Do we really want solar panels to be manufactured in the United States?

The Trump administration has slapped a tariff on imported solar panels to incentivize domestic production. But the manufacturing process and the materials used to make the panels raise a host of environmental issues.

January 29, 2018

Samsung will begin building washing machines in its new plant in Newberry, SC. LG is putting a plant in Tennessee to manufacture its washing machines. Good timing given the tariffs on imported washing machines that are being imposed, something that just might help drive foreign manufacturers to make more products in the United States for this market.

|

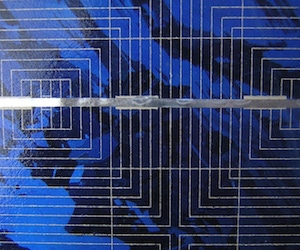

Image courtesy Golo/flickr. |

A similar tariff has been placed on foreign-made solar panels, which are subject to duties as high as 30%. One report in Bloomberg noted that some 80% of all solar panels are imported. First Solar, headquartered in Tempe, AZ, is the only large-scale U.S. solar panel manufacturer; however, its technology is geared toward utility-scale projects, not residential rooftop use.

If the goal of these tariffs is to drive manufacturing back to the United States, then we have to ask the question: Do we really want solar panels to be manufactured in the United States?

While green energy is promoted as “clean” energy, that isn’t really the case with solar panel manufacturing. Solar energy may be a way to reduce our dependence on fossil fuels and cut CO2, but those who promote this “green” energy do not go into details about the manufacturing process or the materials used to make solar panel components.

A number of years ago when solar energy became a serious discussion, I recall reading an article explaining why the Environmental Protection Agency (EPA) would not approve domestic manufacturing of solar panels: The toxicity involved is too harmful to the environment. Even if the EPA were to approve solar panel manufacturing, the regulatory approval process for siting a solar manufacturing plant could take years. China and other Southeast Asia countries were the only option for large-scale production of solar panels.

Some of the toxic materials used in the manufacture of solar panels are cadmium telluride, gallium arsenide, copper indium selenide and silicon tetrachloride, a byproduct of producing crystalline silicon, rated as “highly toxic” in the April 25, 2017, issue of Sciencing. The low price of solar panels made in China “relied on China’s notoriously poor environmental protections and the dangerous working conditions in its mines and factories,” noted a Sept. 22, 2014, blog post, "The True Cost of Chinese Solar Panels," on the Alliance for American Manufacturing website.

The U.S. solar industry is mostly composed of installers rather than manufacturers primarily because we have the Occupational Health and Safety Administration along with the EPA to prevent health hazards and environmental disasters.

A study from Environmental Progress warns that toxic waste from solar panels now poses a global environmental threat. Between the manufacturing process and end-of-life issues, solar panels produce 300 times more toxic waste per unit of energy than nuclear power, it said.

The Solar Energy Industries Association disagrees with that assessment, and claims that solar panels are made of “easy-to-recycle materials” that can be reused. However, in an article in the June 28, 2017, edition of National Review, “Solar-Panel Waste: Environmental Threat from Clean Energy,” writer Julie Kelly notes that solar panels are “intricate to disassemble and recycle” given the wide array of metals, plastics and other components that comprise these panels. “Japan is already scrambling for ways to reuse its mounting inventory of solar panel waste, which is expected to exceed 10,000 tons by 2020,” a number that is expected to climb dramatically over the next two decades as more panels reach the end of their 25-year lifespan, Kelly noted.

Given what we know about the hazardous manufacturing processes of solar panels, it’s perhaps better that we pay the tariffs, which would seem to result in lower overall costs, than the environmental and human costs of manufacturing them in the United States. However, consumers need to be reminded of the huge price people in China, Taiwan, the Philippines and Vietnam pay for their “green” energy, which perhaps isn’t so green after all.

About the Author(s)

You May Also Like