Relocated Chinaplas hits new heights in 2018

The April show at Shanghai’s NECC laid claim to be the largest plastics show in the world in terms of area and exhibiting companies.

May 3, 2018

|

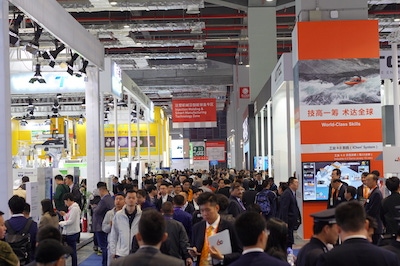

It was standing room only at Chinaplas, Asia’s and the world’s largest show in terms of exhibitors and floor space. |

The mammoth National Exhibition and Convention Center (NECC) in Hongqiao, Shanghai is indeed a sight to behold. The four-leaf clover-shaped complex is reportedly the world’s largest “single block building” with a total built-in area of a total construction area of 1.47 million square meters including 400,000 square meters of indoor area, which consists of 13 large exhibition halls and three small exhibition halls. The first Chinaplas in 1983 was held over an area of merely several thousand square metres.

And while Chinaplas 2018 didn’t quite pack out the entire venue, with an exhibition area exceeding 340,000 square meters – 40% larger than that of the 2016 edition in Shanghai – and around 4000 exhibitors, the show can now lay claim to being the largest in scale in the world. For comparison, the 2016 edition of the K Show in Düsseldorf, Germany hosted 3,293 exhibitors over 173,025 square meters of net exhibition space (the total area of Düsseldorf Messegelände is 261,817 square meters). K 2016 did attract 232,053 visitors over its eight-day duration, outnumbering the 180,071 that made the trek to Shanghai. Interestingly, Chinaplas continues to embellish its international credentials, with the 47,900 foreign visitors representing over 26% of overall attendee numbers.

Not surprisingly, solutions for the automotive sector were in abundance at Chinaplas given China’s position as the world’s leading vehicle manufacturer and the leader in adoption of new energy vehicles (electric and hybrid electric vehicles). Long fiber thermoplastic (LFT) pultrusion line manufacturer ProTec Polymer Processing is one company taking advantage of the growing market for lightweighting solutions in Chiba. Last year it delivered a 64 strand pultrusion line to Suzhou Hechang Polymeric Materials Ltd., which is developing LFT pellets using polypropylene (PP), polyamide (PA), acrylonitrile-butadiene-styrene (ABS) and polyester (PBT) resin matrixes, predominantly in combination with glass fiber reinforcements.

About the Author(s)

You May Also Like