In-mold assembly made more flexible with new rotary cube mold

If you have every seen a rotary cube mold in operation at a trade show or in an injection molding shop, you know how impressive these can be. These molds help processors take the "pellet-to-part" philosophy to an extreme as truly complicated multi-material parts exit the mold, ready for shipping.

August 23, 2011

But in life there is no free lunch (Ed. Actually we are offering you one in our Price Wise Challenge), and the price of these molds is very high, typically measured in the millions of dollars. Or at least the price always has been high in the past, which is why buyers of these molds usually are huge multi-national fast moving consumer goods companies requiring outputs of some parts in the hundreds of millions per year. But one mold maker, Zahoransky, says it has a new development that bests other rotary cube molds on output and flexibility, traits it says will help reduce the payback period for these molds.

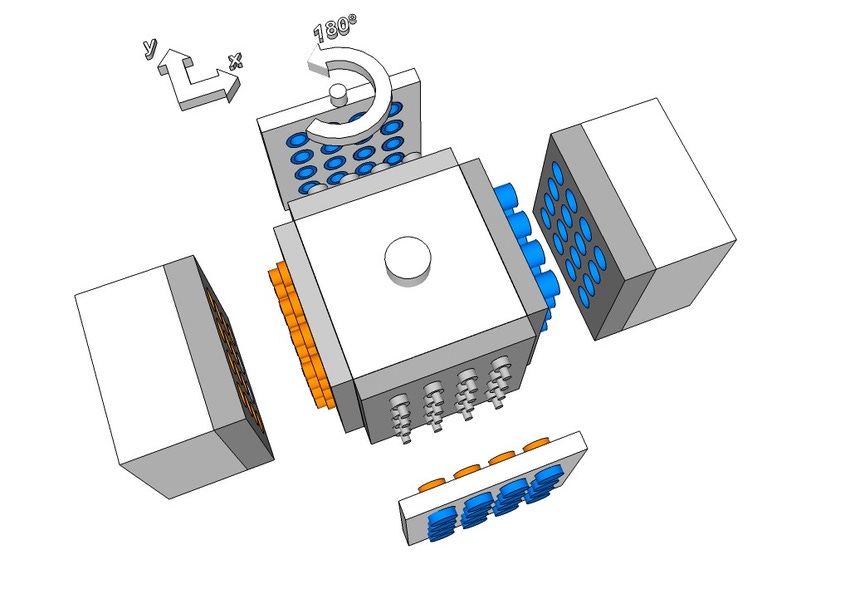

The company is calling its patented technology a TIM (Total Integrated Manufacturing) stack mold. Zahoransky is known both for its injection molds as well as its automation / assembly systems, and it seems to have combined these competencies in this new development. The TIM mold consists of two mold halves with an axial rotary cube, allowing two different parts to be made on a single mold.

During the Fakuma trade show in mid-October in Germany, Zahoransky (Freiburg, Germany) says it will run one of its TIM molds at the stand of plastics processing machine manufacturer KraussMaffei as part of a molding cell for push-pull beverage bottle closures. A 200-ton, two-color press will hold the 2 x 4-cavity tool. Three separate closures will be assembled inside the mold in each cycle, without an increase in machine cycle time, according to the mold maker.

The outstanding feature of this new injection molding system is the addition of two assembly platens placed outside of the mold. Complex assembly processes can be completed between these two platens, external to the molding machine; that's why Zahoransky claims processors realize no cycle time penalty for the assembly. In-mold operations have long been marketed as making good sense if a processor takes a total cost look at an entire process, but the 'time to payback' math will be even simpler if the assembly can be handled with no cycle time penalty.

Apart from assembly, potential functions include screw-connecting of parts or leakage tests of assembled subassemblies or modules.

The cube itself alternates its rotation, once to the right and once to the left, with each turn measuring 90°. The moldings are transferred after each injection step to one of the two assembly units, with the parts injected in the second station mechanically interconnected with the parts already transferred on the assembly platen.

The assembly platens can move in different planes as required. For instance, they can be designed to traverse on a X-Y axis; 2) turning by 180°, assembling and ejecting; 3) turning, assembling, testing and ejecting; 4) assembling, fitting with another external part, testing, ejecting.

In contrast to conventional cube techniques, the complexity of the mold is reduced because of that external assembly unit, and as a result the mold maker says the payback period for the mold is much shorter than with molds made in the past that offered in-mold assembly.

TIM allows the mold structure to be clearly separated from the mold cavities. Regardless of assembly direction or assembly alignment, TIM offers the option of producing different products in a single mold, cutting the investment required when changing models or patterns. The actual structure of the mold remains, with only the cavity platens being exchanged.

Zahoransky predicts typical applications of the new system will be found in the packaging sector or in the production of parts for medical engineering.

About the Author(s)

You May Also Like