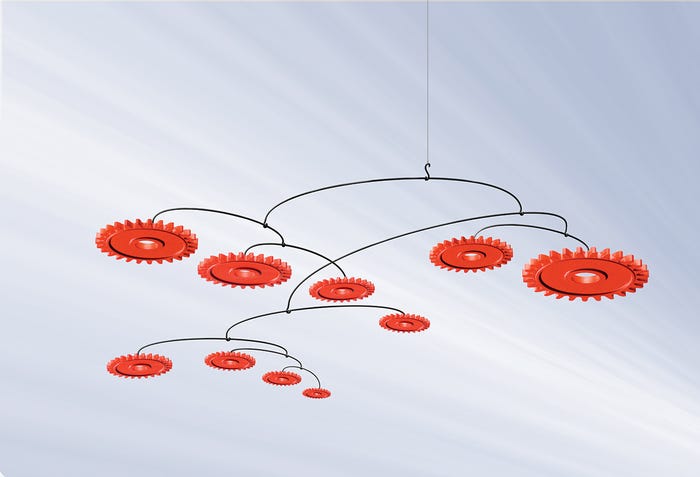

An example of Winzeler Gear art collection. |

are used to develop and control 100% of all molding processes, ensuring minimum variability in gear dimensions and material integrity. With full corporate investment, all of its process engineers are trained and certified by RJG Inc., a provider of injection molding training, technology and resources, to assure they understand the science of molding and the scientific approach to process development and control. This specialized training in scientific and de-coupled molding allows Winzeler to develop and maintain a precision production process for all gears manufactured in their facility.

To develop the process, cavity pressure sensors are used at the prototype molding phase of each program. If gears molded with the prototype process meet dimensional and durability requirements, Winzeler can ensure a smooth transition from prototype to production by matching the pressure fill curve template. When in production, the RJG computer must accept the process every cycle before the gears are allowed to flow into a "good" part container. The approval signal is stored on a production server, providing a record of 100% process validation by cycle with a date stamp.

This systematic approach to molding is the core of Winzeler Gear's philosophy to maximize quality and consistency without subjective intervention.

Long-time partners

If both art and science serve as the backbone of the business, you can also say consistency does as well. The company has worked with both Engel and DuPont for more than 30 years.

As the company's prime material partner, 90% of all the company's molding material is supplied by DuPont, with the majority of that material being Delrin acetal resin, which is suited gear applications. The two companies also work closely on research and development and global marketing.

Engel is Winzeler's only machine supplier.

"The Engel machines are durable and reliable, which serves us both well," said John Winzeler, president of Winzeler Gear. "Re-qualifying machinery for the automotive business is difficult, and the long life of the Engel press means that we seldom have to go through the procedure. Winzeler Gear produces high-quality, high-precision gears, and for that we require an injection molding machine that meets the same standards."

Recently, Engel installed five of its e-victory injection molding machines -- four Engel e-victory 200/65 models and an Engel e-victory 740/160 -- at the Winzeler Gear facility in Chicago.

All gear production is performed on horizontal Engel machines, with more 50% of the 39 machines in the facility being tie-bar-less.

"The Engel tie-bar-less design provides us with the ultimate flexibility when designing our automation, and is the only machine we purchase" Winzeler said. "The molding plant dynamics would be changed completely if we had to rely on conventional machine designs."

The company uses a combination of linear and six-axis robots when automating its systems, along with automated box loading with bar coding traceability. The focus on automation is to ensure consistency of production and eliminate human intervention.

In addition, Winzeler Gear engineers have developed a plant wide mold transfer and storage system. The team designed the system, including a mold cart, with storage centers located near the machine cells. Each storage center (or mold rack) holds approximately 10 molds, which are stored within easy access of the machine they run on as opposed to one large central storage area. The company says that this allows for a much quicker mold change and improved efficiency.

About the Author(s)

You May Also Like