Hydraulic-assisted drive promises to almost double fuel economy

Forget about hybrid or electric drive. One day internal-combustion engine vehicles may be receiving a power boost from hydraulics. This could potentially save 45 percent on fuel consumption in urban traffic according to the system's developers, Peugeot Citroën and Robert Bosch GmbH (Stuttgart).

February 22, 2013

Forget about hybrid or electric drive. One day internal-combustion engine vehicles may be receiving a power boost from hydraulics. This could potentially save 45 percent on fuel consumption in urban traffic according to the system's developers, Peugeot Citroën and Robert Bosch GmbH (Stuttgart).

|

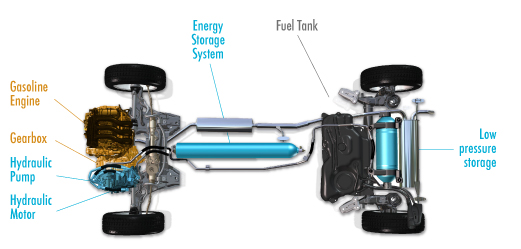

Hydraulic power assist set to boost fuel economy. |

The two companies are now planning to jointly develop a hydraulic hybrid powertrain for passenger cars essentially comprising two hydraulic units and their pressure accumulators.

The powertrain will allow the vehicle to be driven in three ways: the conventional engine-driven way, hydraulically, or by a combination of the two. At low loads, the internal-combustion engine can be run at a more economical operating status. When braking, the kinetic energy that would otherwise be lost as heat is converted into hydraulic energy and stored in a pressure accumulator. This energy can then be used to drive the car. In addition, driving off can be done purely hydraulically, and short distances driven without any emissions. The result is a potential average CO2 reduction of 30% in the new European driving cycle, and as much as 45% in a purely urban driving cycle.

In principle, this technology can be combined with any conventional engine but in an initial phase, it is to be used in the compact car segment, but it is also suitable for other passenger-car segments and light delivery trucks in urban traffic. This hydraulic-mechanical powertrain system results in a hybrid powertrain that is more cost-effective, robust, and service-friendly. In addition, it does not require any special infrastructure, and can be deployed anywhere in the world.

The technology works on the same hydraulic powertrain principles as those used worldwide by Bosch Rexroth (Lohr am Main, Germany) in various types of commercial and industrial vehicles. Bosch and PSA see great potential for adapting this technology to passenger cars.

About the Author(s)

You May Also Like