Chromium-free plating plastic solutions tackle impending legislation

September 21, 2017 is a critical date for automakers if they employ chrome-plated components in their vehicles. This is the sunset date set by REACH legislation inb Europe to eliminate the use of chromium trioxide. Thankfully, materials and machinery suppliers are already working on solutions to enable the shiny metal finish to be reproduced.

December 10, 2014

September 21, 2017 is a critical date for automakers if they employ chrome-plated components in their vehicles. This is the sunset date set by REACH legislation inb Europe to eliminate the use of chromium trioxide. Thankfully, materials and machinery suppliers are already working on solutions to enable the shiny metal finish to be reproduced.

For example, Dow Electronic Materials has developed the chromium-free Ecoposit etching solution to replace chromic acid etching used in the pre-treatment of acrylonitrile-butadiene-styrene (ABS) and polycarbonate (PC)-ABS in the plating-on-plastics (POP) industry.

|

Electro chromium plating is on the way out, but alternative processes, such as this PVD-based one, are emerging for plastics decoration. |

The selection of a replacement etchant species was reportedly the result of many years of research to find a candidate and associated process parameters, with the stability, performance and process window to substantially fit into existing POP equipment. Dow's novel Ecoposit Etch is an integral part of the Ecoposit CF-800 chrome-free pre-treatment, utilizing the stable and regenerable manganese (Mn) III species to replace the incumbent hexavalent chromium oxidant. Dow has been granted a US patent (8603352 B1) for this chrome-free etching process, laying the platform for the move towards commercialization and the road to the elimination of hexavalent chromium in POP pre-treatment.

The building of industrial performance data in different market segments has begun in order to provide pathways for customers to test and qualify Dow's technology and implement in advance of the 2017 deadline.

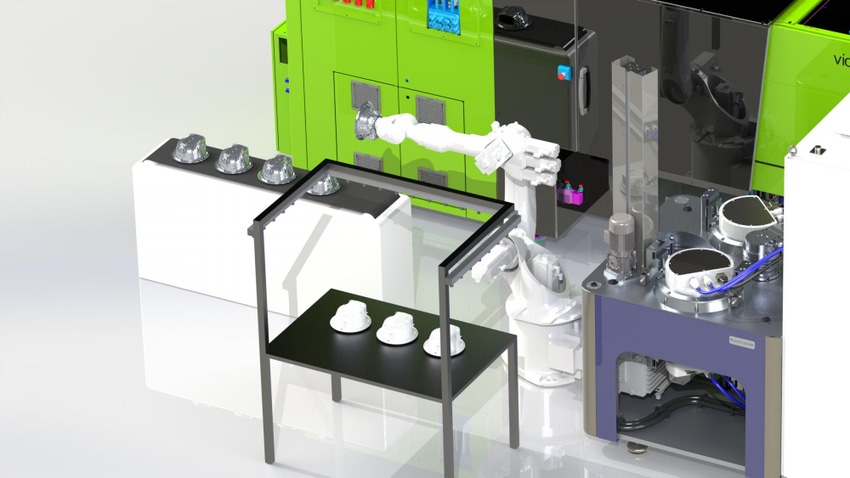

In a related development, an integrated plastic injection molding and PVD (plasma vapor deposition) vacuum metallization process is now qualified for automotive interior decoration. German plastic component manufacturer Varioplast GmbH (Ötisheim) uses Plasticoater PVD equipment from Impact Coatings AB (Linköping, Sweden) for integrated manufacturing of parts to the new Volkswagen Passat. The technology was earlier displayed at the recent Fakuma show.

The short-cycle PVD system reportedly enables fully integrated and automated production cells with injection molding and PVD metallization. This Lean PVD production solution reduces costs and lead-times, and improves quality, compared to traditional metallization methods. Adding UV lacquering to the production line, Lean PVD also provides a very cost-efficient and chromium-6-free alternative to chromium plating on plastic.

Varioplast uses the solution for its Instantchrome inline metallization process that is offered for both decorative and functional finishing of molded plastic. "The Instantchrome inline metal coating process developed by Varioplast, and based on PVD, is ideally suited to our in-house process chain strategy and in the future shall replace electro chromium plating at our plant" says Michael Däbritz, CEO at Varioplast.

You May Also Like