NPE, Pack Expo, ChinaPlas: A summary of packaging coverage

The industry came out in full force to various expos and conferences throughout the year. From NPE to Chinaplas to Pack Expo, PlasticsToday was there reporting on breaking news, new product launches and industry trends.Here's a look back at some of the coverage.The Packaging ConferenceAll about the package: Companies discuss packaging designs

December 21, 2012

The industry came out in full force to various expos and conferences throughout the year. From NPE to Chinaplas to Pack Expo, PlasticsToday was there reporting on breaking news, new product launches and industry trends.

Here's a look back at some of the coverage.

The Packaging Conference

All about the package: Companies discuss packaging designs

Las Vegas, NV - Sometimes, it's what's on the outside that counts."Packaging is the number one medium to communicate the brand," said Michael Okoroafor, VP global packaging at H.J. Heinz. At The Packaging Conference (Feb.  6-8; Aria City Center; Las Vegas), packaging was the star of the show as several speakers talked about its importance to an overall brand. It's no secret that supermarket shelves are cluttered with an endless array of choices. As a result, many of the world's biggest brands continue to search for ways to make its product distinct by using various packaging designs and materials.

6-8; Aria City Center; Las Vegas), packaging was the star of the show as several speakers talked about its importance to an overall brand. It's no secret that supermarket shelves are cluttered with an endless array of choices. As a result, many of the world's biggest brands continue to search for ways to make its product distinct by using various packaging designs and materials.

Sustainability, innovation, and partnerships key themes at The Packaging Conference

Attendees of The Packaging Conference (Feb. 6-8; Aria City Center; Las Vegas) saw a different type of green in Las Vegas, as sustainability, versus greenbacks, seemed to be on the mind of most. In fact, almost all of the speeches touched on sustainability at point or another. Ecologic Brands chief innovation and packaging officer Glenn May told PlasticsToday how sustainable practices are, in part, driven by consumer demand. "Consumers are smart, and the next generation does care and read labels," he said. "We make sure we are doing our homework and are producing products that are truly better for the environment."As expected, the importance of innovation in the industry was also discussed frequently.

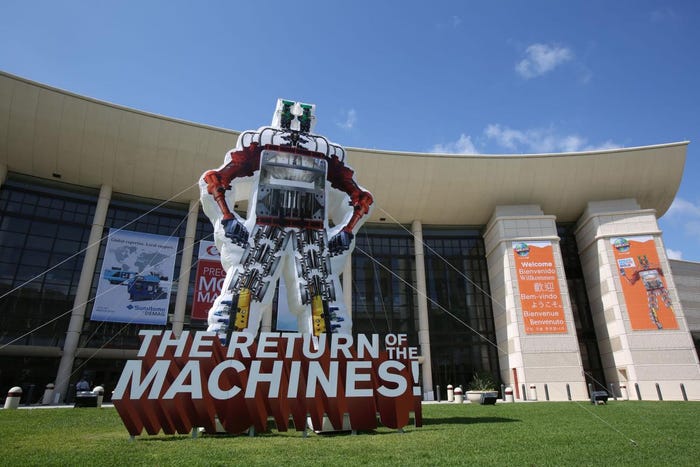

NPE2012

NPE2012 is on track to surpass recent NPEs

About 1900 companies are exhibiting at NPE2012 (April 1-5; Orlando, FL), which is significantly more than NPE shows in 2006 and 2009, according to leaders with SPI: The Plastics Industry Trade Association, which produces the triennial NPE. NPE2012 opened its doors Monday morning to a new location for the first time in 40 years. "This is one of the best moves the plastics industry ever made," John Effmann of ENTEK Manufacturing Inc., and chairman of NPE2012, said to members of the media at a press breakfast.

members of the media at a press breakfast.

Kautex touts rapid prototyping for packaging applications, R&D operations

Orlando, FL- Kautex Machines Inc. discussed with PlasticsToday at booth (#1751) its rapid prototyping for packaging applications, which includes a patent-pending shell insert system. Through rapid prototyping and simulation, Kautex can produce a blowmolded sample within 48 hours from receiving the 3D CAD drawing, said Chuck Flammer, VP sales at Kautex. Traditionally this process takes about six weeks, Flammer said. "We believe it is a competitive advantage," he said.

Engel eyes top spot in cap machines with all-electrics

Engel demonstrated a high-powered, all-electric cap-molding cell at NPE2012 and disclosed its goal of becoming number one in the bottle cap production niche. "Our cap business is growing 30% a year," said Dr. Peter Neumann, CEO of Engel (Schwertberg, Austria) at a press conference, adding: "Our goal is to become number one in the cap business." An all-electric ENGEL e-cap 3440/460 US injection molding machine at the show in Orlando, FLA uses a 96-cavity mold, with an hourly production rate of almost 130,000 high-density polyethylene water bottle caps. Cycle time is a crisp 2.7 seconds.

Proco unveils take-out system with integrated deflasher and leak tester

Orlando, FL-Proco Machinery Inc. has developed a take-out system with an integrated deflasher and leak tester. The company demonstrated this new "all-in-one" multi-functional system for extrusion blowmolded bottles at NPE2012 booth (#542). "This is a very unique system and is an industry first," Savi Krish, sales manager with Proco, told PlasticsToday. "This takes three functions and puts it into one station."

Kraiburg launches two new classes of materials

Orlando, FL - Kraiburg TPE, the global supplier of thermoplastic elastomers (TPEs), launched two new classes of materials designed for the consumer electronics industry at NPE2012 booth (#61027). The new olefin block copolymer (OBC) blends offer strong mechanicals, skin oil resistance, and enhanced bond strength to high-performance glass-filled nylon substrates, the company stated. These OBC blends are available in 60-80 Shore A hardness range, and offer resistance to sebum, olive oil, sunscreen lotion, and other oils. In addition, the OBC compounds exhibit adequate flow properties, which result in improved extrusion capabilities, along with better colorability, according to Kraiburg.

Dow Chemical packaging division introduces new resins

Orlando, FL - The Dow Chemical Co. introduced new resins for the North American packaging market at NPE2012. Greg Bunker, senior group marketing manager for food and specialty packaging at Dow, told PlasticsToday that the company is always looking for new ways to make a better package."We work closely with our customers to offer innovations that help enable the next generation packaging," he said.

Mold-mounted coinjection unit generates buzz for Mold-Masters

Mold-Masters is utilizing its E Multi mobile injection unit to empower its new Iris coinjection technology, letting injection molders bring coinjection capabilities to any machine in their shop with a system that actually attaches to the tool itself. At NPE, the hot-runner and injection molding technology supplier displayed the innovative concept in two booths, running a 38-mm high-density polyethylene (HDPE) cap with an integrated EVOH barrier, as well as at JSW's booth, molding a PP container with EVOH barrier coinjected from the gate all the way through the containers' lip and foil seal area.

Companies talk sustainability, transparency at NPE2012

If there was a color trend at NPE2012, green took home the prize. Exhibitor after exhibitor seemed to showcase some type of sustainable product, process, and outlook with the usages of green carpets, signage, and plenty of green marketing material. Shanna Moore, DuPont's director of global sustainability, called sustainability the current "phrase du jour" for the plastic packaging industry."If you walk down these halls, you see 'green that' and 'eco this,'" she said. "But there must be transparency behind the sustainable claims."

Labels key to IML success demonstrated at NPE

If you thought IML was still a "niche" application in the plastics packaging industry, think again. Printing Company Verstraete, a Belgium-based global supplier of labels for IML applications had the company's products running in IML molding applications in seven molding machinery booths: Negri Bossi (450g cup), Engel (1-liter ice cream tub with Bi-color lid), Illsemann (250g Eurotub running in a Netstal press), Toshiba (200g cheese container), Wittmann Battenfeld (metallic labeled butterbox), Arburg (pail with handle representing demand for larger packaging requirements), and Wetec/Jonwai (700 ml oval container and lid).

NPE2012 Packaging Overview: Machines

NPE2012 Packaging Overview: Machines

There was roughly about 15 million pounds of freight shipped into the Orange County Convention Center at NPE2012, according to SPI. The energy usage for the machinery was a new record for the OCCC, which invested $4 million to get ready for the show. As PlasticsToday has provided NPE2012 coverage before, during, and after the show, here's a collection of various packaging machinery and technology at NPE2012: David-Standard said its triple lip air ring provides fast gauge control via the manipulation of all three airstreams; battenfeld-cincinnati USA introduced its new multi-touch roll stack, suitable for PP extrusion; and Addex Inc. unveiled two new gauge-control enhancement systems to help processors optimize the bubble control system, reduce scrap, and meet product specifications.

NPE2012 Packaging Overview: Materials

Not to be outdone by the machines, there was an abundance of new resins, compounds, and additives on the exhibit floor at NPE2012. "There is more participation by resin manufacturers than we've seen in the last four or five NPEs, as these companies exhibit, host customer service centers, or sponsor special-interest initiatives such as our design competition," said SPI's Gene Sanders, Sr. VP, trade shows and conferences. Sustainability seemed to be a key theme among many material suppliers.

Chinaplas

Titanium-based additive reduces PET reheat blow energy by 38%

An independent comparative study carried out by stretch blowmolding machine vendor Sidel (Le Havre, France) has shown that Joule RHB titanium nitride-based PET reheat additive from ColorMatrix (Knowsley, UK), offers the largest carbon footprint reduction in PET preform processing, while maintaining superior performance and aesthetic qualities. Joule RHB is compounded into PET resin by the supplier during the polymerization process. ColorMatrix also offers a similar product known as SmartHeat, which can be added by the processor to the PET melt at the preform injection stage.

Husky unveils new closure molding concept in Shanghai

One surefire way to cut cycle time in injection molding is to shorten or eliminate process steps. Working from that simple premise, Husky Injection Molding debuted a revolutionary closure technology at Chinaplas 2012 that eliminates mold open/close and the precious seconds that process eats up. Behind a locked glass enclosure, into which attendees could only gain entrance with a special Husky supplied badge, the supplier operated a HyCAP HPP 300 machine injection molding a 1.2g 29/25 lightweight water closure in a 1.85 second cycle from a 72-cavity KTW mold. Husky acquired KTW, an Austria-based closure moldmaking expert, in 2011.

TAPPI PLACE Conference

Conference speakers, attendees discuss the future of flexible packaging

Seattle, WA - Almost half of attendees at the 2012 TAPPI PLACE Conference believe materials will be the next source of innovation in flexible packaging. "There's quite a bit of innovation in material," Brad Rogers, director of advanced research at PepsiCo, told TAPPI PLACE attendees. "But equipment also plays a key role."However, Ampac Director of Innovation Sal Pellingra believes design will lead the way for flexible packaging innovation. The TAPPI PLACE (May 6-9; Grand Hyatt Seattle) Conference kicked off with a discussion about the future of flexible packaging. Part of the interactive session was gauging the audience's viewpoint of several critical topics facing the industry.

Starbucks, ConAgra Foods talk packaging sustainability initiatives, challenges

Seattle, WA - As TAPPI attendees sipped on white coffee cups with a green siren logo, Brent Denniston, Starbucks VP of global procurement, said the company is fully aware of the profound effect of its packaging."Our packaging is an asset, but it's also a liability," Denniston told TAPPI members and attendees. "Packaging waste is the number one environmental issue to many consumers."At the TAPPI PLACE (May 6-9; Grand Hyatt Seattle) Conference, Denniston and Gail Tavill, vp of sustainable development for ConAgra Foods, both spoke about packaging for their brands. The topic of packaging sustainability and recycling were prevalent in both speeches.

Pack Expo

Dow touts collaboration efforts; launches new products Chicago, IL

Inside Dow Chemical's customer care center, Scott Collick, director of Dow's performance packaging TS&D, highlighted the importance of collaboration."Feel the energy in here," Collick told PlasticsToday. "There are new packaging ideas being created this very minute."At Pack Expo 2012 (October 28-31; McCormick Place, Chicago), you won't find employees of Dow manning a booth. Instead, the company sponsors a customer care center, located in the Vista Ballroom, in an effort to meet with its customers in a setting that is designed to promote collaboration.

After IPO, Berry Plastics focuses on innovation

After IPO, Berry Plastics focuses on innovation

While there are many large plastic packaging companies at Pack Expo (October 28-31; McCormick Place, Chicago), only one had just announced an initial public offering (IPO), sized at $470 million.Berry Plastics had recently priced an IPO of 29.4 million shares of its common stock at $16.00 per share. Under the New York Stock Exchange symbol BERY, the stock price drifted lower and currently trades at around $14/share. On the last day of Pack Expo 2012, Eric Metcalf, business and market development manager for Berry Plastics, told PlasticsToday that the show has gone well for the packaging giant.

Rollprint showcases color-changing sealant technology; talks cleanroom certification

Chicago, IL-"We've been bombarded." That's how Joel Lewis, account manager for Rollprint Packaging, described to PlasticsToday the level of interest at Pack Expo (October 28-31; McCormick Place, Chicago) for the company's new proprietary, patent-pending, color-changing sealant technology for heat-seal applications.Called the Chameleon, the coextrusion-coated sealant can be applied to any thermally stable web including polyester, nylon, and polypropylene, or on any of the company's ClearFoil barrier structures.

For material producers, sustainability remains at the forefront of packaging innovation

There is certainly both an environmental and business case for sustainable materials. The global green packaging market is expected to grow from $109 billion in 2011 to reach nearly $178 billion by 2018, according to Transparency Market Research. Among the key factors behind the move toward green packaging are growing awareness about carbon emissions, energy consumption and waste reduction targets, rapidly growing economies, a lack of natural resources, and consumers' preference for ecologically clean products. With such high growth potential, it's no wonder that the term sustainability was referenced frequently among companies at Pack Expo 2012 (October 28-31; McCormick Place, Chicago).

Clear Lam looks to stack up success with new packaging technologies

Chicago, IL-The folks at the Clear Lam Packaging booth at Pack Expo 2012 (October 28-31; McCormick Place, Chicago) were scrambling. Not due to disorganization or "putting out fires," but rather they were trying to find more information sheets for its PrimaPak product line."It's been such a huge hit at this show that we've run out of sales sheets," Roman Forowycz, chief marketing officer for Clear Lam, told PlasticsToday. Calling it the most "exciting environmental packaging to date," the PrimaPak product line offers a flexible, stackable replacement for rigid containers, bottles and jars.

Packaging schools work to boost youth's engagement with the field

Chicago, IL - Brian Welt, coordinator of the University of Florida's packaging-engineering program, believes many students share a common misconception when it comes to packaging jobs."A lot of students don't even know it's a career," he told PlasticsToday at Pack Expo 2012 (October 28-31; McCormick Place, Chicago). "And, as a result, they don't realize how great the opportunities are for the industry."The most important asset for any company is its workforce. If you measure on the basis of gross sales, packaging is the world's third-largest industry, featuring a variety of jobs from engineering to design to the conversion of raw materials. Still, projections show that the need for skilled packaging professionals far exceeds the number of packaging graduates.

Expoplast

Fighting bag bans, encouraging recycling-just another day at CPIA

Montreal, Quebec-When Carol Hochu took office as the president and CEO of the Canadian Plastics Industry Association, she knew she would have her hands full. "We represent an industry that is largely responsible for the quality of modern life for all Canadians," she told PlasticsToday at Expoplast (November 14-15; Palais des congrès de Montréal; organized by PlasticsToday parent, UBM Canon). "Still, the industry faces several challenges and oppositions." CPIA is Canada's version of the Society of the Plastics Industry (SPI). Just like SPI, the organization works to grow the plastics industry to help it reach its full potential, by providing one unified voice.

About the Author(s)

You May Also Like