Gloucester Engineering expands bag machine rebuild services

Rebuilding and retrofitting old bag making machines is nothing new to Gloucester Engineering Co. Inc. (GEC), which has long been a service the company has offered, but recently GEC expanded the capabilities of this service.GEC can now take a used bottom-seal bag machine of any age, and from any OEM, and upgrade, retrofit, and remanufacture it with the latest servo drive and control package.

April 9, 2014

Rebuilding and retrofitting old bag making machines is nothing new to Gloucester Engineering Co. Inc. (GEC), which has long been a service the company has offered, but recently GEC expanded the capabilities of this service.

GEC can now take a used bottom-seal bag machine of any age, and from any OEM, and upgrade, retrofit, and remanufacture it with the latest servo drive and control package.

"This type of services fits directly into the offer we want to develop for our lifetime support division," Laurent Cros, president of GEC's lifetime support division, told PlasticsToday."These bag machines are not only brought back to a condition comparable to a new machine, but they are upgraded to the latest technology, in particular servo drives replacing the older hydraulic technology. This program satisfies customer demands to increase their line speeds, and do away with the increasing cost of maintaining hydraulic machine and the expense of handling hydraulic fluids."

Rebuilding is cost effective for customers who get machines in a comparable condition, saving tens of thousands of dollars compared to investing in new ones, Cros said. Upgrading to the servo driven design also alleviate the expense of purchasing and handling hydraulic fluids.

Using trained factory labor and OEM certified parts, GEC retrofits include a replacement of all hydraulic components with a 4-axis servo drive package that controls bag length, shuttle motion, web tension, and head travel; a new touch screen console for machine operation and control; new operator controls with software tools for remote diagnosis, troubleshooting, and recipe storage; and more.

"There are literally thousands of those machines running around the world and particularly in North America," Cros said. "Since we reintroduced the service and given the quality of the machines we have been delivering, demand has been really strong. It is also notable that we have worked on machines from other manufacturers and was able to bring them to our OEM condition. Not everyone can do this and this contributes to the growth in rebuilds at our facilities in Gloucester, MA."

Due to shipping delays and costs, Cros said GEC is mainly serving the North American market but the company is looking into ways to expand to more distant markets. For example, GEC is considering rebuilding machines for stock that could be used in an exchange program.

|

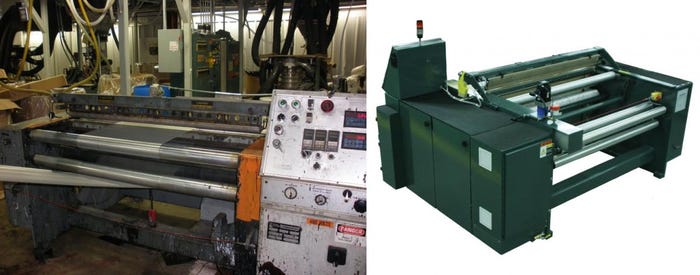

'Before and after' photo showing a worn-out bag making machine as it came in to Gloucester Engineering, next to a rebuilt machine. |

About the Author(s)

You May Also Like