Thin-Wall Injection Molding Breakthrough for rPET

Engel and partners’ development yields thin-walled food containers made in a single injection-molding step using up to 100% recycled PET.

For the first time, thin-walled containers made of PET, specifically recycled PET (rPET), can be produced in a single injection-molding process step.

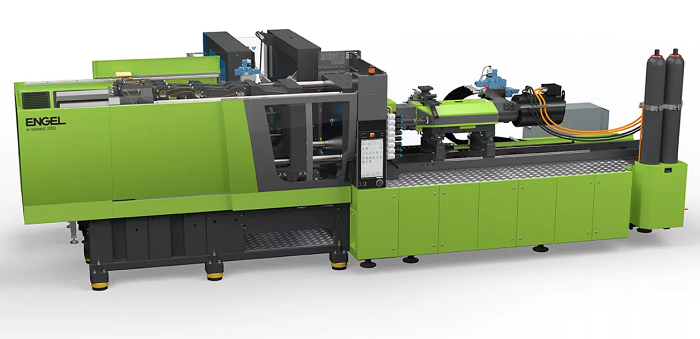

In cooperation with partners Alpla Group, Brink Recycling, IPB Printing, injection molding machine manufacturer Engel is presenting a step forward for the packaging industry at K 2022 by processing recycled material, rPET, at its stand. Featured will be an Engel e-speed injection molding machine with a newly developed and extremely powerful injection unit.

Featuring a wall thickness of 0.32mm/0.013 inch, the transparent, round 125-mL containers are representative of a whole category of plastic packaging, especially in the food industry.

An Engel spokesperson tells PlasticsToday that, among others, “the [rPET] cups can be used for food products such as dairy products, gourmet salads, or sandwich spreads.”

With the use of integrated in-mold labeling (IML), the containers are ready-for-filling as soon as they leave the production cell. The special feature in this application is the material. The thin-walled containers are produced directly from rPET in a single step.

Until now, it has only been possible to process PET in thick-walled parts such as bottle preforms in injection molding. In that standard process, the final packaging format was created in a second step of the process — by blow molding, for example.

Under the European Plastics Pact, the intent is for all plastic packaging to contain 30% recycled material and to be 100% recycling capable by 2025. Typical materials used for packaging foods in thin-walled containers are polyolefins (polyethylene, polypropylene) or polystyrene.

However, experts believe it's impossible to achieve the stated objectives using PE, PP, or PS.

Also, recycling schemes for these materials lack the approval of the European food authority, European Food Safety Authority (EFSA). rPET offers a solution for avoiding penalties and special taxes. Although the price for PET is currently high, this concept makes the material a cost-effective alternative. EFSA has approved numerous recycling processes for PET, thus ensuring that rPET is available in Europe.

“PET offers the benefit of having closed-loop recycling system already in place.”

To date, PET is the only packaging material which can be processed as a recycled material on an industrial scale to create food packaging. This innovation sees partner companies pave the way for removing the need to downcycle packaging products other than bottles, and opens an opportunity for recycling or upcycling. This would substantially extend the range of uses for PET and rPET. In addition to the bottle-to-bottle cycle, this also means that the establishment of bottle-to-cup or even a cup-to-bottle recycling is conceivable.

Injection molding at 1,400 mm/55 inches per second.

The modified rPET being processed at the K show is sourced from PET beverage bottles recycled in the plants of packaging and recycling specialists ALPLA Group, which is headquartered in Hard, Austria. Other partner companies involved in the show exhibit are Brink (Harskamp, Netherlands) for the mold and IML automation and IPB Printing (Reusel, Netherlands) for the labels.

An Engel e-speed 280/50 injection molding machine is the heart of the production cell. Engel specifically developed this hybrid machine with its electrical clamping unit and hydraulic injection unit for the high-performance requirements of thin-wall injection molding.

The new model 280 e-speed high-performance injection unit for K 2022 (shown above) achieves injection speeds up 1,400 mm/55 inches per second at a maximum injection pressure of up to 2,600 bar when processing small shot weights with an extreme wall-thickness-to-flow-path ratio.

To process rPET, Engel combines the new injection unit with a plasticizing unit from in-house development and production specifically designed for processing recycled material. During plasticizing and injection, the viscosity of the PET is configured for thin-wall injection molding. The new Engel e-speed supports the processing of arbitrary recycled materials up to 100% rPET.

Engel is presenting a mold at the K show which can process different labels at the same time. This sees the partners respond to the globally different trends in in-mold labeling which are in line with the EPBP and/or Recyclass recommendations in the EU, and with the specifications from the Association of Plastic Recyclers (APR) for the USA.

The dyes used on in-mold labels for the American market and its requirements can be washed off as the intent is to recycle the labels and the packaging.

A different technology is used in Europe: an in-mold label that floats during the recycling process makes it easy to separate the dyes and the label from the PET.

Engel will present this technology and other developments at K 2022 in Düsseldorf, Germany, from Oct. 19 to 26, in booth C58 in Hall 15.

About the Author(s)

You May Also Like