Mayzo’s Beta Technology Helps Thermoformers Overcome Polypropylene Cost and Supply Challenges

The technology allows thermoformers to use less resin to produce the same amount of product and improve productivity by as much as 25%.

April 8, 2021

As polypropylene resin prices continue to fluctuate, thermoforming plastics processors are looking for new cost-effective and sustainable solutions. Mayzo Inc., a provider of specialty chemical additive solutions based in Suwanee, GA, offers thermoformers the advantages of its proprietary Beta Technology, a beta nucleating masterbatch that enables processors to use less resin while producing more product faster.

“Thermoforming customers are achieving two substantial advantages through the use of Mayzo’s Beta Technology,” said Philip Jacoby, an expert in polypropylene and retired VP of Technology at Mayzo. “First, they are achieving down-weighting of at least 15%. That means less polypropylene resin is required to produce the same amount of end product.

“Second, they are realizing a productivity improvement of up to 25%. This faster cycle rate is proving especially valuable for Mayzo’s customers in the rigid food packaging business, who also appreciate the masterbatch’s broad food-contact approvals.”

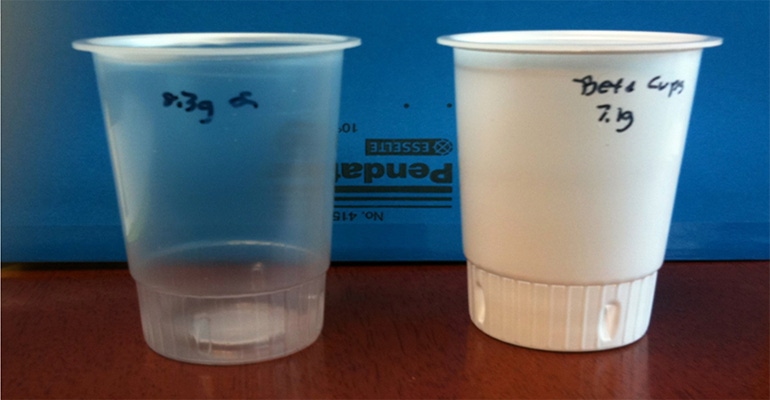

These benefits help thermoformers meet today’s challenges, including rising resin costs, transportation difficulties, supply disruptions, and sustainability imperatives, noted Mayzo’s announcement. Other benefits include a dramatic reduction or even elimination of TiO2 pigments used to make white containers, a “boon to processors who are committed to meeting sustainability goals,” said Mayzo. Additionally, by eliminating white pigments from the product, the post consumer resin (PCR) recovered has higher value.

About the Author(s)

You May Also Like