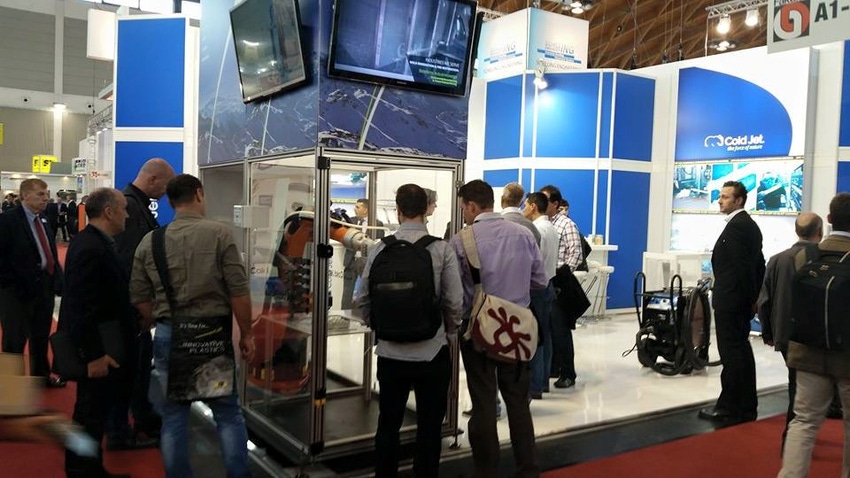

Cold Jet showcases new Plastics Edition range at Fakuma 2015

The new Plastics Edition, specifically tailored for end users in the plastics industry, where mold cleaning issues are rife, is based on Cold Jet's (Loveland, Ohio) existing Aero Series of dry ice cleaning systems. The series has now been improved, and the Plastics Editions are delivered with a range of purpose designed accessories, said Cold Jet. The new equipment is designed to provide excellent pellet integrity, the highest levels of cleaning aggression and the most reliable blast stream currently available on the market.

October 19, 2015

The new Plastics Edition, specifically tailored for end users in the plastics industry, where mold cleaning issues are rife, is based on Cold Jet's (Loveland, Ohio) existing Aero Series of dry ice cleaning systems. The series has now been improved, and the Plastics Editions are delivered with a range of purpose designed accessories, said Cold Jet. The new equipment is designed to provide excellent pellet integrity, the highest levels of cleaning aggression and the most reliable blast stream currently available on the market. The Plastics Edition benefits from the 30 years of experience which Cold Jet has built up in dry ice cleaning in many different industrial sectors.  As the company points out, clean molds are a critical component of producing quality end products, but traditional cleaning methods involve tedious and ineffective manual processes using chemicals and hand tools. Dry ice blasting offers a non-abrasive and environmentally responsible alternative that allows molds and product to be cleaned in a fraction of the time, allowing increased cycles between preventive maintenance. In addition, molds can be cleaned at operating temperature and in-place, without water, chemicals or creation of secondary waste. It is a dry process which leaves no secondary residue. Dry ice cleaning improves the quality of finished goods. It utilizes the same food grade CO2 used in carbonated beverages.

As the company points out, clean molds are a critical component of producing quality end products, but traditional cleaning methods involve tedious and ineffective manual processes using chemicals and hand tools. Dry ice blasting offers a non-abrasive and environmentally responsible alternative that allows molds and product to be cleaned in a fraction of the time, allowing increased cycles between preventive maintenance. In addition, molds can be cleaned at operating temperature and in-place, without water, chemicals or creation of secondary waste. It is a dry process which leaves no secondary residue. Dry ice cleaning improves the quality of finished goods. It utilizes the same food grade CO2 used in carbonated beverages.

The cleaning system is suitable for use with all kind of molds and tools. In-machine cleaning is also possible. Besides cleaning, it can also serve as what Cold jet calls an “automated surface preparation solution”: the system can eliminate the need for power-washing or chemical cleaning product surfaces prior to painting. It can also safely remove flash and burrs from a variety of materials, including PEEK, PBT, Acetal, ABS etc., without causing part surface damage.

Cold Jet says that the new designs offer reduced wear, which prolongs the machine life time. They feature a lightweight, compact and energy-efficient motor; a new rotor design that provides pulse-free blasting and precise feed rate control, and an integrated pressure regulator.

At the Fakuma, Cold Jet demonstrated on-site just how much time dry ice cleaning can actually save. According to the company, a mold can typically be thoroughly cleaned, in all cavities, in only 15 to 20 minutes, which increases efficiency and frees up employees for other production activities. Also, Steve Wilson, Managing Director of Global Vertical Markets at Cold Jet presented the Cold Jet dry ice cleaning benefits at the Exhibitor Forum during the Fakuma tradeshow. He summed it up by saying: “Using dry ice cleaning offers improved part quality, fewer rejects, increased productivity because of longer uptime, extended asset life because of the non-abrasive nature, so no damage to molds, and a faster clean with zero waste and no solvents. This adds up to better quality, more productivity and lower costs for the end user.”

What’s not to like?

About the Author(s)

You May Also Like