Antimony-trioxide-free laser-marking system tags livestock ears

High-contrast, high-speed marking of TPU tags with new masterbatch contains metalloid chemical plus special enhancing agent.

January 2, 2020

Clariant is introducing a new antimony-trioxide-free system for molding and laser-marking thermoplastic urethane (TPU) ear tags used for identifying cattle and other livestock. Working with Coherent, Inc., one of the world’s leading laser technology companies, Clariant was able to develop an additive masterbatch that, when added to the TPU commonly used to mold ear tags, makes the polymer more receptive to the near-infrared laser light from Coherent laser markers. It does so without antimony trioxide (ATO), the ingredient most commonly used to facilitate laser marking of TPU.

|

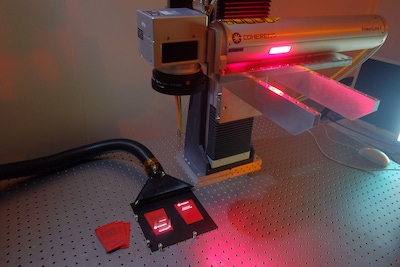

Clariant’s new additive – supplied as a concentrated masterbatch for addition to plastic at a dosage of 2–4% – helps the laser create easily readable, scannable, and permanent laser markings that cannot be washed away or dissolved by solvents or oils. Image courtesy of Clariant. |

Instead of ATO, which is classified by ECHA (European Chemical Agency) as Carc. 2, H351 (suspected of causing cancer by inhalation), the Clariant additive masterbatch uses another metalloid chemical plus a special enhancing agent. The proprietary solution is currently pending patent approval.

The Clariant ear-tag system produces high contrast images at marking speeds at least as high as those associated with tags containing ATO additives, thus offering an easy, more sustainable alternative for ear-tag production. The Coherent PowerLine F 100 W air-cooled laser marker did the actual marking. The PowerLine F Series laser sub-systems combine fiber laser technology with beam processing and software, providing high speed, precision, flexibility and user-friendliness.

Compared to printing, laser marking is a superior process for creating bar codes, text and other identifying marks on animal tags. However, unmodified TPU is essentially transparent to near-infrared laser light, so the carbonization and/or foaming reaction required to make a laser mark does not occur. The new Clariant additive – supplied as a concentrated masterbatch for dosing into virgin polymer at a rate of 2–4% – helps the laser create easily readable, scannable, and permanent laser markings that cannot be washed away or dissolved by solvents or oils.

Ear tags are in everyday use around the world. In the European Union, all cattle are required by law to have official ear tags in both ears to enable computerized location tracking. The tags are typically large and carry a lot of information, so it is important that the Clariant additive allows the laser to create high-quality images quickly. Tags may combine laser markings and RFID inserts to simplify the collection of tracking information.

Clariant is well-known for its laser-friendly additive packages which have also been developed for marking of flexible packaging film – especially polyethylene (LDPE, LLDPE) – as well as medical and automotive components that require individualized identification. Coherent is one of the world’s leading providers of laser-based technologies, offering a comprehensive portfolio of lasers, laser sub-systems, and laser machines for a broad range of commercial, industrial, and scientific applications. “Both partner companies are global,” explains Chun-Yip Pang, Clariant’s Global Product Manager Additive Masterbatches – Laser, “which means we can provide a complete and consistent supply chain worldwide.”

About the Author(s)

You May Also Like