Toy designers choose recycled materials

Toy manufacturing has changed thanks to the Consumer Products Safety Improvement Act. For one thing, designers are coming up with creative toys from compliant materials.Every January or February, toy designers and manufacturers gather in New York to introduce upcoming product lines at the Toy Industry Assn.’s (TIA; New York, NY) Toy Fair trade show. This year, seminars during the show centered around the new regulations that took effect five days before the show opened.

March 16, 2009

Toy manufacturing has changed thanks to the Consumer Products Safety Improvement Act. For one thing, designers are coming up with creative toys from compliant materials.

Every January or February, toy designers and manufacturers gather in New York to introduce upcoming product lines at the Toy Industry Assn.’s (TIA; New York, NY) Toy Fair trade show. This year, seminars during the show centered around the new regulations that took effect five days before the show opened.

|

The Consumer Products Safety Improvement Act (CPSIA) of 2008 that kicked in on Feb. 10 mandates toy safety standards and requires that all children’s products must be tested for lead content, whether toys, books, or clothing. The law applies not just to new toys, which has a huge impact on smaller toy shops and consignment stores, and the manufacturers that supply the items. The Consumer Product Safety Commission administers the law, which can only be changed by Congress, and allows state attorneys general to take civil action against violators. Failure to comply can result in hefty fines and even jail time.

While many retailers and manufacturers believe the regulation may have good intentions, albeit with a difficult, expensive compliance process, consumers are increasing their awareness of potentially risky toys and seeking out eco-friendly products. Market research conducted on behalf of the TIA identified eco-awareness as one of five key challenges to be addressed by toy manufacturers selling into North America.

It’s good to use wood

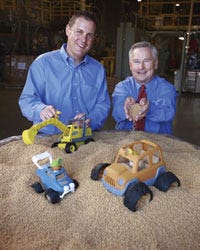

Many toy manufacturers have already been developing toys that are not only compliant, but also award-winning and popular with kids. Wood-plastic-composite vehicles from Sprig Toys Inc. (Fort Collins, CO) topped online retailer Firebox.com’s 2008 holiday season children’s gift list, and were also awarded the Oppenheim Toy Portfolio Platinum Award for 2009.

The company started when a group of toy designers, who had been successful in careers with top toy manufacturers, saw the environmental impact of toy manufacturing and decided to start a collaborative design co-op. With the initial goal of finding a way to harness the energy of a child to power a toy, they formed Sprig Toys in 2007, creating a line of battery-free, eco-friendly, paint-free, kid-powered toys. By pumping up and down on the smaller Sidekick vehicles, or using the push-pole attachment on the Discover Rig, children, not batteries, power the LED lights and sound narrations from the Adventure Guide characters.

To make an eco-friendly, paint-free toy, Sprig turned to wood-composite manufacturer JER Envirotech (Delta, BC) to develop the injection moldable thermoplastic biocomposite using polypropylene called Sprigwood. Bill Hunnicutt, JER’s VP of global sales and marketing, says that during the development process, several iterations of polymer bases and different concentrations of wood were tried out.

Toward the end of 2006, molding samples of trial materials took place, making prototypes of Sprig products. The toys are molded in North America by Baytech Plastics (Midland, ON), a company that molded Hula Hoops in the 1950s. “It probably took six to eight months to finalize the product with a number of tweaks, waffling between whether to use PP or PE materials, and determining the amount of wood fibers we would use,” says Hunnicutt.

Often the colors and overall appearance of toys can determine whether or not children enjoy playing with them, and Sprigwood achieves a colorful and unique look. JER has helped other toy designers like Rolco Inc. (Kasota, MN; read initial report here) design unique game pieces containing up to 50% recycled wood byproduct. “People want to differentiate their products from everybody else’s,” says Hunnicutt. “By using wood polymers and having the unique look of the wood, along with the fact that it’s recycled, you can make your product stand out significantly against others.”

JER continues to work with Sprig Toys on new material formulations for new product lines, and is even testing polymer bases other than the Sprigwood PP, such as polyethylene, polystyrene, and PPOs. “There’s an additional process we’re trying so that we can develop a final product for them that will hold as much recycled content as possible,” says Hunnicutt. “If we can achieve 95% recycled content, that would be their ideal product.”

Designing for WPCs

“Once we identified it was PP we wanted to work with, we really saw some of the properties shine through,” says Chris Clemmer, Sprig Toys cofounder and designer. “Even in the recycled form, you might see some thermal degradation, but it generally performs like a virgin material, which has been very helpful for us.” Another challenge Clemmer had when designing for Sprigwood was to make sure ribs and wall thicknesses changed slightly from a traditional plastic, to compensate for any weakening that occurs when adding wood.

The new products that Sprig showed at the TIA Toy Fair include the Sprig Hollow sand, water, and garden toys, with one product offering a set of pots with seed-infused plantable packaging. Because of the way it’s designed and made, these toys have roughly 10-20% more wood than the adventure series. “We want parents to get outside and spend time with their kids,” says Clemmer, who was the primary designer of the Sprig Hollow line. “And, since Sprig Hollow is made from recycled materials, the toys provide an opportunity to talk about caring for the earth.”

Other toys designed for the fall line include blocks that allow kids to incorporate story boards into block play, and play sets that are spinoffs of the Adventure sets but at lower price points. As for future toy designs, Clemmer would like to work with a product requiring no virgin materials. “Looking forward to what we’d consider the next generation of Sprigwood, we’d want something completely biodegradable, and not composed of petroleum-based plastics – something totally cradle to cradle.”

Although Sprig’s products comply with CPSIA regulations, the changes will likely affect the entire industry. “For us, the biggest concern we have now is with third-party lab testing requirements. The queue for having products tested is now going to be a lot longer, so it changes your development cycle to account for that,” says Sprig’s CEO Craig Storey.

Recycled, colorful fun

Another award-winning toy manufacturer introduced its expanded line of recycled plastic toys at the Toy Fair. Green Toys’ (San Francisco, CA) products, which are 100% U.S.-made, are molded from HDPE milk jugs recycled in California into tool sets, dining and tea sets, sand play sets, and even recycling trucks, for instance.

Last year Green Toys received many awards, including being named one of Parenting magazine’s 2008 Toys of the Year, and receiving the Dr. Toy’s Green Toy Company of the Year award. No BPA, phthalates, or lead paint are used in the CPSIA-compliant toys, and the company does what it can to reduce its carbon footprint by having all operations located within close proximity in Northern California.

“For 2009, we’re committed to the strategy that served us well in 2008,” says Robert von Goeben, cofounder and president of Green Toys. “We’ve responded by adding classic new products, while staying true to our core mission of providing the safest U.S.-made, eco-friendly toys.”

Achieving vivid colors while using recycled plastic can sometimes be difficult, but the custom colors designed by PolyOne (Avon Lake, OH) provide bright shades for the trucks and soft pastel hues for the housewares. PolyOne is also helping its customers with CPSIA compliance by developing a group of materials certified as PolyOne Sustainable Solutions, which meet criteria for regulatory compliance and eco-conscious composition while maintaining traditional properties and performance. These phthalate-alternative products include OnColor nonphthalate masterbatches for vinyl, Geon nonphthalate flexible vinyl compounds and vinyl plastisols, Wilflex inks, and PolyOne alternative plasticizers.

Time will tell if current toy manufacturers are able to comply with the rules, or if the high cost associated with product testing will force restructuring in the business. With the help of an increasing amount of eco-friendly materials on the market, some forward-thinking toy designers have tackled the challenges and developed safe and fun toys.

WEB EXCLUSIVE

Website tracks toxic toys

"There is simply no place for toxic chemicals in children's toys," said Ecology Center's (Ann Arbor, MI) Jeff Gearhart, who led the research for the second annual consumer guide to toxic chemicals in toys at HealthyToys.org. The Ecology Center is a nonprofit environmental organization working at the local, state, and national levels for clean production and environmental justice, and its project HealthyToys.org offers consumers a way to check the safety of specific toys. The tested toys represent a cross section of some of the most popular items played with by children in the United States, and the X-ray fluorescence testing device measures not only lead content, but also harmful elements such as arsenic, chromium, and mercury.

Searchable results are posted on the website for products such as the popular Thistle Blocks from Edushape Ltd. (Rosh Haíayin, Israel), which showed high levels of lead and arsenic, medium mercury levels, and the presence of chromium. While the most contaminated product category tested was childrenís jewelry, HealthyToys.org found that 27% of toys tested in 2008, excluding jewelry, were made with PVC, which may contain hazardous additives, including phthalates. Though many recent reports target toys manufactured in China as the biggest threat, HealthyToys.org says that of the 2800 toys it tested in the last two years, a consistent correlation has not been found between country of manufacture and the presence of toxic chemicals in the toys. —[email protected]

About the Author(s)

You May Also Like