The Medalist MD-23100 compounds from Teknor Apex (Pawtucket, RI) reportedly provide long-term seal integrity at lower cost than thermoset rubber.

July 26, 2017

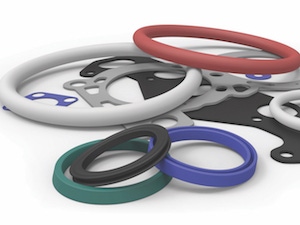

New medical-grade thermoplastic vulcanizate (TPV) elastomers from Teknor Apex (Pawtucket, RI) for injection molded O-rings, gaskets and diaphragms exhibit long-term sealing performance, cost less to process than thermoset rubber, and provide manufacturing advantages over standard TPVs and styrenic TPEs, according to the company.

New medical-grade thermoplastic vulcanizate (TPV) elastomers from Teknor Apex (Pawtucket, RI) for injection molded O-rings, gaskets and diaphragms exhibit long-term sealing performance, cost less to process than thermoset rubber, and provide manufacturing advantages over standard TPVs and styrenic TPEs, according to the company.

The Medalist MD-23100 compounds provide rubber-like elasticity, long-term compression set and chemical resistance. Unlike some standard TPVs, compounds in the new Medalist series are non-hygroscopic, rendering pre-drying unnecessary. Their lighter natural hue makes them easy to color. The compounds also exhibit better high-temperature stability than styrenic TPEs, said Teknor Apex.

The compounds are available with Shore A hardness levels from a soft 15 to a semi-hard 73; melt flow rates can reach 24 g/10 minutes. The new TPVs are suitable for molding small, high-precision parts in complex, multi-cavity tools, and can be over-molded onto polypropylene.

Teknor Apex recommends the new compounds for sealing components used in devices for drug delivery, fluid transfer, dialysis, endoscopy, and other procedures, as well as feeding devices and pumps.

“The dynamic sealing properties of Medalist MD-23100 Series TPVs enable device manufacturers to obtain excellent long-term performance while avoiding the higher cost and greater complications associated with processing thermoset rubber,” said Ross van Royen, Senior Market Manager for regulated products. “At the same time, these new compounds provide processing advantages over a number of TPV and styrenic TPE candidates for seal applications.”

Teknor Apex produces Medalist MD-23100 Series compounds in ISO 13485–certified facilities in the United States and Singapore. The materials comply with FDA requirements for food-grade ingredients, ISO 10993-5 standards for biocompatibility, and REACH SVHC directives. They are free of DEHP and other phthalates, BPA and latex. Standard grades are ADM-free.

About the Author(s)

You May Also Like