The year's top innovations in molding and extrusion technologies

While 2015 did not deliver what I would call breakthrough technologies in molding or extrusion, suppliers are always coming up with new tools to help moldmakers build molds that achieve faster cycle times and produce better parts and to improve extrusion processes. They did not disappoint this past year. Hot-runner systems, in particular, sizzled in 2015, as evidenced by the sheer number of hot-runner system suppliers at NPE2015. Here is my top 10 list of advances in moldmaking and extrusion in 2015.

December 19, 2015

While 2015 did not deliver what I would call breakthrough technologies in molding or extrusion, suppliers are always coming up with new tools to help moldmakers build molds that achieve faster cycle times and produce better parts and to improve extrusion processes. They did not disappoint this past year. Hot-runner systems, in particular, sizzled in 2015, as evidenced by the sheer number of hot-runner system suppliers at NPE2015. Here is my top 10 list of advances in moldmaking and extrusion in 2015.

Synventive Molding Solutions (Peabody, MA), a business of Barnes Group Inc., proved that hot-runner systems are a critical component in automotive molds. The company showcased what its hot-runner systems are capable of by displaying a 2015 Corvette in its booth at NPE2015. Now, if that didn't catch the eyes (and hearts) of moldmakers, nothing will.

Synventive Molding Solutions (Peabody, MA), a business of Barnes Group Inc., proved that hot-runner systems are a critical component in automotive molds. The company showcased what its hot-runner systems are capable of by displaying a 2015 Corvette in its booth at NPE2015. Now, if that didn't catch the eyes (and hearts) of moldmakers, nothing will.

Synventive is all about control with its complete line of Synventive activeGate tool-based molding technologies: nuGate, hGate and Valve Pin Position Monitoring options; and modular actuators and SynCool 3 passive cooling for valve-gated hot runner systems. Then there's Synventive's SynFlow, which offers much more than just open/close—once thought to be enough, commented Bill Rousseau, Chief Engineer at Synventive. "Now we can expand on this progression in two stages. We can control the opening and the flow front," he said.

The new patented SynCool 3 passive cooling system is designed to work with the new line of Synventive modular actuators: No water-cooling lines are needed; it offers immediate tool removal without cooling; preheats without damage to actuator or seals; and eliminates downtime caused by clogged water lines.

Controlling water flow

Gammaflux L.P. (Sterling, VA), a global supplier of hot-runner temperature-control systems introduced two new options for its G24 hot-runner temperature-control systems product line at NPE2015, designed to help increase productivity and profitability for injection molders. And who doesn't like the P&P in the molding business? Water flow is key in molding good parts, and most moldmakers are well aware of how critical water lines are in protecting water and valve gate seals in hot-runner systems. Gammaflux's new Water Flow Monitoring option employs dual output flow and temperature sensors in the molding cell to monitor and ensure proper water flow throughout the mold. Gammaflux noted that its products "are so much more advanced than they were even a few years ago" and have evolved into production monitoring systems for molders.

"Good parts are highly dependent on adequate cooling in the mold to control various aspects of the molded part, including finish, shrinkage and general dimension repeatability," said Mike Brostedt, Gammaflux Director of Market Development. "Monitoring multiple points of temperature, pressure and flow throughout the mold can identify problems prior to quality control rejection and document production for critical applications. All of these products are simply to help molders prevent common problems from occurring to maximize uptime and make better parts with optimum cycle time."

AST Technology (Wauconda, IL) knows that the efficiency of mold cooling circuits is critical to a stable process and the manufacture of high-quality, dimensionally stable parts. The company's new System Cooling platform gives molders the ability to monitor water flow and temperature circuits inside the mold. "There are monitoring devices for mold pressure, injection speeds, cycles and cycle times, but there has not been a comprehensive system for tracking water flow and temperature through the entire mold until now," explained Sujit Sheth, AST's General Manager, Monitoring Division. "Cooling constitutes 60% of a mold's overall cycle time—that means it should be a factor we can harness to help reduce or control cycle times and stabilize part quality."

System Cooling fills that role by monitoring every circuit in the mold individually. With other systems, pressure loss can only be detected based on the time the water goes into the mold compared with when it comes out. System Cooling can protect the mold and improve quality by quickly identifying cooling problems and alerting the user to various common cooling circuit problems, such as no water flow from the mold heater, blocked waterways, scale/rust build-up, and incorrect piping.

Hot runner system reduces thermal variation

Hot runner system reduces thermal variation

Mold-Masters (Brampton, ON, Canada), a business unit of Milacron, introduced its Summit Series hot runner for premium applications this year. The stainless-steel hot-runner system, showcased at NPE2015, runs with four times less thermal variation from set point, compared with the typical thermal variation seen in a nozzle with a heater band, the company claims. With less than 5% temperature variation, this nozzle series is suited for molding shear and temperature-sensitive resins like PC, POM and PBT. The nozzle profile is especially effective for medical molding, where precision is tantamount. New valve gating methods using servo-controlled actuators bring top-of-the-line performance to the hot-runner market.

Milacron (Cincinnati, OH) also announced its enhanced Fusion G2 series for automotive and large-part molding. An extended nozzle length range provides more flexibility for customers, while the new valve pin open speed control and position monitoring option enables more control over resin flow and the molding process, resulting in an improved surface finish. Additional new gate seal options enable handling of new and challenging resins.

For molders who want to see details about their molds that have never been possible before, there is SmartMold technology: Contactless wet cycle counting, uptime and cycle time sensing, over pressurization, over temperature, over tonnage and abuse of the mold can be easily sensed and recorded to ensure that the mold is running as intended. All of this is possible without the need for clumsy and invasive parting line sensors, pressure transducers, wiring or thermocouples. The collected data is seamlessly transferred to production monitoring systems.

Users can interface with SmartMold via a compact, multi-touch screen mounted directly on the mold or via a smartphone using a Bluetooth or Wi-Fi connection. Customers can now locate their molds anywhere in the world, and SmartMold will automatically notify the user and supplier of the pending need for parts or service. SmartMold opens the door to a world of possibilities never before seen in injection molding, claims Milacron.

World's first nine-manifold extrusion die

Nordson EDI (Westlake, OH) recently introduced co-extrusion technology that enables film processors to achieve tighter thickness tolerances for the individual layers in a multi-layer structure. Nordson has manufactured what it claims to be the world's first nine-manifold extrusion die yielding multi-layer film with two-thirds less layer thickness variation. The new technology is particularly suited to processors with high-throughput lines dedicated to a narrow range of products.

The nine-manifold flat die has been successfully commissioned, and is producing nine-layer film from various resins. While the degree of improvement will vary with the application, in general, Nordson EDI's nine-manifold die technology promises to reduce variation in individual layer thickness from the +/- 15% tolerance often encountered with comparable advanced feedblock systems to +/- 5%, according to Sam G. Iuliano, Chief Technologist for Nordson EDI. "The greater accuracy achievable with multi-manifold dies enables processors to run thinner layers of the costly specialty materials often required for high-performance packaging films, while at the same time enhancing product quality and consistency," said Iuliano.

Interest in conformal cooling heats up

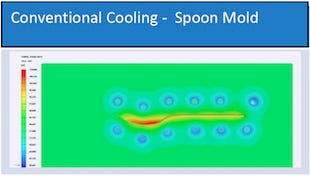

Interest in conformal cooling technology is heating up, as both OEMs and moldmakers look for ways to get better cooling into the mold, particularly for complex parts. Conformal cooling technology in injection molds was originally developed as a way to create cooling (water) channels that follow, or conform, to the shape of the molded part in order to get cooling close to critical areas that otherwise would be difficult to cool, such as thicker sections or areas that have thin-to-thick walls. Conformal cooling technology offers a more uniform way to cool the parts, thus reducing cycle time and improving both productivity and part quality.

While conformal cooling has been used for many years, various new developments have improved the way conformal cooling lines are produced to prevent leakage and mold damage. One innovative method is "plate fusion technology" from Polyshot Corp. (West Henerietta, NY), which the company claims has helped customers see a 39% cycle time savings in one particular application.

The advent of 3D printing, aka additive manufacturing, using the direct metal laser sintering (DMLS) and selective laser melting (SLM) processes brought new opportunities to improve conformal cooling channels in injection molds. Linear Mold & Engineering (Livonia, MI), now Linear AMS after the sale of 70% of the company to Moog, is seeing big demand for its conformal cooling channels in molds created using both the DMLS and the SLM 3D metal printing machines. Linear, an early adopter of AM technology, has made it a core competency.

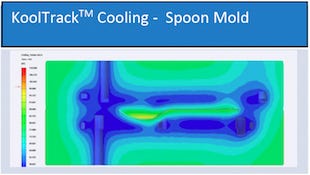

StackTeck Ltd. (Brampton, ON, Canada) introduced its KoolTrack conformal cooling technology at NPE2015. It was the culmination of several developments, combining the company's ability to simulate heat transfer in the part and molding surface components with a proprietary bonding technology. The bonding process in the manufacture of molding surface components allows for intricate cooling channels to be cut in steel parts that are then bonded together to make cores and cavities that have cooling circuits inside. This is providing cycle time savings of 10 to 15% for sub-10-second cycle times, the company claims.

|

|

It's been a long road to bring mold manufacturers to the point where they use 3D printing to bring real value to their business, but it's finally taking hold. Hasco (Lüdenscheid, Germany), a worldwide innovative moldmaker, and Stratasys Ltd. (Eden Prairie, MN), a global provider of 3D printing and additive manufacturing solutions, announced that Hasco has developed a rapid, cost-efficient method of producing low volumes of injection molded prototypes by integrating Stratasys 3D printing with is K3500 quick-change mold system. Using this innovative approach, molders can quickly change between inserts for different products, enabling them to cost-efficiently produce low volumes of injection molded parts for samples, prototypes and small production runs.

Hasco 3D printed the inserts in Stratasys' ultra-tough Digital ABS material using the Objet 500 Connex multi-material 3D production system. With a 3D printed mold insert taking only hours to produce, molders can make design modifications to the product at a fraction of the time and cost of conventional tooling methods.

"With time-to-market cycles shorter than ever and production quantities dropping, our customers are now looking for solutions that enable them to deliver prototypes quickly and cost-effectively," said Dirk Paulmann, Executive Vice President, Sales and Business Development at Hasco. "Compared with conventional metal or aluminum inserts, our new approach offers molders the flexibility to quickly produce and switch inserts, making them much more productive and profitable. Combining our longstanding heritage in moldmaking with Stratasys' pioneering expertise in 3D printing injection molds, this best-of-both-worlds technique is the future of prototype and low volume production," said Paulmann.

About the Author(s)

You May Also Like