Seal allows leak-free processing of low-viscosity materials

A new patent-pending seal for piston-type screen changers and divert valves is designed for leak-free processing of low-viscosity materials, such as hot melt adhesives (HMA) and cleaning solvents such as, but not limited to, acetone, toluene, hexane, and heptane. The new PSI-Polymer Systems Inc.'s (Conover, NC) seal is capable of operating at temperatures up to 520°F.

September 14, 2011

A new patent-pending seal for piston-type screen changers and divert valves is designed for leak-free processing of low-viscosity materials, such as hot melt adhesives (HMA) and cleaning solvents such as, but not limited to, acetone, toluene, hexane, and heptane. The new PSI-Polymer Systems Inc.'s (Conover, NC) seal is capable of operating at temperatures up to 520°F.

PSI received a U.S. patent (No. 7,147,774 B2) for a segmented seal design in early 2007. This latest seal is designed to work with discontinuous and continuous piston-type screen changers and polymer divert valves. PSI will show the new patent-pending seal design installed in a continuous screen changer at NPE 2012.

PSI-Polymer Systems supplies polymer filtration equipment, gear pumps, static mixers, divert valves, and engineered system solutions for the plastics extrusion, polymer processing and recycling.

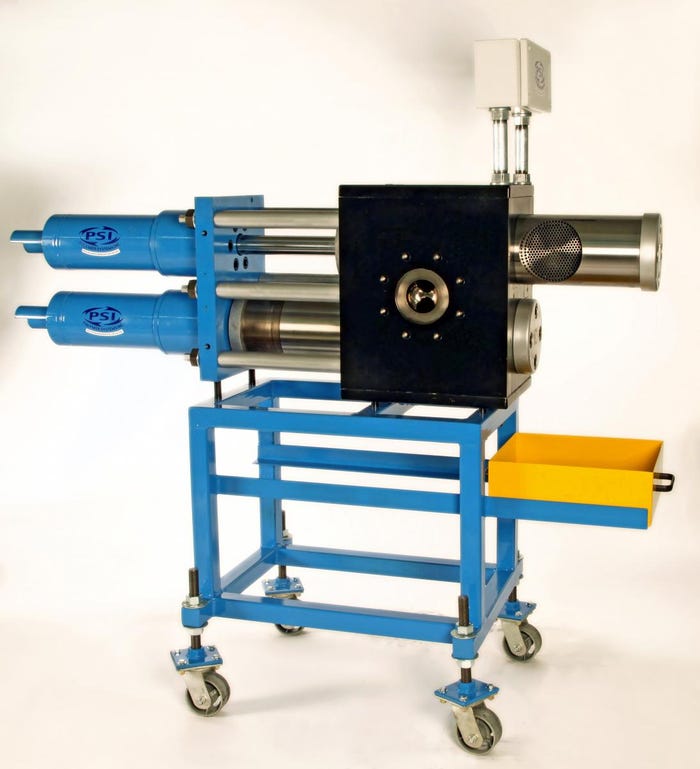

PSI Polymer Systems screen changer

About the Author(s)

You May Also Like