July 1, 2001

From toothbrushes to pens, from coffee makers to baby products, the consumer products market encompasses a broad range of goods. Yet, all have one thing in common—the need to keep up with trends in color, style, and technology. With that goal, however, comes the biggest challenge for molders in this market. Trends come and go quickly, shortening product life cycles. Customers, in turn, put pressure on molders to bring new product designs to market quickly.

One company has found success in the speed-to-market battle by developing what it calls early involvement engineering. At Plastech Corp. (Forest Lake, MN), a contract manufacturer with clients in the consumer products market, engineers are directly assigned to the sales group and work side by side with account managers and client engineers to develop new product designs.

According to David Brentz, senior vp of sales and marketing at Plastech, the concept saves valuable time by catching problems early on. "It speeds up the development of a new part by eliminating some of the problems that a client's engineering group might run into, either in the realm of tooling or molding," he says. "Basically, we try to bring expertise in those two areas so we can speed up the cycle."

Consumer market consumption of key resins, million lb |

|

Polypropylene |

Polystyrene |

LD polyethylene |

HD polyethylene |

Polycarbonate |

Other thermoplastics |

ABS/SAN |

Nylon |

Consumer market totals |

Source: The Freedonia Group; www.freedoniagroup.com |

Customer Integration

Shorter product life cycles may be the biggest challenge in this market, but one of the biggest trends is the increasing use of electronic data interfaces (EDI). Brentz says molders not participating in some form of EDI should seriously consider changing their mindset if they wish to compete in this trendy market.

"To play with the larger manufacturers you need to have EDI. I definitely think that's the direction things are going," Brentz says. As a contract manufacturer, Plastech communicates using whatever methods or technology its clients request, and EDI is among the most common. The company was a beta site for a major manufacturing company about 10 years ago and now EDI is integral to its operations. In 2000, more than 60 percent of Plastech's transactions were handled via EDI, up from 40 percent in 1999. Says Brentz, "We can't afford to have a bunch of people sitting on telephones transcribing information anymore."

Another way to play with the big companies in this market is to offer services that "don't fit their core competencies," says Brentz, referring to manufacturers that are not vertically integrated and prefer contracting out services. This is where some of Plastech's secondary operations have come into the forefront, offering contract manufacturing services that other companies are willing to divest.

The "G" Word

Of course, one can't speak of the consumer products market without referring to the reality all markets must eventually face: global competition. Plastech has developed East Asian tooling sources, giving its clients more alternatives to speed time to market and cut costs. Though East Asia has a notable hold on the consumer electronics market, Brentz looks to Latin America as the dominant force for all other types of consumer products, partly for its geographic location. "Plastic parts are very sensitive to shipping so the larger the part, the less it can be transported," he says. "As parts get larger, the East Asian competition starts losing some of its competitive edge."

As for the market's outlook over the next year or so, Brentz points to the tremendous growth and capacity along the U.S-Mexico border over the last four to five years, noting the numerous molding operations in the southern tier of the U.S. and those that have sprung up with some kind of joint partnership in northern Mexico. He believes that capacity has the ability to turn into an overcapacity if the U.S. market continues to soften. "I see that developing into a capacity glitch for our industry. How long that will last—those things can turn relatively quickly—I don't know. But there is some overcapacity and that puts pricing pressure on everybody."

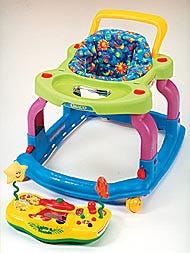

Safety and toughness in infant walker

Safety and toughness in infant walker

• Application: See-through window tray in a walker for infants.

• Material used: Durastar 2010 PCTA (Eastman).

• Manufacturer/designer: Graco Children's Products (Elverson, PA).

• Functionality: This mobile entertainer for children, also known as a walker, must withstand the continuous impact of a toddler bumping into walls and banging on the walker's tray.

• Manufacturing details: DuraStar 2010 was reportedly easy to process and the part readily released from the mold.

• Challenges/innovation: Safety is always an issue when designing children's toys. Graco Children's Products incorporated the window into the tray, which enables the child to see his or her feet and the floor. To withstand impact without cracking or shattering, the window was designed as a tongue and groove part with a few fasteners. Graco needed a material with the strength and clarity of polycarbonate but that was more cost effective because of the quantities needed. The company conducted impact resistance tests using DuraStar and selected 2010, a high-impact-resistant material that includes a mold release. Durastar's long-term clarity and resistance to household cleaners made it ideal for the walker. In addition, the polymer maintains its clarity without yellowing or hazing.

Eastman Chemical Co., Kingsport, TN

Phone: (423) 229-4853

www.eastman.com

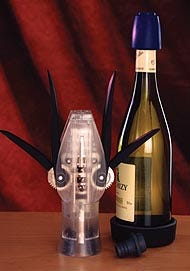

TPE compounds suit wine serving needs

TPE compounds suit wine serving needs

• Application: A line of wine accessories.

• Materials used: Various grades of Evoprene TPE (AlphaGary).

• Manufacturer/customer: Vacu Vin BV (The Netherlands).

• Functionality: Three products were manufactured to make wine serving cleaner and easier. The Wine Server prevents spillage when pouring a bottle of wine, the Bottle Coaster holds wine bottles and protects table surfaces, and the Winemaster corkscrew uncorks bottles without manual twisting.

• Manufacturing details: The Bottle Coaster is comolded with Evoprene and polypropylene.

• Challenges/innovation: The Evoprene line of compounds has good processing characteristics, food contact approval, and a history of successful use in the wine industry—all crucial requirements for making wine serving accessories. The Wine Server is molded from a hard Evoprene grade that is rigid enough to fit neatly over the bottleneck and provide a comfortable tactile grip when pouring wine to prevent drips or spills. The Winemaster corkscrew was molded using a soft Evoprene compound designed to grip the bottleneck as the cork is being removed. And by comolding the Bottle Coaster, which doubles as a drip catcher, a nonmarking, nonslip base is produced, as well as a soft grip for holding the bottle.

AlphaGary Corp., Leominster, MA

Phone: (978) 537-8071

www.alphagary.com

Resin gives users a soft touch

Resin gives users a soft touch

• Application: Soft-touch grip of the Reflex pen.

• Material used: Multi-Flex TEA 1004, a 70 Shore A TPE based on SEBS chemistry (Multibase).

• Customer: Parker Pen Products (Janesville, WI)

• Functionality: The soft-touch grip of the Reflex pen improves ergonomics while writing.

• Manufacturing details: The Multi-Flex TEA grade reportedly provides a wider processing window than polyurethane, which was previously used for this application. Molds can be designed with fewer gates and weldlines, eliminating potential weak points. Combining flexible and rigid materials in a single molding process is said to help increase precision as compared to mechanical or adhesive assembly.

• Challenges/innovation: Parker wanted a material with good resistance to abrasion and low swelling when used in contact with oily materials. The low and high temperature resistance of Multi-Flex 1004, in addition to its lower hardness and good processability, made it appropriate for the ballpoint pen's soft-touch grip.

Multibase Inc., Copley, OH

Phone: (330) 769-2709

www.multibase.com

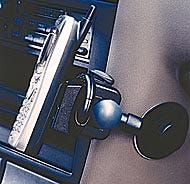

MPR provides more stable swivel

MPR provides more stable swivel

• Application: Swivel feature and locking mechanism in a mobile phone mount.

• Material used: Alcryn melt processable rubber (MPR, Advanced Polymer Alloys).

• Manufacturer/customer: Pro.Fit International (Eagan, MN).

• Molder: Thermoplastic Design Inc. (St. Croix Falls, WI).

• Moldmaker: Meehan Tool & Engineering Inc. (Roseville, MN).

• Designer: Worrell Design (Eden Prairie, MN).

• Functionality: The swivel and locking mechanism are designed to enable safe, hands-free mobile phone operation without moving or dislodging the mount.

• Manufacturing details: Alcryn MPR does not require vulcanization, predrying, or any compounding prior to processing. Scrap can reportedly be recycled repeatedly with minimal detrimental effect on performance or appearance.

• Challenges/innovation: Pro.Fit needed a phone mount that enhanced driver safety without compromising the integrity of the automobile's interior. Using Alcryn MPR, the new design provides the right hardness and proper friction between the plunger and the ball to hold the weight for this application. A cleaner overall look is also achieved as there are no flow or knitlines resulting from the use of Alcryn. The lack of odor and the numerous coloring capabilities provide additional benefits; Pro.Fit intends to introduce colors in gray, light blue, and tan, in addition to the original charcoal/gray.

Advanced Polymer Alloys, Wilmington, DE

Phone: (302) 478-8989

www.apainfo.com

Tough, clear plastic clicks for ballpoint pen

Tough, clear plastic clicks for ballpoint pen

• Application: Clear plastic cap of Pentel BK-92 ballpoint pen.

• Material used: Eastar PETG copolyester 6763 (Eastman).

• Customer: Pentel of America Ltd. (Torrance, CA).

• Functionality: The cap produces an audible click when replaced on top of the pen.

• Manufacturing details: The cap measures approximately 21/2 inches long, 1/2 inch in diameter, and weighs approximately 5g. It is not uniform in thickness throughout its length. A long plastic clip is an integral part of the design, as well as an undercut rib that produces the audible click.

• Challenges/innovation: In addition to producing an audible click when replaced, the cap needed to have good clarity and gloss, as well as strong surface hardness to resist scratching. It also needed to be stiff enough to maintain tension in the cap's long plastic clip, yet resilient enough to resist breaking when flexed. Eastar PETG met all of those requirements. Moldability was another consideration; the undercut on the core pin makes it difficult to remove the molded cap without damaging the undercut area. A proprietary technology was used to create a new molding system. The material's moldability allowed it to meet these demands. In addition, Eastar PETG copolyester 6763 has good resistance to a variety of chemicals, which is helpful in this application since writing instruments are subjected to elements such as natural skin oils and hand lotions.

Eastman Chemical Co., Kingsport, TN

Phone: (423) 229-4853

www.eastman.com

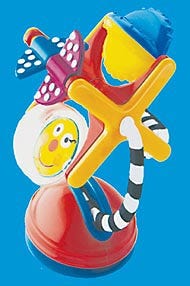

Material problem solved for a baby toy

Material problem solved for a baby toy

• Application: Fascination Station, a play station for infants six months and up.

• Materials used: Dynaflex G2701 TPE(GLS) and PP.

• Customer: Sassy Baby Products Inc. (Kentwood, MI).

• Functionality: The Fascination Station offers multiple features for playing and is two toys in one. It can be attached with a suction cup base to a table or high chair tray where the baby can spin, flip, and twirl it, or it can be removed from the base for use as a rattle.

• Challenges/innovation: Dynaflex is overmolded onto polypropylene. Sassy approached GLS to assist in solving a materials problem. The soft material previously used in the handle was not adhering to the substrate effectively. The toy design required that a soft-touch material be overmolded onto a polypropylene handle with an alternating black stripe pattern. The material needed to be easily colored, nontoxic, and hypoallergenic. It also had to pass tear-resistance tests to withstand infant teething and gumming. Dynaflex passed all tests and is reportedly easy to color and has good bonding properties. The durometer of the material is a relatively soft 65 Shore A.

GLS Corp., McHenry, IL

Phone: (815) 385-8500

www.glscorp.com

You May Also Like