IML automation

December 11, 2008

|

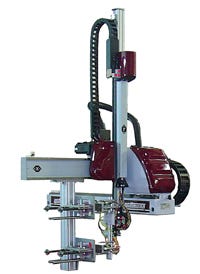

A new automated system for inserting labels into one- or two-cavity molds run on 90- to 275-ton machines at cycles down to 5 seconds has been introduced by Wittmann Inc. (Torrington, CT). A key component of its system is the company’s new W717 robot equipped with its R7 CNC control system engineered for easy sequencing and setup.

The W717 features a fixed kick-stroke frame that prevents interference with machine hoppers and blenders on smaller-tonnage machines. It’s also equipped with a servodriven vertical arm, providing up to a 47.2-inch stroke. Its horizontal axis can be manually adjusted to slide the entire robot to the side, either for safe and easy mold changes or for proper positioning after a mold change. Its pneumatically driven kick stroke also is adjustable for accommodating different mold thicknesses.

The robot’s EOAT comes equipped with an electrostatic label charger. Maximum label dimensions handled range up to 8 by 8 inches. The systems’ label magazine, mounted on its kick-stroke frame, provides a 1-hour production buffer. Repeatable label pickup by the robot is ensured by the label magazine’s spring-loaded end plate. And the magazine also allows for ergonomic horizontal loading of labels by the operator.

Label changeovers can easily be accomplished simply by changing the label magazine and tooling. So, fast system amortization can be achieved over a variety of production runs.

About the Author(s)

You May Also Like