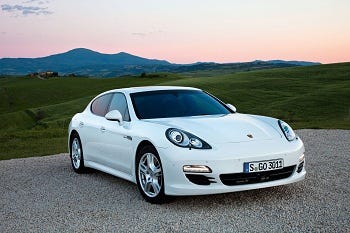

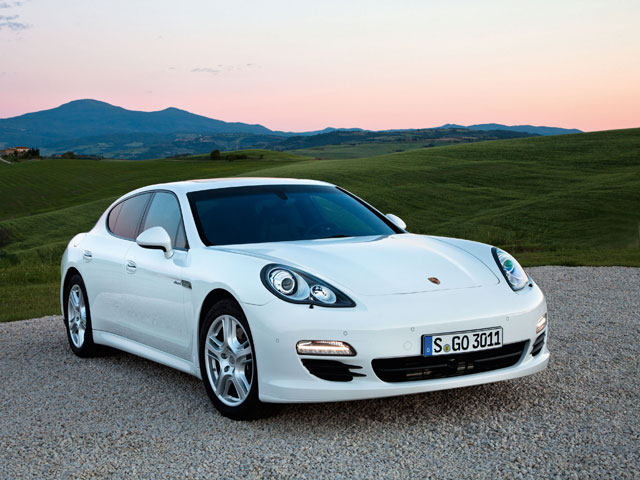

Diesel luxury car turns to melamine foam for acoustic and heat insulation

A melamine resin foam ensures the right sound effects under the hood of the Porsche Panamera Diesel. The foam is used for both sound and thermal insulation in the four-door Gran Turismo's engine compartment, transmission tunnel, and paneling near the engine.

April 30, 2012

A melamine resin foam ensures the right sound effects under the hood of the Porsche Panamera Diesel. The foam is used for both sound and thermal insulation in the four-door Gran Turismo's engine compartment, transmission tunnel, and paneling near the engine.

|

Melamine foam allows driver and passengers to enjoy Porsche engine sound minus less pleasing noise. |

Supplied by BASF (Ludwigshafen, Germany), Basotect's low density in addition to its good acoustic properties and high thermal resistance is what especially attracted developers from the Stuttgart-based automaker. Basotect is used to absorb sound in vehicles wherever there are high operating temperatures over an extended period of time, such as in the separating walls between the engine compartment and the car interior, engine hood paneling, engine proximity shells, and transmission tunnels.

Basotect is especially well-known for its outstanding acoustic properties. Thanks to its open-cell, fine foam structure, it has very good sound absorption values in the medium and high frequency ranges. Drivers and passengers in the Panamera can therefore enjoy the typical Porsche engine sound—without annoying accompanying noise. With a density of 9 kg/m3, Basotect is lighter than the conventional insulating materials generally used in engine paneling. This reduces both fuel consumption and CO2 emissions.

The foam's very high thermal resistance properties also played an important role in its selection as a material. Basotect offers long-term thermal resistance at 200ºC+. Jürgen Ochs, manager NVH Body (Noise, Vibration, Harshness) at Porsche, explains that: "With its 184kW/250 HP six-cylinder diesel engine, the Panamera's engine compartment is regularly subjected to temperatures of up to 180 degrees. Basotect withstands these extreme conditions."

Basotect can be used to make sophisticated 3D components and customized elements for very tight spaces. The melamine resin foam can be precision-processed by blade and wire-cutting as well as by sawing and milling—enabling dimensions and contours of customized components to be easily and exactly produced. Basotect is also suitable for thermoforming, although for this the foam has to be impregnated beforehand. Given these convincing material properties, Porsche is planning to use Basotect for future component developments as well. —[email protected]

About the Author(s)

You May Also Like