Primer on conductive plastics: Things to consider as you specify these materials

Conductive plastics are developed by compounding thermoplastics with electrically conductive materials such as carbon or steel fibers, carbon nanotubes (CNTs) or graphite, and other additives to enhance the dispersion of the conductive materials into the polymeric matrix. The result is to give conductive properties to some plastics that normally are isolators.

November 18, 2010

Conductive plastics are developed by compounding thermoplastics with electrically conductive materials such as carbon or steel fibers, carbon nanotubes (CNTs) or graphite, and other additives to enhance the dispersion of the conductive materials into the polymeric matrix. The result is to give conductive properties to some plastics that normally are isolators.

[Ed. Note: Luis Roca, director of the compounding department at Spain's Aimplas, the Technological Institute of Plastics in Valencia, was kind enough to share this report on conductive thermoplastics. We have edited it only slightly for formatting purposes.]

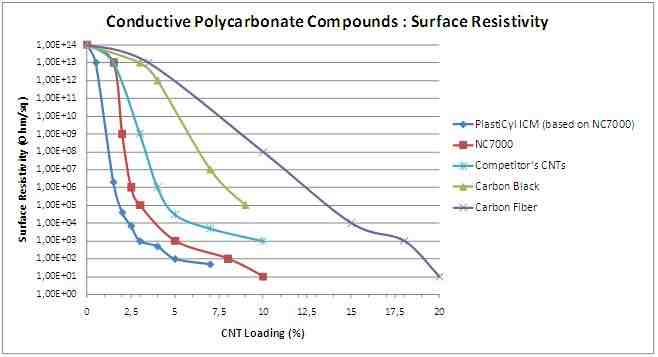

A wide range of electrical properties can be achieved in the final composite depending on the added percentage and the conductive material type. Also different applications can be reached, see Figure 1:

|

Figure 1 Polycarbonate Resistivity obtained with different conductive fillers (courtesy of CNT supplier Nanocyl)

A compound's resulting electrical properties are limited due to:

Viscosity: if the electrical requirements are very high (very low resistivity), a high volume of conductive fillers is required. Therefore, the viscosity of the mix will be increased dramatically.

Mechanical properties: the addition of fillers will enhance a plastic's electric properties but will decrease some important mechanical properties, such as impact strength, that are crucial for, for example, protective cases for electric devices - and these are some of the most important applications for conductive plastics materials.

Cost: usually, conductive fillers are relatively expensive materials. The higher the electrical conductivity, the higher the price of the final product.

Processing: depending on how well the conductive plastics are processed, better or worst electric properties may be obtained. The processing can be divided in two steps: compounding, and then injection moulding or extrusion, when a final part or some profile with the final properties is obtained.

These four main aspects have to be taken into account to obtain the best electric properties at the lowest cost without affecting mechanical and rheological properties.

During compounding, the quality of the mix will depend on how well the conductive fillers have been dispersed in the matrix material. To obtain the most homogeneous compound, two different mixing steps have to take place (Figure 2):

Figure 2 Mixing steps, dispersion and distribution

Dispersion: This first step consists in generating the necessary flows to break the cohesive forces that keep the solid (conductive filler) together; the result of dispersion will be a decrease in particle size. During dispersion agglomerate are broken. Dispersion is always relative to shear capacity and dependant on design of extrusion screw flights.

|

Distribution: This second step of compounding creates a suitable flow to homogenously spread the conductive particles obtained during dispersion across the polymeric matrix. Distribution is related to the quality of the mixing and the use of more gentle screws.

With a low particle size and with very good particle distribution, the contact surface between the plastic and the conductive filler will be higher and the properties better.

Co-rotating twin-screw extruders remain the most widely employed type of equipment for compounding this type of product because of their versatility and ability to be used for any filler and plastic in varying throughputs. The main advantage of this machine is the modularity of its barrels and screws as both can be modified to optimize the machine for the chosen filler-polymer system.

When modifying the screw configuration, the screws selected can be more or less dispersive or distributive. Also, the side feeding position can be moved forward for feeding of fillers that are shear or heat sensitive to avoid breakage or thermal degradation.

To obtain a good compound, you need to consider:

Throughput: Increasing or decreasing the throughput can modify the shear, which will affect the melt.

Screw speed: This will affect the shear rate as well as the throughput.

Screw configuration: This is the main determinant for successful compounding. Screws are divided mainly into two mixing zones: a dispersive one, to break the agglomerates, a distributive one, to create a homogeneous mixture. The guidelines to work with conductive fillers in terms of screw design can vary strongly depending on the fillers; for instance fibers [stainless steel, carbon fibers or carbon nanofibers (CNF)] require a more distributive screw so that fibers are not broken, which would result in a loss of properties.

Alternatively, working with carbon blacks or CNTs requires a more dispersive screw to break the agglomerates or to unwind the CNT bundles.

Which formulation to choose?

The percentage and type of conductive filler has a direct effect on the conductivity of a compound. Unfortunately, but typically, the most effective conductive filler is the most expensive one. Usually suppliers of the fillers can offer a compounder or plastic processor guidelines on the amount of conductive fillers required to create a compound with the desired electrical properties as well as some guidelines to process them.

The most significant characteristic for the conductive fillers is the aspect ratio. A very high aspect ratio (such as with CNTs) will give plastics very good electric properties at low percentages (1-3%). Stainless steel fibers (SSF) provide better electrical properties than CNTs at similar percentages and furthermore allow coloring as opposed to CNT, CNF or carbon fibers. SSF also provides good electro-magnetic impulse (EMI) shielding properties, making compounds with this type of filler suitable to protect electric devices from electromagnetic interference.

If your application requires exceptional mechanical properties as well as good conductivity, it would be necessary to work with carbon fiber at loadings close to 30%. In this case, nanofillers can be a good alternative, as you will not require as high of a loading percentage to reach comparable mechanical properties.

On the other hand, conductive fillers with low aspect ratios, such as carbon blacks, will need loading percentages a multiple of that required with CNT to reach similar conductivity. This improved performance can be traced to CNTs' length compared to carbon black. However, newly developed grades of carbon black can provide solid conductive properties at loadings of about 10%.

It is possible to purchase highly conductive carbon blacks or special graphite that provide good electrical properties; depending on the polymer matrix, these must be mixed at loadings close to 50 % to reach conductivity of circa 25 S/cm. The cost of these fillers is reasonable.

Good Electrical Properties: Range of application

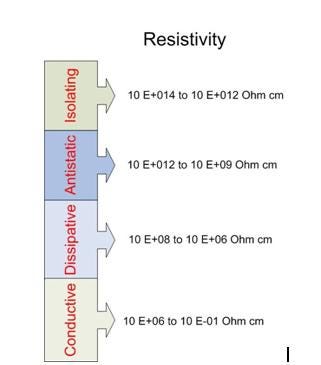

As the composition of the conductive plastics can be easily modified during compounding, it is possible to "dial in" an exact formulation to match the requirements for each application. Three main properties could be distinguished regarding conductive plastics: Antistatic, dissipative or conductive plastics, as shown in Figure 3:

|

Figure 3 Different levels of resistivity in plastics

The freedom to formulate allows the compounder to create some material fully exclusive to the customer requirements trying to cover all the plastic properties from the entire points of view: mechanical, thermal and especially electrical. Our work shows that conductive fillers can be successfully compounded into any thermoplastic.

The main applications for conductive plastics are items where some of the properties described in Figure 3 are required. Usually conductive plastic materials tend to replace metals in:

Electromagnetic interferences shielding applications (low or high shielding effectiveness) consisting of cases or boxes to protect electric or electronic devices from outside interference.

Electrostatic discharge or dissipative properties / electrostatic painting. These applications are most common in automotive and electronic applications.

Case studies we have researched were part of a European project called Polycond (www.polycond.eu) in which AIMPLAS served as technical coordinator, under the Framework Program 6 (successful use of conductive plastic materials) to obtain good EMI shielding and ESD properties and replace coatings and older conductive fillers with new ones, and create hybrid composites to find synergies between these. These new materials are property of the consortium and the compounders that where involved in this project, who have permission to market the materials developed.

In order to summarize the information generated during this 4-year project, another project under the lifelong learning program was created, called iPolycond (www.ipolycond.org). The objective of this is to create a book that will help the producers, mainly molders, to know more about these materials and the ways to process them. AIMPLAS is also working in this project and will complete the chapters of producing and designing with conductive plastic materials.

About the Author(s)

You May Also Like