Research Turns Plastic Waste into Biodegradable Silk

Is plastic-eating, silk-producing bacteria a new ally in the fight against waste? A new $500,000 grant for Rensselaer Polytechnic Institute should answer that question.

Solutions to big problems can spring from little things. In research at Rensselaer Polytechnic Institute in Troy, NY, a microorganism that digests common petroleum-based plastic waste and yields a biodegradable plastic alternative represents a new solution to an on-going problem.

With the support of a substantial new National Science Foundation grant of $500,000 for the project, a team of engineers from Rensselaer Polytechnic Institute will explore this potentially transformative idea entitled Microbial Upcycling of Petrochemical Polymer Waste into High Value Protein-Based Polymers for a Circular Economy.

“We have all of this plastic pollution in the environment that comes from all of this plastic that we use on a daily basis, most of which is based on petroleum feedstocks, which are based on molecules that can’t degrade naturally in the environment,” says Helen Zha, an assistant professor of chemical and biological engineering at Rensselaer, who is leading this research project.

Zha and her collaborators will explore whether a genetically engineered bacteria would be capable of breaking down petroleum-based plastic waste that could then be used as energy to produce artificial silk, a biodegradable protein that behaves much like traditional plastic.

Provided over a two-year period, the NSF grant will allow RPI to demonstrate proof-of-concept at a small scale.

“The grand-funded research began in September, though we performed some preliminary studies earlier this year,” Zha says. “We’re now at the bench-top level and are working towards pilot scale-up.”

It’s currently a batch process.

“However, there may be potential for developing a continuous process in the future, in conjunction with other research occurring in our lab,” Zha points out. “We also hope to explore pilot production at 20 to 30-Liter scales within the project timeframe.”

|

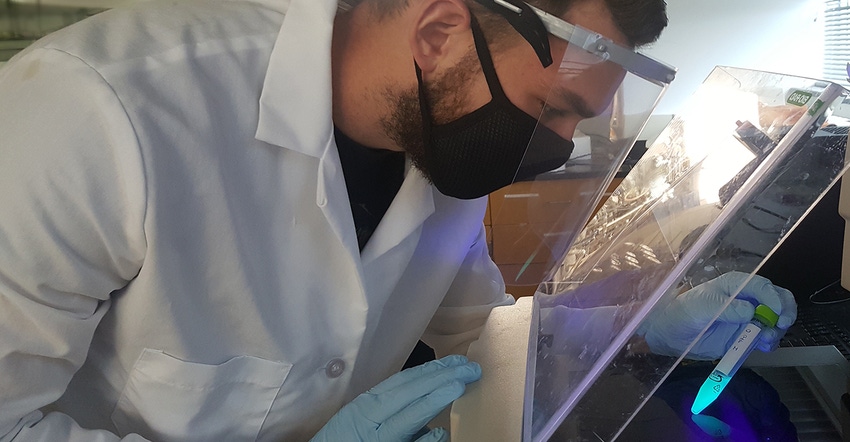

Graduate student Alex Connor in a lab at RPI's Center for Biotechnology and Interdisciplinary Studies. |

Into unexplored territory.

“The use of metabolic engineering approaches for plastic waste degradation and its conversion to higher value chemicals such as biopolymers is an underexplored area of research,” says Mattheos Koffas, a professor of chemical and biological engineering. He has previously established a number of microbially-based processes and now joins Zha in this research. “Our collaborative effort will provide more sustainable and environmentally friendly methods and materials.”

According to Zha, a barrier to using silk as a replacement for traditional plastic is that it’s hard to produce from nature in large quantities. Designing and creating a new bacterium that can manufacture artificial silk could be a valuable solution.

“Our research develops genetically modified bacteria capable of producing recombinant silk protein by metabolizing waste plastic,” Zha explains. “At some point, we as a society should be transitioning to using plastics that not only come from nonpetroleum-based sources, but can also completely degrade into something that goes into the natural environment.”

If you’re familiar with the term GMO, this is a similar process.

The research is presently focused on polyethylene, which Zha calls a “major source of global plastic waste. However, our technology also has the potential to be compatible with other common plastics.”

There are various potential end markets for the artificial silk.

“While textiles are one possibility, other interests include replacements for single-use plastics such as packaging and wraps or materials for biomedical applications,” says Zha. “While some of the materials produced may replace silk, the intention of the project is to develop a microbial system that can produce silk materials with tunable properties that may suit a diverse range of applications.”

Molecular design.

"How to optimize the molecular architecture and microstructure of artificial silk is a fascinating design problem that nature has perfected over hundreds of millions of years, yet we have just started to piece clues together,” says Yunfeng Shi, an associate professor of materials science and engineering, and another grant collaborator.

This unique challenge requires a cross-disciplinary approach, bringing engineers together from across departments.

“This forward-thinking, innovative idea is exactly the type of environmentally friendly and sustainable solution CBIS faculty are focused on developing,” says Deepak Vashishth, the director of the Center for Biotechnology and Interdisciplinary Studies (CBIS) at Rensselaer, of which Zha and Koffas are members.

The RPI team is also partnering with Guohong Mao, the associate director of Conagen, a biosynthesis and biomanufacturing company. It seems a natural choice; according to the company’s website, “Conagen innovates and develops synthetic biology solutions for supporting global partners across a spectrum of current and developing markets. Our bio-manufacturing capabilities, coupled with extensive platforms of enzymes and microorganisms, gives us the edge in commercial biotechnology. Nature is our inspiration for designing metabolic pathways, improving production organisms, and optimizing production processes."

About the Author(s)

You May Also Like